Rail drilling machine overview

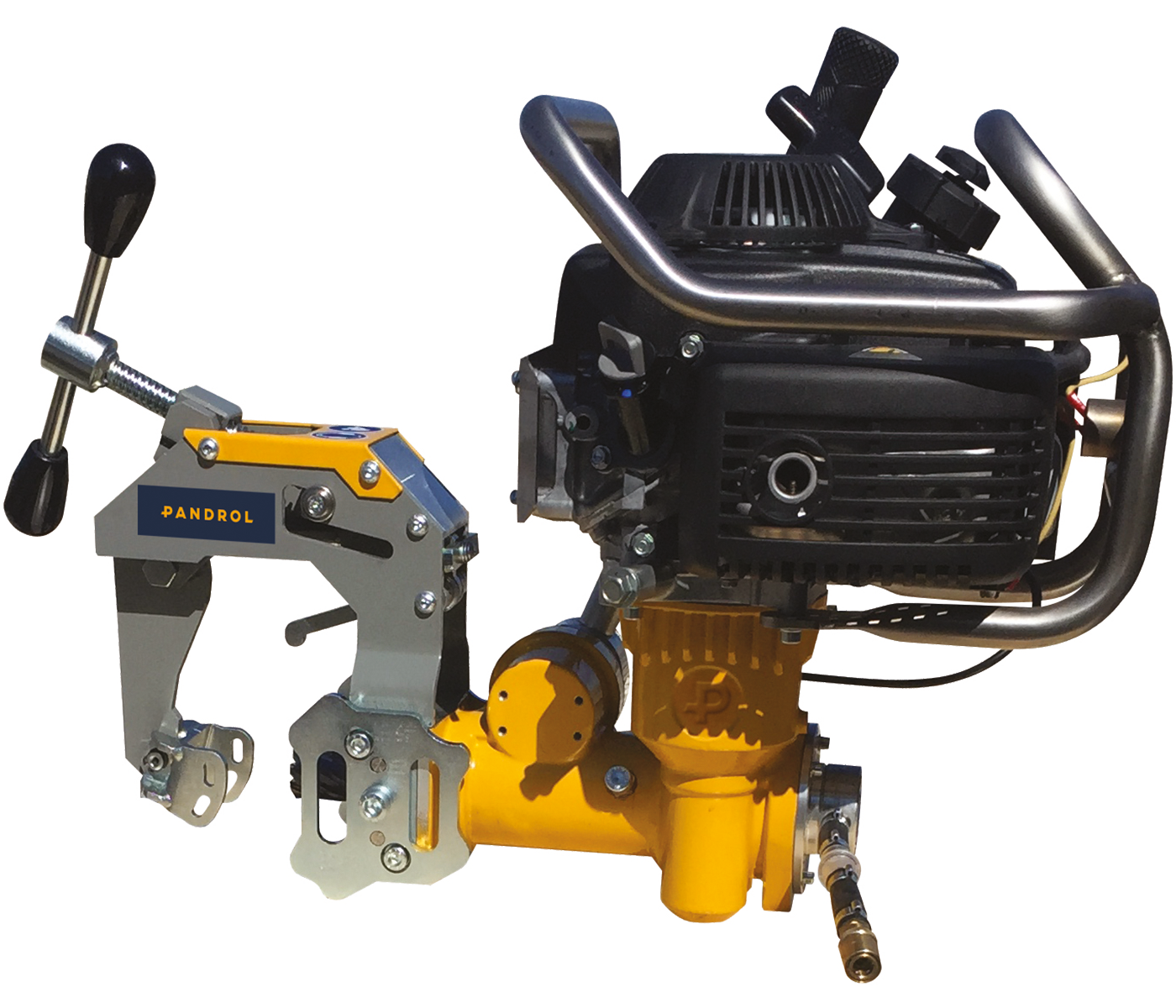

The Pandrol Rail Drilling Machine is designed to bore all kinds of vignole and tram rails with extreme precision. Mounted on a clamp and provided with drilling templates, the drill can be adjusted to the full range of standard drilling patterns.

- Reliable Honda engine with minimal maintenance required

- Modular rail clamp for flexibility and cost savings

- Precision-engineered templates for accurate drilling

- Easy to operate with minimal training required

Downloads

Benefits of the Rail Drilling Machine

Precise Drilling

The machine is designed to bore all types of vignole and tram rails with extreme precision, ensuring high-quality results.

Powerful Engine

The four-stroke Honda engine delivers a maximum power of 1.5 kW at 4,800 rpm, providing reliable and efficient performance.

Accelerator Synchronization

The engine speed is synchronized with the drill’s position, automatically accelerating during drilling to prevent excessive fuel consumption.

Modular Rail Clamp

The modular design allows customers to swap the working rail or drill different patterns by changing the templates on the original clamp.

Ease of Use

The machine’s robust transmission and high-quality drill ensure that operators can drill without excessive force, reducing fatigue.

Technical Features of the Rail Drilling Machine

Components

The machine includes a cooling tank, Honda engine, rail clamp, drilling template, and rail template.

Precise Templates

The templates are produced with precision on a numerically controlled machine, guaranteeing high-quality results with no need for rectification.

Efficient Drill

The high-quality drill is quick and efficient, saving time on drilling operations.

Robust Transmission

The robust transmission, coupled with the high-quality drill, allows operators to work with minimal effort.

Environmentally Friendly

The fuel-efficient engine and accelerator synchronization make the machine more environmentally friendly and cost-effective to operate.

Minimal Maintenance

The reliable Honda engine requires minimal preventive and corrective maintenance, saving customers time and money.

Related product

The shearing process takes place after mould release.

Battery-Operated Weld Shear EMB1/EMB2/EMB2 RAG

It is used during maintenance works to stretch long welded rails before aluminothermic welding and to secure the tensioned rail while cutting. It is capable of joining and maintaining a constant gap between the two rail ends.

Rail Stressor TR75

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The HFP 36V is a battery-powered and fully automated preheater designed for easier and more reliable operation. Its ignition, timing, and stop functions require no manual interference or flame adjustment, making it a highly efficient tool.

High Flow Preheater 36V

i+seal moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.