Precision Frog Grinder (09200A) product overview

Pandrol’s Precision Frog Grinder (09200A) is a hydraulic-powered, track-mounted machine that brings detailed, four-axis grinding to the field.

- The grinder has a precision guide frame with multiple axis adjustment, enabling the operator to make consistent refinishing grinds.

- In addition, the tool can be used to blend SSC defects on the rail.

Downloads

Advantages of using the Precision Frog Grinder

Accurate four-axis grinding

With accurate four-axis grinding, Pandrol’s Precision Frog Grinder ensures precise, repeatable results, no matter the operator’s skills and experience.

Easy setup

The grinder’s simple, two-part design allows for quick set-up and clearing, saving on track time.

Flexible grinding

The flexibility to change from a straight stone to a cup stone allows the operator to use one tool for grinding a complete maintenance program, including grinding out frog defects, blending out SSC and reprofiling frogs.

8’ base rails

The grinder’s versatility is enhanced by the availability of 8’ base rails for blending out surface defects over greater distances than the standard 4’ base rails allow.

Safe to use

Vibration and dust isolation contribute to safe working conditions and practices.

Easy to transport

The Precision Frog Grinder is compact in size, making it easy to transport and store.

Technical features of the Precision Frog Grinder

Precise engineered movement

The Precision Frog Grinder has been designed to allow for accurate, repeatable movement in any of the four axes.

Adjustable stone

The height and position of the stone can be adjusted within the base frame. In addition, the angle of the stone can be regulated for precise elevations and reprofiling.

Articulating base frame

The base frame can be fully adjusted and locked to the angle of any frog, using an easy reference line and precision adjustment.

Vibration and dust isolation

All vibration and grinding dust created while working on frogs is isolated from the operator.

Multiple grinding stones

The Precision Frog Grinder can be used with a straight stone for flange ways and rail sides, and a cup stone for precise grinding of the tops and sides of rails.

Compact size

The grinder and its base are compact in size, easing transportation and storage.

Specifications

Accessories

Related products

Robust and efficient hydraulic power unit designed to operate rail tools in all working conditions.

Diesel Powered Unit 10/5GPM (02900A)

Self-contained hydraulic weld shear designed for fast, clean, and safe weld metal removal.

Hand Pump Weld Shear (05000)

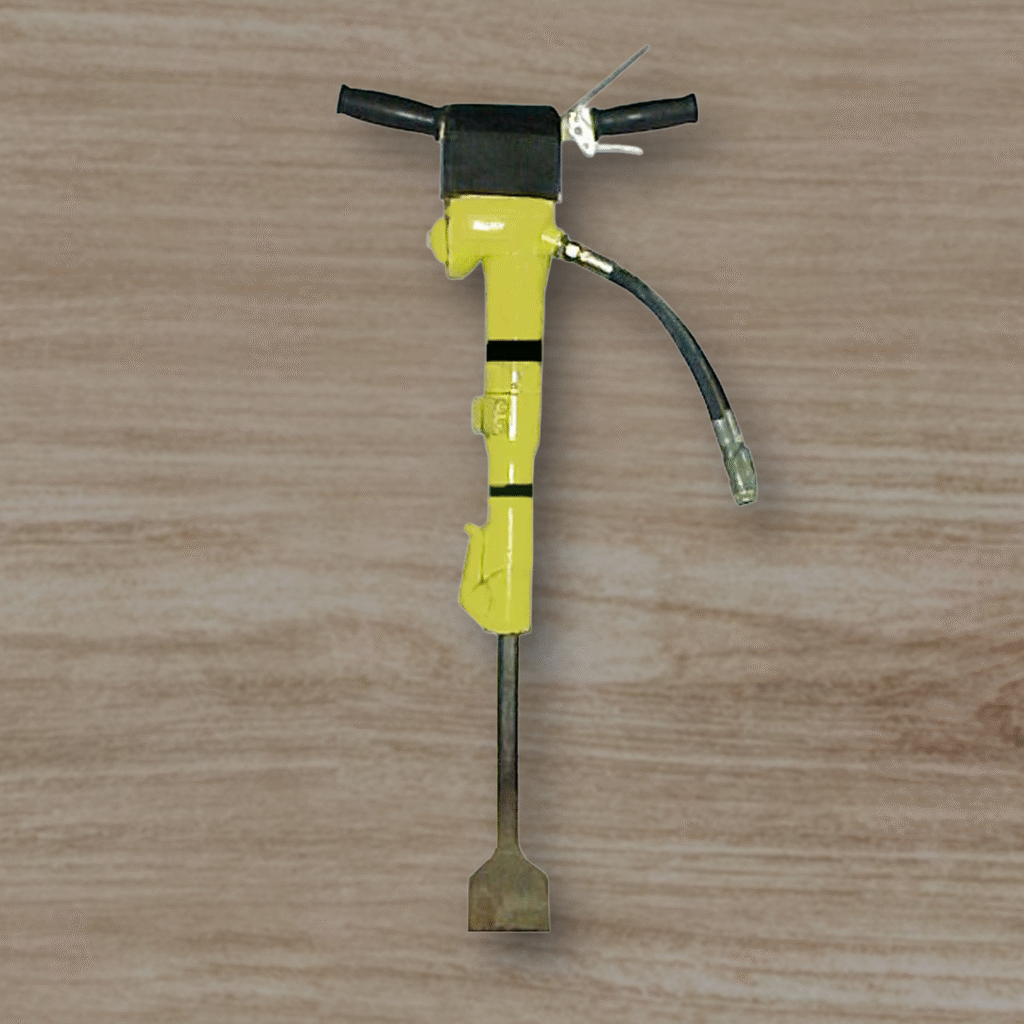

With 5 GPM flow and 2000 PSI pressure, the 08200 model delivers powerful performance for multiple applications, including tamping ballast, cutting asphalt, or breaking concrete. Its ergonomic structure and ease of use make it a valuable asset for any rail maintenance team.

Tamper (08200)

The Half Inch Hydraulic Drill and Impact Wrench (04500D / 04525) is a compact and powerful tool designed for rail maintenance.

Half inch Hydraulic Drill and Impact Wrench (04500-04525)

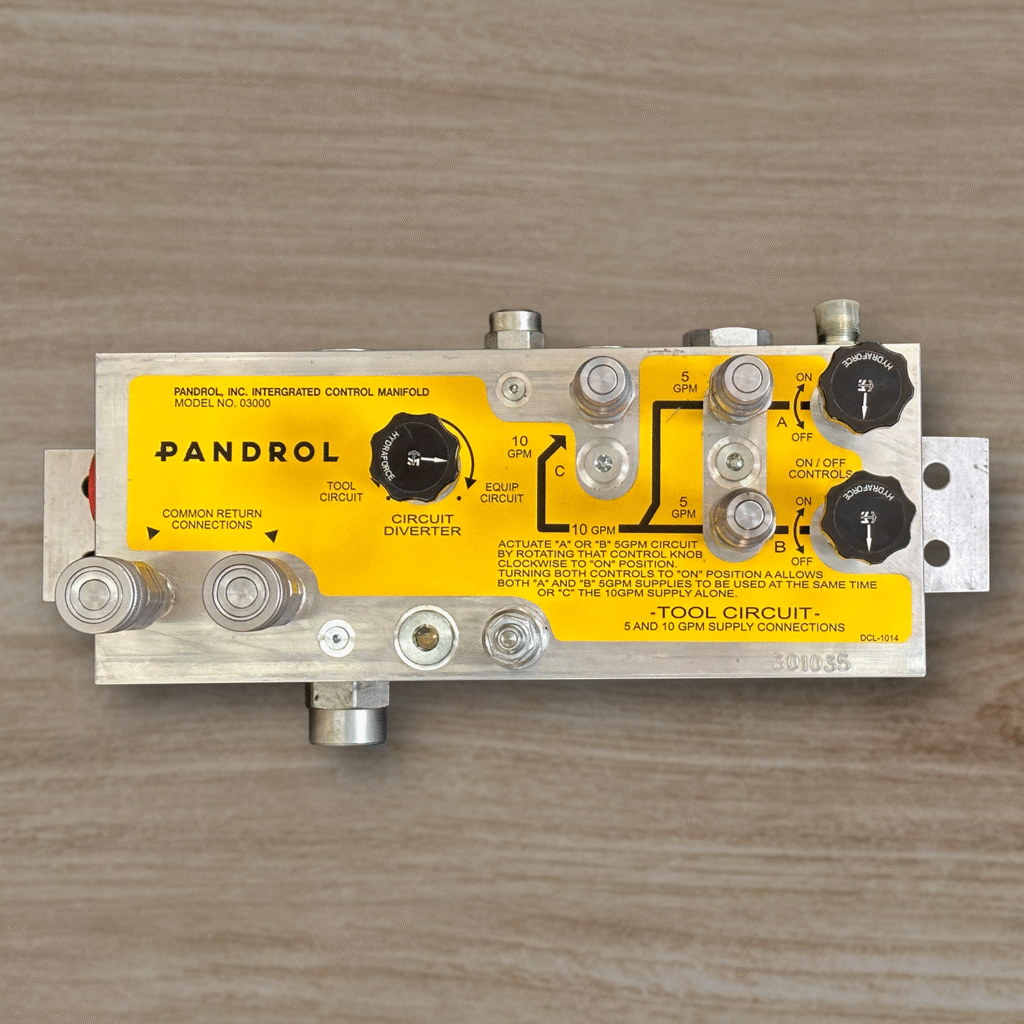

The Hydraulic Manifold Circuit is a self-contained flow and directional control assembly. Compact and easy to install, this manifold provides a safe and cost-effective way of adding hydraulic tool capabilities to your existing range of equipment.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

A powerful spike puller for rail maintenance.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6″ Cup Stone Grinder is a versatile tool designed for grinding the tops of frogs and the rail.

6 inch Cup Stone Grinder (04800-04850)

The Pandrol Surfacing Guide is a rugged but lightweight grinding attachment designed specifically for grinding the top of the rail.

Surfacing Guide Grinder (00700-00700C)

Pandrol’s Profile Grinder (06000B) is a lightweight, precision grinding machine designed specifically for the finish grinding of field welds.

Profile Grinder (06000B)

Pandrol’s Dual Circuit Power Unit (00100K) is a freestanding, easy-to-transport hydraulic power unit.