Impact Wrench (02500) product overview

The 1” wrench is safe and efficient to use, with an anti-vibration design and an optional handle to provide the optimum work position for the task at hand.

- A torque adjustment knob ‘dials in’ torque from 0–3500 ft lb. Heavy-duty impacting mechanisms ensure consistent power.

Downloads

Benefits of the Impact Wrench (02500)

Ergonomically efficient

The Impact Wrench’s anti-vibration design makes it an ergonomically efficient, safe choice for operators.

Enhanced safety

The optional ‘stand-up’ handle increases the tool’s safety and ease of use.

Robust

Robust and strong, the wrench is effective for removing and tightening all types of bolts, including crossing, frog and track.

Powerful

Heavy-duty impacting mechanisms ensure consistent power and increase efficiency.

Versatile

Compatibility with a range of hydraulic systems means that the wrench can be used with different flow outputs, where a number of tools may be required.

Lightweight

The Impact Wrench is lightweight, making it easy to carry and manoeuvre into position on site.

Technical features of the Impact Wrench (02500)

Compatible with multiple hydraulic systems

Pandrol’s Impact Wrench is designed to operate on 5 gpm (19 lpm) or 10 gpm (38 lpm) hydraulic systems.

Torque adjustment

A torque adjustment knob ‘dials in’ torque from 0–3500 ft lb.

Ergonomic design

The wrench’s extended reach means that it can be operated at track level while the trigger and handles are in a comfortable, efficient position for the user. The tool has been designed to have anti-vibration properties.

Lightweight and portable

The wrench weighs just 36 lbs (16 kg), so is easy to move around on site.

Easy maintenance

The wrench’s front impacting assembly can be easily removed and replaced, allowing for continuous work or scheduled maintenance.

Optional handle

When the stand-up handle is installed, the operator can remain standing while working on track bolts.

Related products

With 5 GPM flow and 2000 PSI pressure, the 08200 model delivers powerful performance for multiple applications, including tamping ballast, cutting asphalt, or breaking concrete. Its ergonomic structure and ease of use make it a valuable asset for any rail maintenance team.

Tamper (08200)

The Half Inch Hydraulic Drill and Impact Wrench (04500D / 04525) is a compact and powerful tool designed for rail maintenance.

Half inch Hydraulic Drill and Impact Wrench (04500-04525)

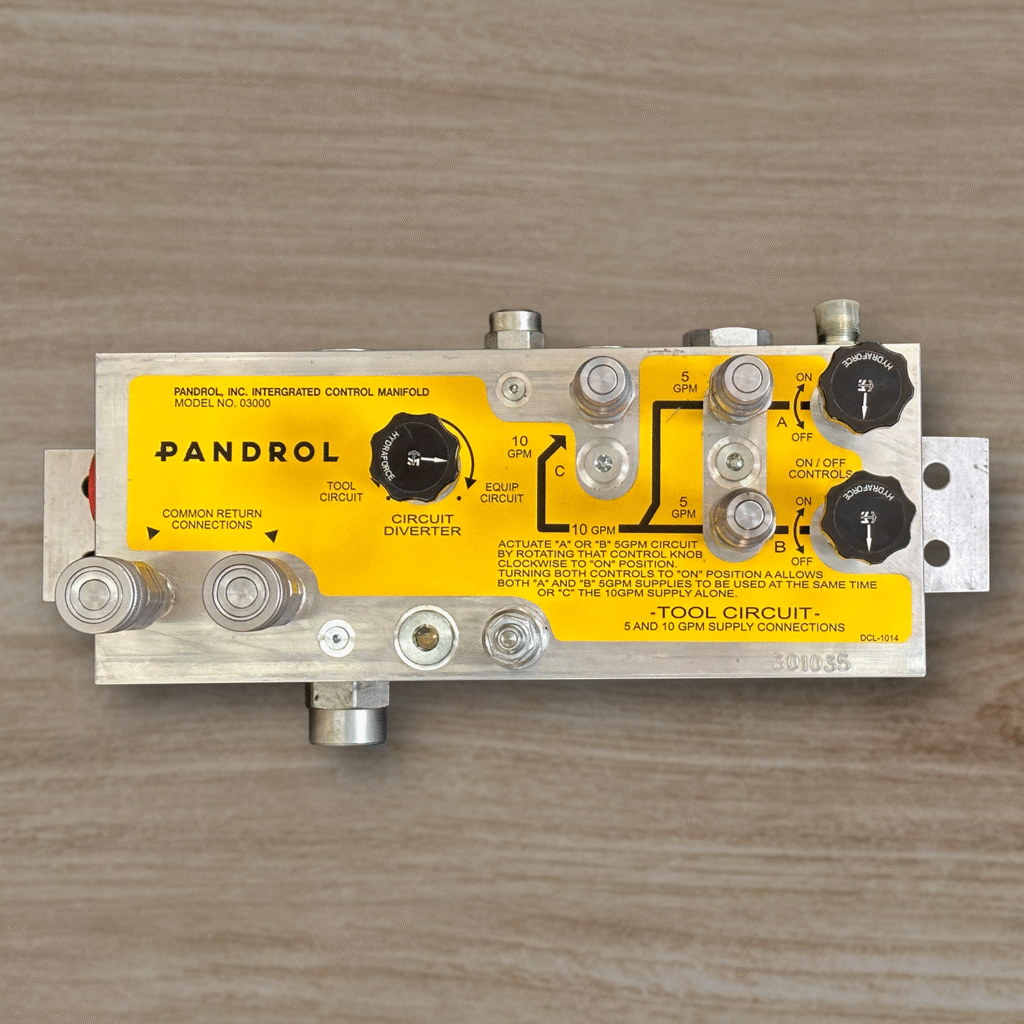

The Hydraulic Manifold Circuit is a self-contained flow and directional control assembly. Compact and easy to install, this manifold provides a safe and cost-effective way of adding hydraulic tool capabilities to your existing range of equipment.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

A powerful spike puller for rail maintenance.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6″ Cup Stone Grinder is a versatile tool designed for grinding the tops of frogs and the rail.

6 inch Cup Stone Grinder (04800-04850)

The Pandrol Surfacing Guide is a rugged but lightweight grinding attachment designed specifically for grinding the top of the rail.

Surfacing Guide Grinder (00700-00700C)

Pandrol’s Profile Grinder (06000B) is a lightweight, precision grinding machine designed specifically for the finish grinding of field welds.

Profile Grinder (06000B)

Pandrol’s Dual Circuit Power Unit (00100K) is a freestanding, easy-to-transport hydraulic power unit.

Dual Circuit Power Unit (00100K)

The equipment can be used for normal gap, wide gap and head wash repair (HWR) welding.

i+cool

With four-axis precision and the ability to use both straight and cup stones, this tool ensures quality grinding in the field.