Straight Stone Grinders (04600-04650-04700-04750)

Pandrol Straight Stone Grinders are powerful, safe tools designed for a wide range of rail grinding applications, including field welds, frogs, and switch points. Available in four models – clockwise rotation (04600), clockwise rotation with trigger (04650), counterclockwise rotation (04700), and counterclockwise rotation with trigger (04750) – these grinders cater to various operational needs.

The models without a trigger feature an on-off valve for control. All models are housed in high-strength aluminum with rigid handles, enhancing both durability and operator safety.

Straight Stone Grinders (04600, 04650, 04700, 04750) product overview

Pandrol Straight Stone Grinders are powerful, safe grinding tools that can be used in a wide range of applications on rail, including field welds, frogs and switch points.

- Four models are available – clockwise rotation (04600), clockwise rotation with trigger (04650), counter-clockwise rotation (04700), and counter-clockwise rotation with trigger (04750).

- The models without a trigger have an on-off valve.

- All come in a high-strength aluminium housing with rigid handles, enhancing operator safety.

Downloads

Advantages of using Straight Stone Grinders

Bespoke grinding

The range of Straight Stone Grinders allow for clockwise or counter-clockwise grinding, with an on/off valve or safety trigger.

Precise tools

The grinders are powerful for their size, enabling efficient, precise grinding on rail.

Versatile design

One tool can be used for a range of applications, including field welds, frogs and switch points.

Long life

The grinders are extremely robust, with a strong aluminium housing and rub pads that extend their life and reduce cost.

Reduced maintenance

Sealed bearings reduce the need for maintenance.

Ergonomic features

The Straight Stone Grinders have rigid handles, heat isolation from hand holds, and are both light weight and compact in size.

Technical features of Straight Stone Grinders

Powerful flow

All of the Straight Stone Grinders operate at 10 gpm (38 lpm), providing the power for strategic grinding in all parts of the rail.

Clockwise and counter-clockwise

The grinders are available with either clockwise rotation (models 04600 and 04650) or counter-clockwise rotation (models 04700 and 04750).

On/off valve or safety trigger

The grinders are available with either an on/off valve (models 04600 and 04650) or an engineered safety trigger (models 04700 and 04750).

Ergonomic handle design

The Straight Stone Grinders have strong, rigid handles that are isolated from hydraulic hoses to protect operators’ hands from the heat of the hydraulic flow.

Rub pads

Rub pads are fitted to either side of the stone guard, decreasing wear when grinding the ball of rail.

Sealed bearings

The tools’ sealed bearings are robust and protected from dirt.

Specifications

Accessories

Related products

Robust and efficient hydraulic power unit designed to operate rail tools in all working conditions.

Diesel Powered Unit 10/5GPM (02900A)

Self-contained hydraulic weld shear designed for fast, clean, and safe weld metal removal.

Hand Pump Weld Shear (05000)

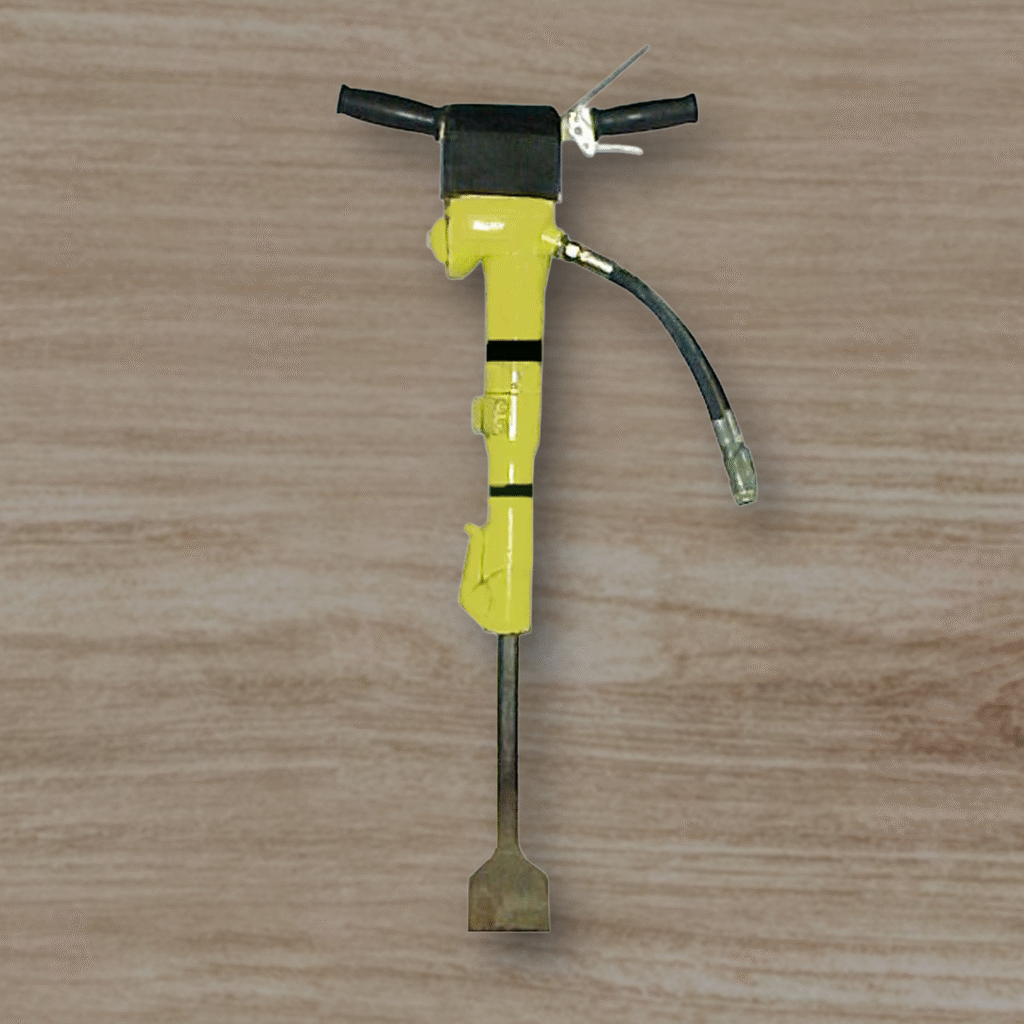

With 5 GPM flow and 2000 PSI pressure, the 08200 model delivers powerful performance for multiple applications, including tamping ballast, cutting asphalt, or breaking concrete. Its ergonomic structure and ease of use make it a valuable asset for any rail maintenance team.

Tamper (08200)

The Half Inch Hydraulic Drill and Impact Wrench (04500D / 04525) is a compact and powerful tool designed for rail maintenance.

Half inch Hydraulic Drill and Impact Wrench (04500-04525)

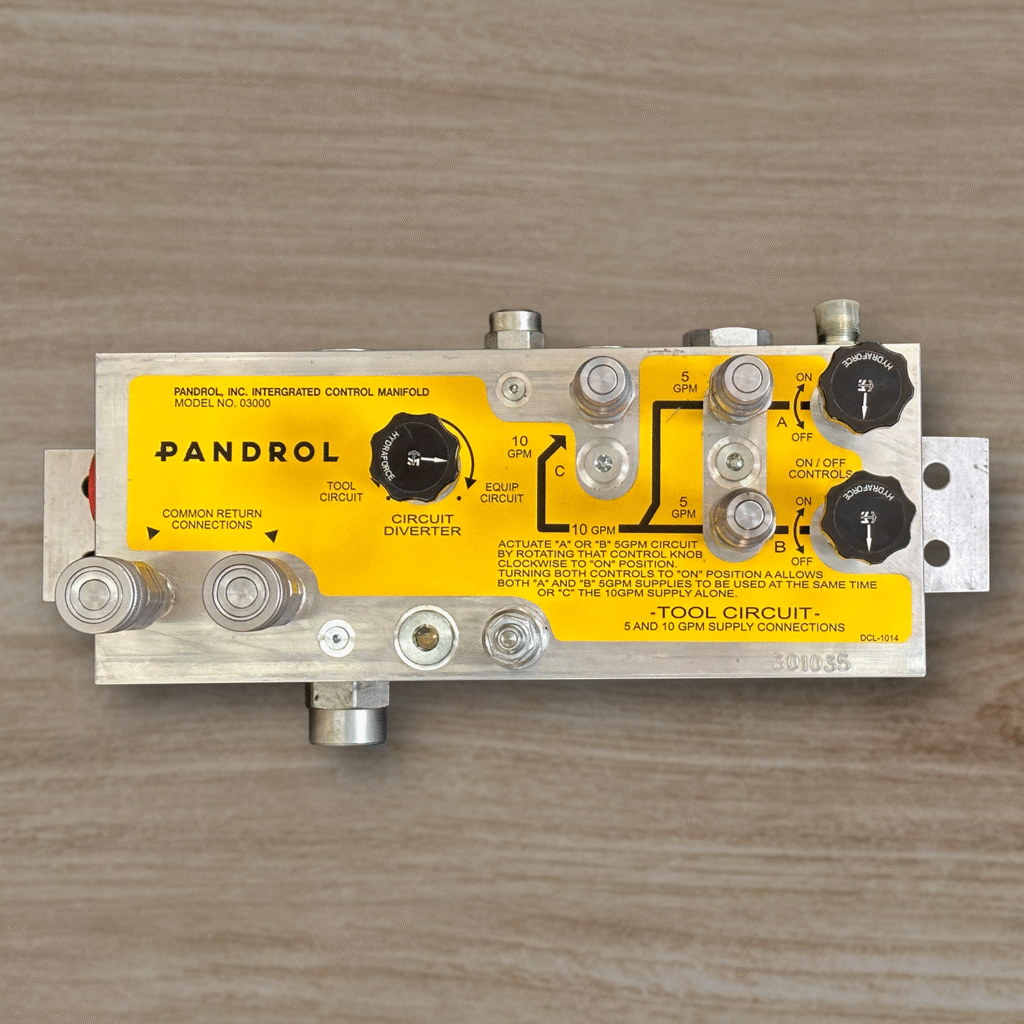

The Hydraulic Manifold Circuit is a self-contained flow and directional control assembly. Compact and easy to install, this manifold provides a safe and cost-effective way of adding hydraulic tool capabilities to your existing range of equipment.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

A powerful spike puller for rail maintenance.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6″ Cup Stone Grinder is a versatile tool designed for grinding the tops of frogs and the rail.

6 inch Cup Stone Grinder (04800-04850)

The Pandrol Surfacing Guide is a rugged but lightweight grinding attachment designed specifically for grinding the top of the rail.

Surfacing Guide Grinder (00700-00700C)

Pandrol’s Profile Grinder (06000B) is a lightweight, precision grinding machine designed specifically for the finish grinding of field welds.

Profile Grinder (06000B)

Pandrol’s Dual Circuit Power Unit (00100K) is a freestanding, easy-to-transport hydraulic power unit.