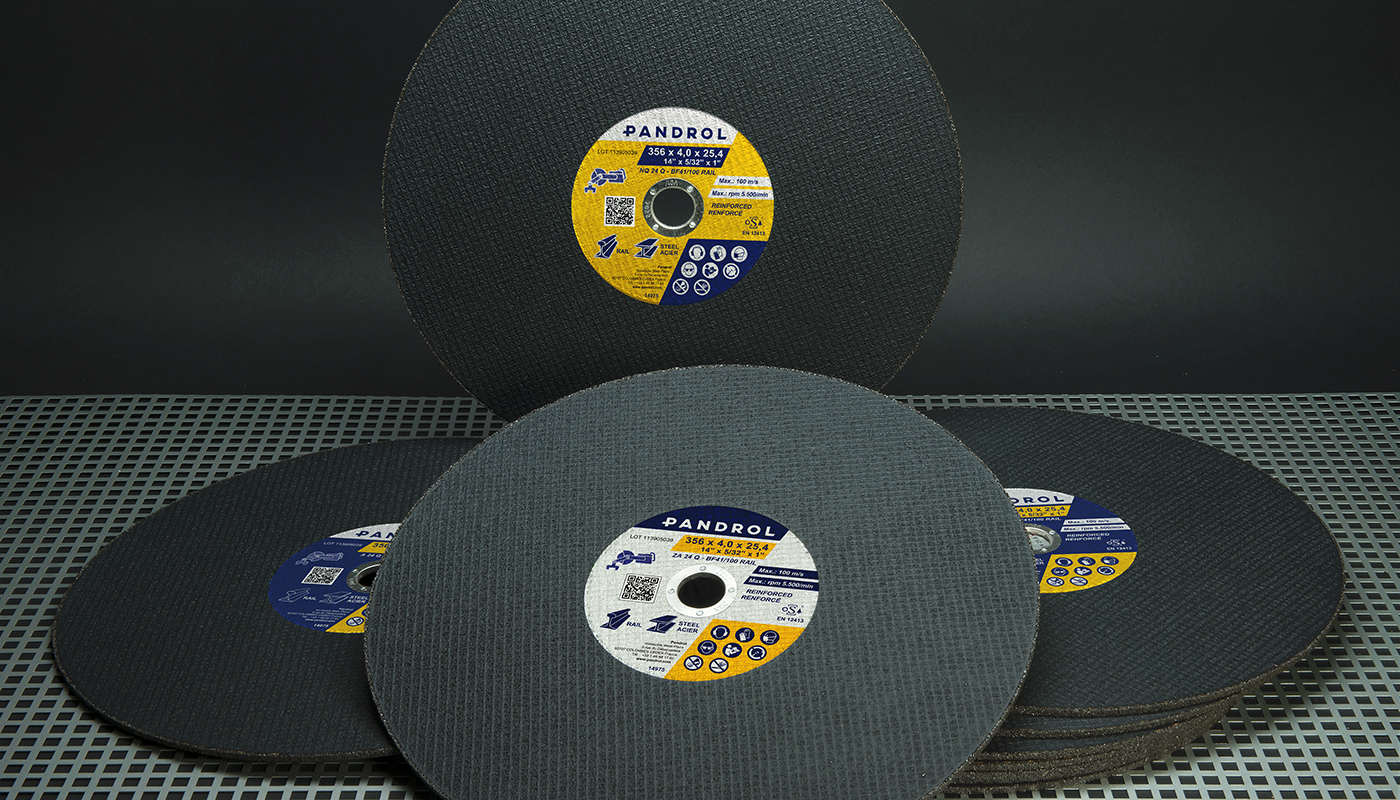

Rail Cutting Discs

Pandrol’s range of Rail Cutting Discs has been designed for ease of use, durability and effective cutting. All three products in the range have a longer life than other products on the market, which reduces the number of replacement discs needed and saves time and money.

As rail track technology continues to make major advances to cope with increasing axle weight and tonnage, the steel used for tracks has become purer and harder. This, combined with high levels of carbon, manganese and silicon and the heat treatment used in manufacturing, has made cutting operations an increasing challenge. At Pandrol, we recognised that rail maintenance teams needed a new, powerful solution for cutting heavy duty steel track.

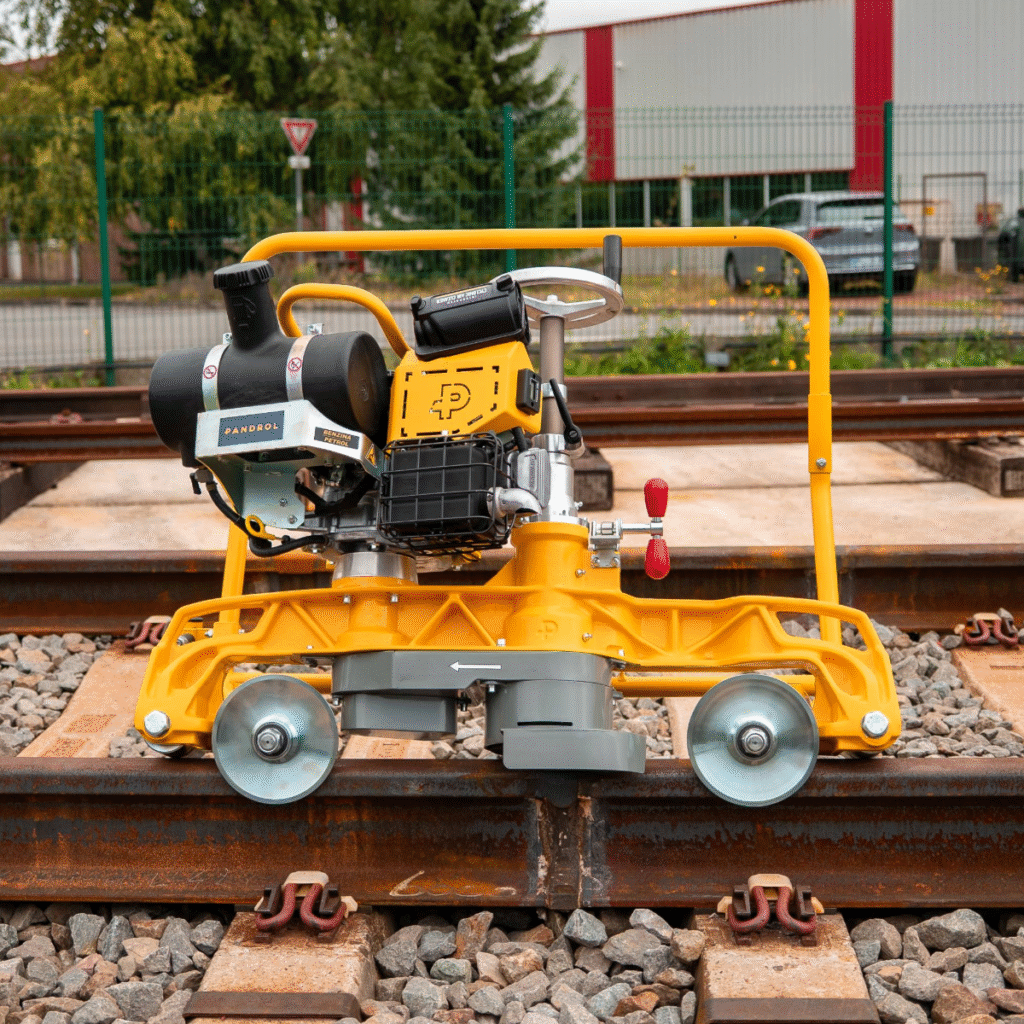

Pandrol’s HC 355 Rail Saw is compatible with all three cutting discs in the range and ensures fast, accurate and safe cutting of all rail profiles and grades.

Rail Cutting Discs product overview

At Pandrol, we recognised that rail maintenance teams needed a new, powerful solution for cutting heavy duty steel track. Pandrol’s HC 355 Rail Saw is compatible with all three cutting discs in the range and ensures fast, accurate and safe cutting of all rail profiles and grades.

- As rail track technology continues to make major advances to cope with increasing axle weight and tonnage, the steel used for tracks has become purer and harder

- This, combined with high levels of carbon, manganese and silicon and the heat treatment used in manufacturing, has made cutting operations an increasing challenge

Downloads

Benefits of the Rail Cutting Discs

Increased productivity

Improved productivity when cutting rails, making track renewal projects quicker to carry out

Cost saving

Reduces the total cost of maintenance thanks to longer life discs and quicker on track times

Safer

The reduced vibration from the disc makes the cutting operation safer for the operator

Longevity

Longer disc life reduces the environmental impact of maintenance work

Technical features of the Rail Cutting Discs

Compatible

Compatible with the HC 355 Rail Disc

Two specifications available

The discs are available in two specifications: Alox and Zirconia

Thickness

All of our discs have a thickness and bore of 4.0 x 25.4 mm

Related products

The Pandrol SolidGrinder-P-150-VIR has been designed to fully grind the rail head after welding. Like all of Pandrol’s grinding machines, it combines power and reliability with ease of use.

SolidGrinder-P-150-VIR

The Pandrol Frog/Profile Grinder delivers accurate rail and frog grinding with ergonomic roll-over control. Its lightweight frame and optional outrigger make it a flexible solution for precise weld finishing in the field.

Frog Profile Grinder (05900-05950)

The Pandrol Diesel Powered Unit (02900A) provides reliable hydraulic output of 5 or 10 GPM for powering rail tools. Equipped with a robust 18 hp Kubota engine, it ensures dependable performance even in tough environments.

Diesel Powered Unit 10/5GPM (02900A)

Pandrol’s Hand Pump Weld Shear is a compact, self-contained tool for quick and precise removal of excess weld metal. With integrated hydraulics and easy handling, it delivers consistent results in under a minute.

Hand Pump Weld Shear (05000)

Pandrol’s Hydraulic Tamper offers powerful, multi-purpose performance with low hand-arm vibration. Engineered for operator safety and comfort, it’s ideal for daily rail maintenance operations.

Tamper (08200)

The Pandrol 04500D and 04525 combine drilling and fastening into compact, ergonomic hydraulic tools for rail maintenance. Their lightweight design ensures mobility, while their robust performance meets heavy-duty demands in any field environment.

Half inch Hydraulic Drill and Impact Wrench (04500D-04525)

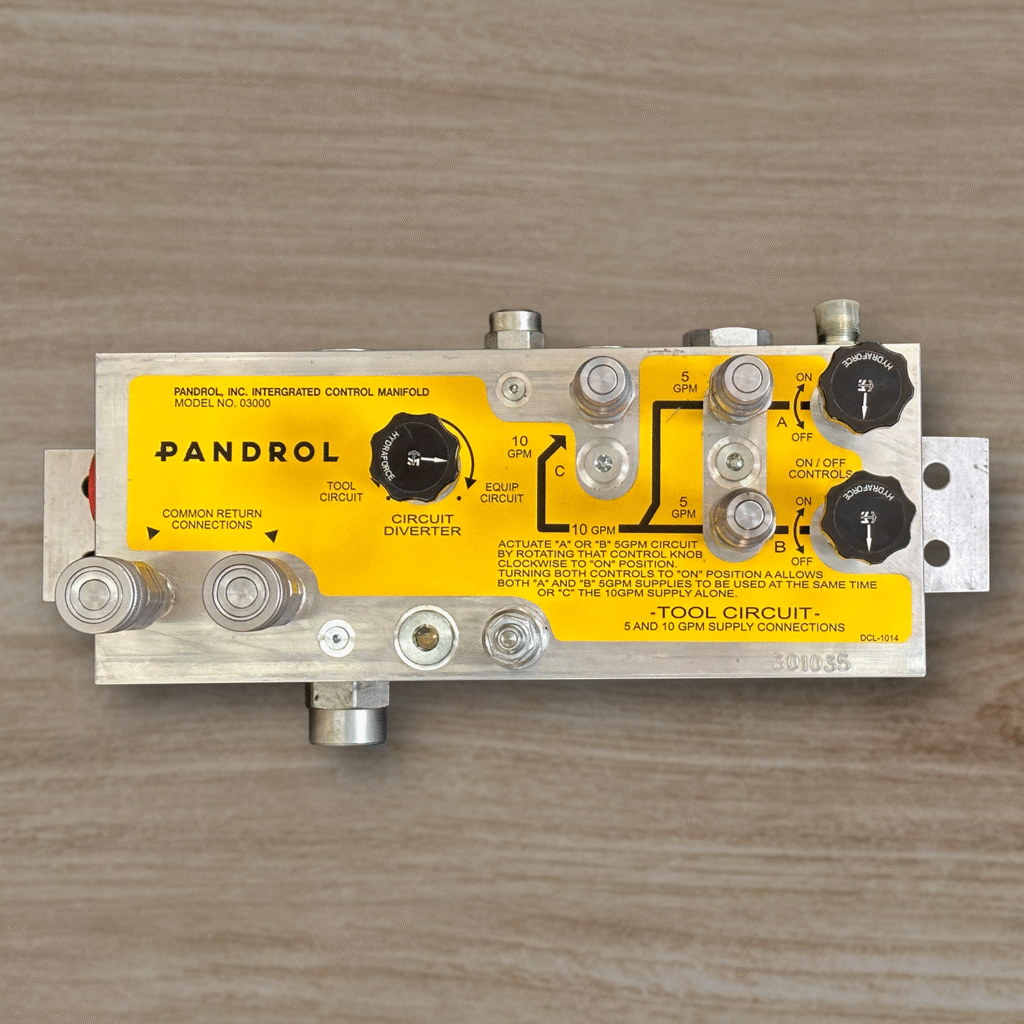

The Pandrol Hydraulic Manifold Circuit (03000) enables safe, efficient use of hydraulic tools by converting flow and pressure from existing systems. Its compact and easy-to-install design makes it a practical solution for enhancing on-site tool capabilities.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

The revolutionary i+align automatic aligner has been designed to transform rail welding through precise, automated rail alignment.

i+align

The Pandrol Lightweight Two-Stage Spike Puller (01100RM) is a portable hydraulic tool delivering 13,000 lbs of pulling force while remaining lightweight at 39 lbs. Its dual-speed system ensures smooth, controlled spike removal.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6” Cup Stone Grinder is built for precision grinding on rail and frogs, combining safety, control, and ease of use. Its compact design and tool-free adjustments make it ideal for fast, efficient maintenance on site.