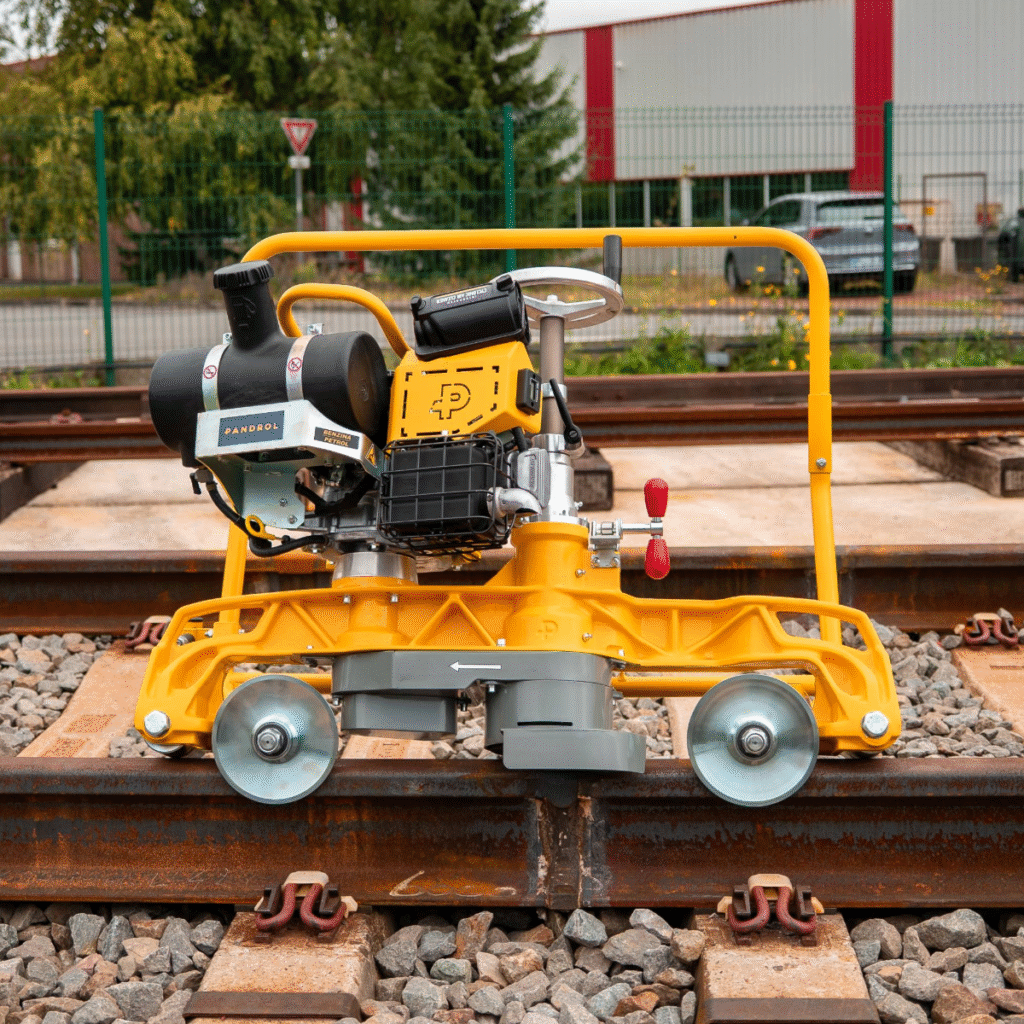

Rail Saw HC305/355/406

Cut rails of all profiles and grades with speed and accuracy with Pandrol’s Rail Saw selection. The ergonomic design of the rail clamps of our HC305, HC355 and HC406 rail saw models prevents physical stress on the rail during sawing – ensuring optimal results.

Pandrol Rail Saws Explained

Power, speed and accuracy are essential when it comes to performing rail cuts in a busy rail environment. Whether you’re conducting essential maintenance and repairs or installing a brand new system, your team need a high-performance Pandrol Rail Saw to get the job done.

Pandrol Rail Saws come complete with a support arm equipped with a tightening jaw which ensures a quick and rigid fixing on the rail, as well as supporting and guiding the saw during use. A built-in cutting guide provides confidence in an accurate cut with each use. The device fixing, reversible on the support arm, enables the saw to be positioned on the inside or the outside of the track without dismantling the tightening jaw. With proper use, these features guarantee a high-quality cut that’s perpendicular to the rail every time.

- Can be positioned inside or outside of the rail by dismantling the tightening jaw

- Cutting guide ensures accurate cuts with each use

- Prevent accidents with the built-in safety device preventing saving operation without the support arm

Downloads

Advantages of the Rail Saw HC305 / HC355 / HC406

Ease of use

Set up and operate the Pandrol Rail Saw quickly and simply. No specialist tools or push or pull effort are required. Just guide the machine along the rail and perform an easy vertical swivelling motion to operate.

Advanced safety

Rely on the enhanced safety features of Pandrol’s Rail Saws. The automatic engine cut-off feature activates when the saw is not attached to the rail support, protecting operators from the risk of accident or injury.

High performance

Speed up operations with the advanced speed of Pandrol Rail Saws. Our Rail Saw models are fast and efficient compared to alternative portable cutting tools thanks to their powerful engines and high-power transmission rate.

Accuracy

Guarantee high-quality cutting that is perfectly perpendicular to the rail thanks to the Pandrol Rail Saw’s built-in support arm, which guides the saw. Along with the cutting guide, its monobloc aluminium construction provides unrivalled accuracy and repeatability.

Versatility

Cut any type and size of rail thanks to the versatile capabilities of Pandrol’s Rail Saw models. Choose the version that suits your rail project and system, whether your cutting requirement is for vignole rail, crane rail, grooved rail, or any type of special rail.

Technical features of the Rail Saw HC305 / HC355 / HC406

Unique design

Position the support arm on either the inside or outside of the track without dismantling the tightening jaw thanks to the saw’s reversible capabilities. Unlike other rail saw designs, all the weight of the Pandrol Rail Saw is carried by the rail support. The tightening jaw ensures rigid fixing on the rail.

Motorisation

Pandrol’s Rail Saw is highly motorised compared to alternative models on the market. Ensure a high-power transmission rate thanks to the Pandrol Rail Saw’s Poly-V Belt 4PK, the most powerful gas engine in the rail portable cutting tool industry.

Safety features

Provide your operators with protection against hot exhaust fumes and sparks with the safety features built into the design of Pandrol’s Rail Saws. An electrical shunt controls the opening of the engine ignition circuit and its automatic closure when the rail saw is disconnected from the support arm.

Filtration

Choose a Rail Saw designed specifically for the tough railway environment. In addition to quick and easy installation by hand screwing, Pandrol Rail Saws comes with three-step air filtration and air injection.

Related products

The Pandrol SolidGrinder-P-150-VIR has been designed to fully grind the rail head after welding. Like all of Pandrol’s grinding machines, it combines power and reliability with ease of use.

SolidGrinder-P-150-VIR

The Pandrol Frog/Profile Grinder delivers accurate rail and frog grinding with ergonomic roll-over control. Its lightweight frame and optional outrigger make it a flexible solution for precise weld finishing in the field.

Frog Profile Grinder (05900-05950)

The Pandrol Diesel Powered Unit (02900A) provides reliable hydraulic output of 5 or 10 GPM for powering rail tools. Equipped with a robust 18 hp Kubota engine, it ensures dependable performance even in tough environments.

Diesel Powered Unit 10/5GPM (02900A)

Pandrol’s Hand Pump Weld Shear is a compact, self-contained tool for quick and precise removal of excess weld metal. With integrated hydraulics and easy handling, it delivers consistent results in under a minute.

Hand Pump Weld Shear (05000)

Pandrol’s Hydraulic Tamper offers powerful, multi-purpose performance with low hand-arm vibration. Engineered for operator safety and comfort, it’s ideal for daily rail maintenance operations.

Tamper (08200)

The Pandrol 04500D and 04525 combine drilling and fastening into compact, ergonomic hydraulic tools for rail maintenance. Their lightweight design ensures mobility, while their robust performance meets heavy-duty demands in any field environment.

Half inch Hydraulic Drill and Impact Wrench (04500D-04525)

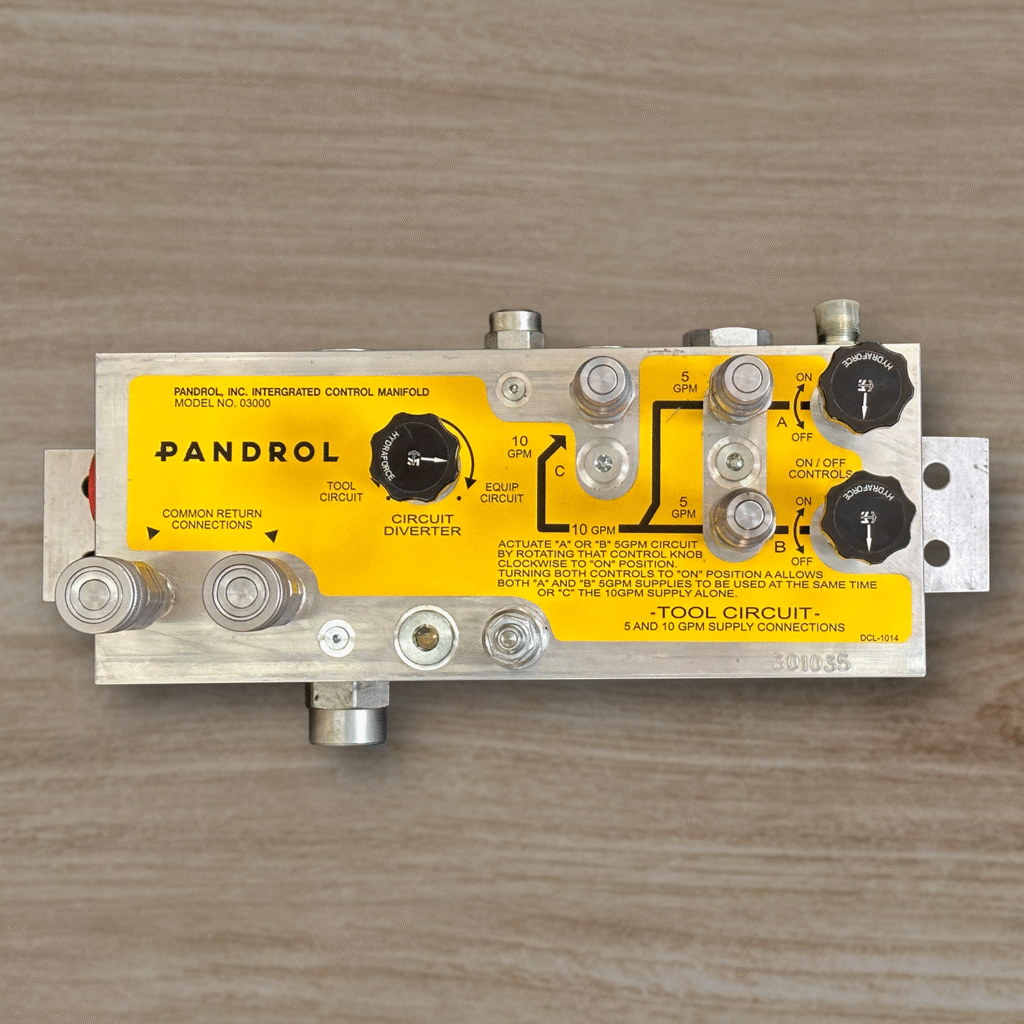

The Pandrol Hydraulic Manifold Circuit (03000) enables safe, efficient use of hydraulic tools by converting flow and pressure from existing systems. Its compact and easy-to-install design makes it a practical solution for enhancing on-site tool capabilities.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

The revolutionary i+align automatic aligner has been designed to transform rail welding through precise, automated rail alignment.

i+align

The Pandrol Lightweight Two-Stage Spike Puller (01100RM) is a portable hydraulic tool delivering 13,000 lbs of pulling force while remaining lightweight at 39 lbs. Its dual-speed system ensures smooth, controlled spike removal.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6” Cup Stone Grinder is built for precision grinding on rail and frogs, combining safety, control, and ease of use. Its compact design and tool-free adjustments make it ideal for fast, efficient maintenance on site.