Fastening Installation Equipment

Pandrol develops and manufactures a wide range of modern clipping equipment which drives efficient construction and maintenance of rail infrastructure. Pandrol clipping machinery adds value to tasks from track renewals and installation to welding and tie change operations.

Streamlining track build and maintenance, one clip at a time

Pandrol’s range of fastening equipment is used to automate the clipping and de-clipping of fastenings, making installation speeds significantly faster than when using hand tools.

- We offer a range of models in different sizes and clipping capabilities to suit various use cases, whether it be small maintenance runs or clipping long stretches of track.

- Our clipping machines are compatible with a variety of different fastening types including Pandrol’s own Fastclip and e-Clip.

- All Pandrol machines are built with the user in mind, featuring intuitive control systems and a variety of safety features.

Downloads

Our products

Compact and lightweight, it is suitable for use by a single operator and can be easily carried onto site.

Clip Driver CD100

The Clip Driver CD100 B clipping machine is designed for clipping and declipping Pandrol Fastclips. Compact and lightweight, it is suitable for use by a single operator and can be easily carried onto site.

Clip Driver CD100 B

The modular, lightweight design of the CD200 IQ enables it to be lifted on and off track easily. Thanks to mechanical and hydraulic quick connectors, it is simple to change between the two clipping tools for Fastclip and e-Clip.

Clip Driver CD200 IQ

Clip Driver CD300 IQ EC is a version specially designed for e-Clip fastening system. The machine’s design is based on the proven technology of Pandrol’s Clip Driver CD400, with enhancements adding to its performance.

Clip Driver CD300 IQ/CD300 EC

When fitted with proximity sensors, the CD400 fastens clips automatically, enabling additional productivity and security.

Clip Driver CD400

This robust and reliable self-propelled machine now has an EU Stage 5 diesel engine from Hatz and a new intelligent control system. The machine installs 4 clips simultaneously across two rails and has a sleeper lift function for new construction projects.

Clip Driver CD400SP IQ

Why buy from Pandrol?

Whether it be track maintenance, installing new track, or working with long stretches of track, we offer machines in a variety of sizes and clipping capabilities to suit your needs.

Designed in our Centre of Engineering Excellence in Sweden, Pandrol clipping machines are built to one global standard by a team of experts who specialise in rail equipment innovation.

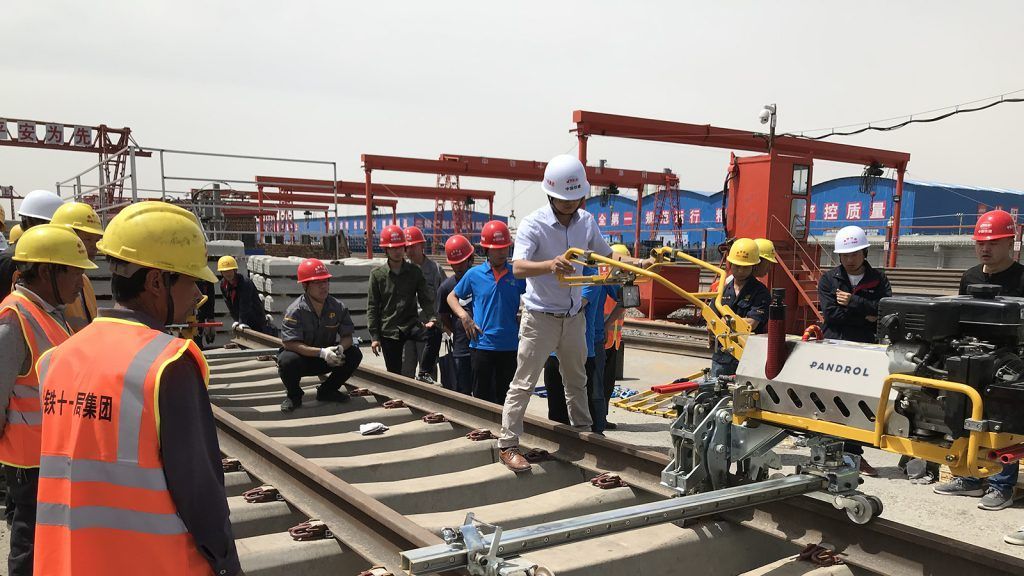

Pandrol offers commissioning and training of operators to ensure our customers get the most value possible from our equipment. Our global teams are available at customers’ disposal throughout the entire buying process.

Pandrol’s equipment for mechanising the clipping & un-clipping of rail fastenings help our customers to keep people off track as much as possible whilst improving the safety standards for those needed to operate the machinery.

The largest machines in Pandrol’s range can clip and unclip 4 clips simultaneously, reaching speeds of up to 40 ties per minute.

The advantages of fastening installation equipment for railway construction and maintenance

Pandrol’s range of fastening installation equipment is engineered to help railway operators and infrastructure companies complete their projects on time and on budget. With over 100 years of experience in the industry, Pandrol knows what works and what doesn’t when it comes to rail construction

Our machines are built for long-term use, with durability in mind from their initial design phases all the way through to production. That means you’ll get a better machine at an affordable price without sacrificing quality or performance.

- Highest quality value-engineered machinery: Pandrol tested and certified fastening installation equipment has earned the trust of railway companies around the world because it is versatile, durable, reliable and cost-effective.

- Maximised efficiency: With Pandrol’s on-track machinery you can maximise the efficiency of projects while reducing costs – our fastening installation equipment is ready to go to work for you.

- Enhanced safety: Pandrol fastening installation equipment mitigates the risk to workers by removing the need for hand tools and also reducing the amount of people needed on track for clipping and unclipping operations.

- Emission free clipping in tunnels: Our smaller battery clipping machine, the CD100 B, is ideal for track operations where maintenance is happening in tunnels or underground, emitting zero emissions whilst clipping fast and effectively.

- Smart clipping: Our brand-new range of iQ clipping machines use intelligent control systems to simplify operation. The new smart system can provide information on the number of clips installed and number of operating hours, whilst also preventing incorrect use of the machine.