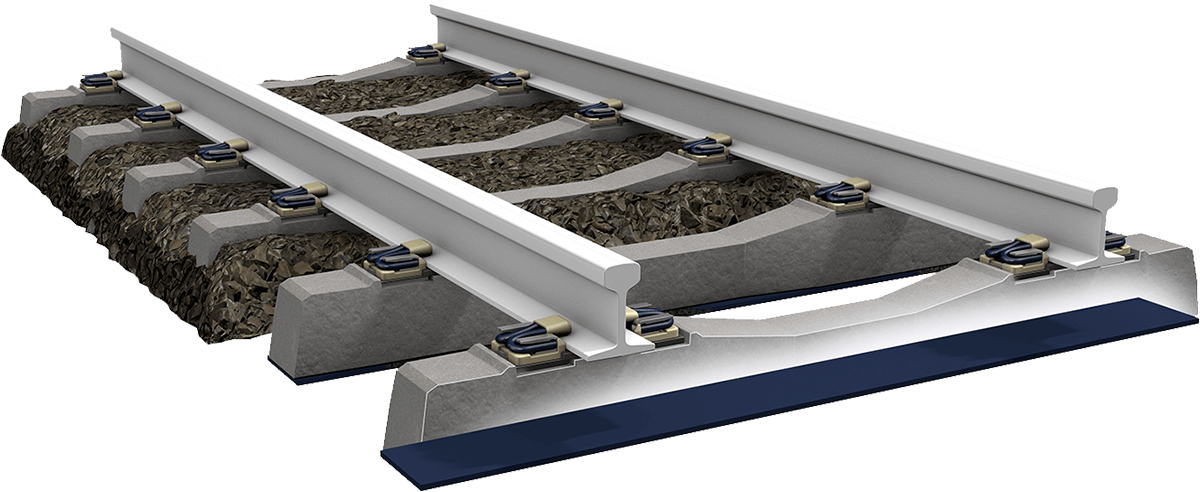

Under-Sleeper Pads product overview

The systems are easy to install, maintenance free and compatible with all types of track design; with their use also proven to reduce the life-cycle cost of the railway.

When USPs are installed, the stress within each sleeper is reduced due to a more even distribution of axle load.

- Contact area between the ballast and sleeper is also increased, resulting in a more homogeneous track quality.

- USPs are made from high-quality resin-bonded rubbers. Depending on the project, the design parameters can be adjusted to achieve a vibration attenuation target whilst also ensuring track quality.

- Across all ballasted track scenarios, designed to improve track quality, give better load distribution and provide vibration reduction, constructed from high-quality materials and resistant to any prevailing conditions.

Downloads

Advantages of using Under-Sleeper Pads

Reducing maintenance

Installation of Under Sleeper Pads can extend the interval between essential track maintenance, such as LLT, by a minimum factor two.

Cost saving

The thickness of the ballast layer can be reduced by up to 10cm with the addition of USPs to normalise track stiffness.

Functional and versatile

Including USPs within a transition between sub-structures offers a controlled difference in track stiffness and settlement, resulting in a much smoother transition.

Stiffer ballast matrix

The use of USPs can combat the effect of sand ingress, which stiffens the ballast matrix.

Reduce rail corrugation

USPs can greatly reduce rail corrugation in tight curves, increasing grinding intervals and therefore reducing maintenance costs.

Increased sustainability

USPs have a low environmental impact and increase the sustainability of the track.

Technical features of Under-Sleeper Pads

Designed for fast and simple installation

Under Sleeper Pads can either be installed onto fresh concrete during sleeper production using MFF® technology, or glued onto existing sleepers.

Extended lifespan

Designed to last, Pandrol USPs have tested long-term stable properties and continued performance. They are highlyresistant to changing atmospheric conditions, chemical exposure and mechanical fatigue.

Vibration attenuation

Available in a wide range of stiffnesses, Pandrol USPs provide a tuneable approach to vibration isolation that can be modified to meet exact requirements.

Tailor-made solutions

Pandrol USPs are individually designed for the required sleeper profile, meaning that a perfect fit is always achieved.

High resilience

The Resin-Bonded-Rubber used in Pandrol USPs is highly resilient and returns to its original form even after large localised indentation; such as when stacking Sleepers with USPs on thin wooden blocks.

Sustainability

Pandrol USPs are made from over 90% recycled materials and are 100% recyclable.

Specifications

Reference Sectors

CATEGORY APPROVALS

- Light Rail

- High Speed

- Mainline

- Metro

Related products

Pandrol receives world first CO2-neutral label for under sleeper pad

No sistema FTrack da Pandrol, o trilho é fixado por fixações de trilho com suporte discreto e integrado pelo FT ENCAPSULATION – perfis resilientes de preenchimento da rede de trilhos

FTrack da Pandrol

Mantas sob lastro

Reduz a transmissão de vibração do material rodante para as estruturas circundantes, garantindo o controle do fluxo elétrico para fora dos trilhos.

QTrack®

Fácil de instalar, livre de manutenção e compatível com todos os tipos de trilhos e sistemas de trilhos, ela foi concebida para reduzir os custos do ciclo de vida da ferrovia.