Multi-Purpose Grinder (06950)

Product overview

Designed for flexibility, this tool allows vertical, horizontal, and angled grinding with minimal vibration. Its compact, user-friendly structure makes it ideal for a wide range of rail maintenance applications.

- Adjustable grinding head and frame rollers support multiple configurations, from field to switch point grinding.

- Anti-vibration design and integrated safety trigger ensure comfortable and secure operation in all conditions.

Downloads

Benefits of Multi-Purpose Grinder (06950)

Versatile Grinding Solution

The Multi-Purpose Grinder is extremely versatile, offering a single solution for use across a wide range of grinding applications.

Ergonomic Design for Operator Comfort

The grinder’s ergonomic design enables operators to remain upright while grinding and to adjust the tool’s height and angle for safe, comfortable working.

Built-In Safety Features

Safety features, including a lock on the actuation trigger and flow control to prevent the grinding stone over-speeding, make the Multi-Purpose Grinder a particularly safe choice for grinding operations.

Vibration Isolation for Operator Comfort

Vibration – often an issue for operators when grinding – is avoided as the grinder is isolated from its handles.

Lightweight and Portable

Lightweight and compact, the Multi-Purpose Grinder is easy to store and transport.

Technical features of Multi-Purpose Grinder (06950)

Adjustable grinding head and rail guide

The position of the grinding head and rail guide can be adjusted to allow for different tasks, including grinding vertically, horizontally and at a 45-degree angle to the rail.

Adjustable frame rollers

Adjustable frame rollers on the front of the tool keep it in position while performing a range of grinding applications, including switch grinding, frog grinding and profile grinding.

Adjustable handle

The grinder’s adjustable rear handle allows the operator to adjust the tool to the optimum height and angle.

Anti-vibration

The grinder is isolated away from the tool’s handles, protecting the operator from vibration during use.

Safety features

A positive lock on the actuation trigger prevents the grinder being started by mistake and the tool incorporates flow control to prevent the grinding stone moving too fast.

Compact storage

The handle can be lowered and swivelled around for compact storage and easy transportation.

Related products

The Pandrol SolidGrinder-P-150-VIR has been designed to fully grind the rail head after welding. Like all of Pandrol’s grinding machines, it combines power and reliability with ease of use.

SolidGrinder-P-150-VIR

The Pandrol Frog/Profile Grinder delivers accurate rail and frog grinding with ergonomic roll-over control. Its lightweight frame and optional outrigger make it a flexible solution for precise weld finishing in the field.

Frog Profile Grinder (05900-05950)

The Pandrol Diesel Powered Unit (02900A) provides reliable hydraulic output of 5 or 10 GPM for powering rail tools. Equipped with a robust 18 hp Kubota engine, it ensures dependable performance even in tough environments.

Diesel Powered Unit 10/5GPM (02900A)

Pandrol’s Hand Pump Weld Shear is a compact, self-contained tool for quick and precise removal of excess weld metal. With integrated hydraulics and easy handling, it delivers consistent results in under a minute.

Hand Pump Weld Shear (05000)

Pandrol’s Hydraulic Tamper offers powerful, multi-purpose performance with low hand-arm vibration. Engineered for operator safety and comfort, it’s ideal for daily rail maintenance operations.

Tamper (08200)

The Pandrol 04500D and 04525 combine drilling and fastening into compact, ergonomic hydraulic tools for rail maintenance. Their lightweight design ensures mobility, while their robust performance meets heavy-duty demands in any field environment.

Half inch Hydraulic Drill and Impact Wrench (04500D-04525)

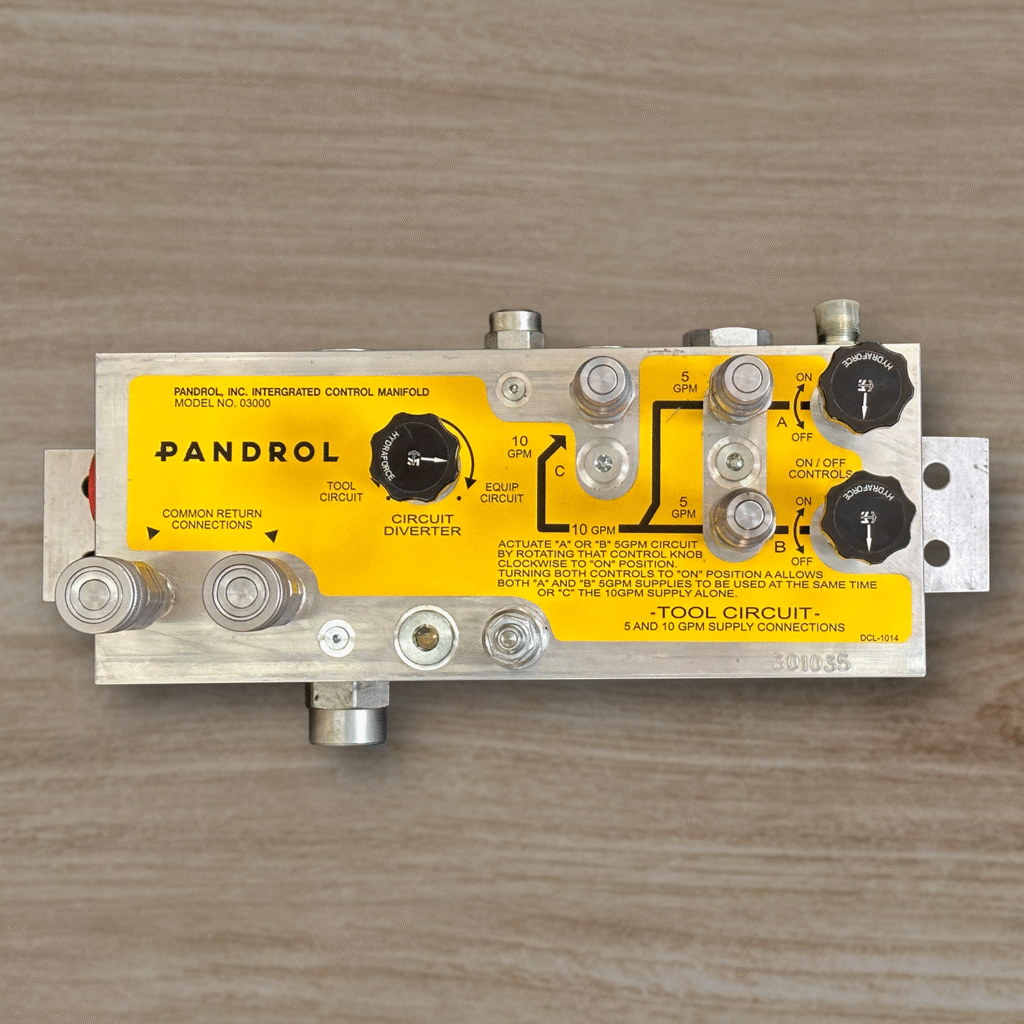

The Pandrol Hydraulic Manifold Circuit (03000) enables safe, efficient use of hydraulic tools by converting flow and pressure from existing systems. Its compact and easy-to-install design makes it a practical solution for enhancing on-site tool capabilities.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

The revolutionary i+align automatic aligner has been designed to transform rail welding through precise, automated rail alignment.

i+align

The Pandrol Lightweight Two-Stage Spike Puller (01100RM) is a portable hydraulic tool delivering 13,000 lbs of pulling force while remaining lightweight at 39 lbs. Its dual-speed system ensures smooth, controlled spike removal.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6” Cup Stone Grinder is built for precision grinding on rail and frogs, combining safety, control, and ease of use. Its compact design and tool-free adjustments make it ideal for fast, efficient maintenance on site.