Reversing Rail Saw (03900A) product overview

Pandrol’s Reversing Rail Saw (03900A) is a hydraulic-powered abrasive rail saw that can cut rail safely from either side. The saw simply needs to be pivoted to the other side of the rail – there is no need for disconnection or realignment.

- Maintenance free, ergonomically designed and safe to use, the Reversing Rail Saw is a cost-effective choice for efficient rail cutting.

- Sparks are safely directed downward, no matter which side of the rail the operator is cutting from.

- The tool’s ability to pivot over the rail to cut from either side allows for the full diameter of the saw blade to be used.

Downloads

Advantages of using the Reversing Rail Saw

Highly efficient

The simple pivot design of the Reversing Rail Saw’s clamp assembly ensures exact alignment of the rail cut, increasing efficiency and saving time.

Safe design

The saw’s high torque design and rpm speed make it a particularly safe choice.

Comfortable cutting

The adjustable height of the clamp arm contributes to users’ comfort and safety while they perform the cutting process.

Redirected sparks

The controlled downward spark path further contributes to operators’ safety while cutting.

Reduced vibrations

Separating the power source from the hydraulic tool reduces vibration and noise.

No exhaust

There is no exhaust or mixing of fuels, as associated with other hydraulic tools.

Technical features of the Reversing Rail Saw

Easy cutting alignment

The saw clamp is designed to allow the operator to pivot and cut from either side of the rail without realignment, using the full saw blade diameter.

Compatibile with 14” and 16” blades

The Reversing Rail Saw can be used safely with either 14” or 16” industry standard diameter saw blades, due to its high torque design and safe rpm speed.

Safe spark control

The saw’s bi-rotational design means that sparks are directed downward while the rail is being cut, no matter which side of the rail the operator is cutting from.

Maintenance free

The saw’s hydraulic motor and drive bearing are sealed, which virtually eliminates engine maintenance and lubrication requirements.

Vibration isolation

The hydraulic motor is isolated from the saw’s handles, so the vibration associated with holding the saw motor is not transmitted to the operator’s hands.

Crane rail clamp option

Pandrol offers an optional crane rail clamp that enables the Reversing Rail Saw to be clamped over large rail profiles as well steel beams.

Specifications

Accessories

Related products

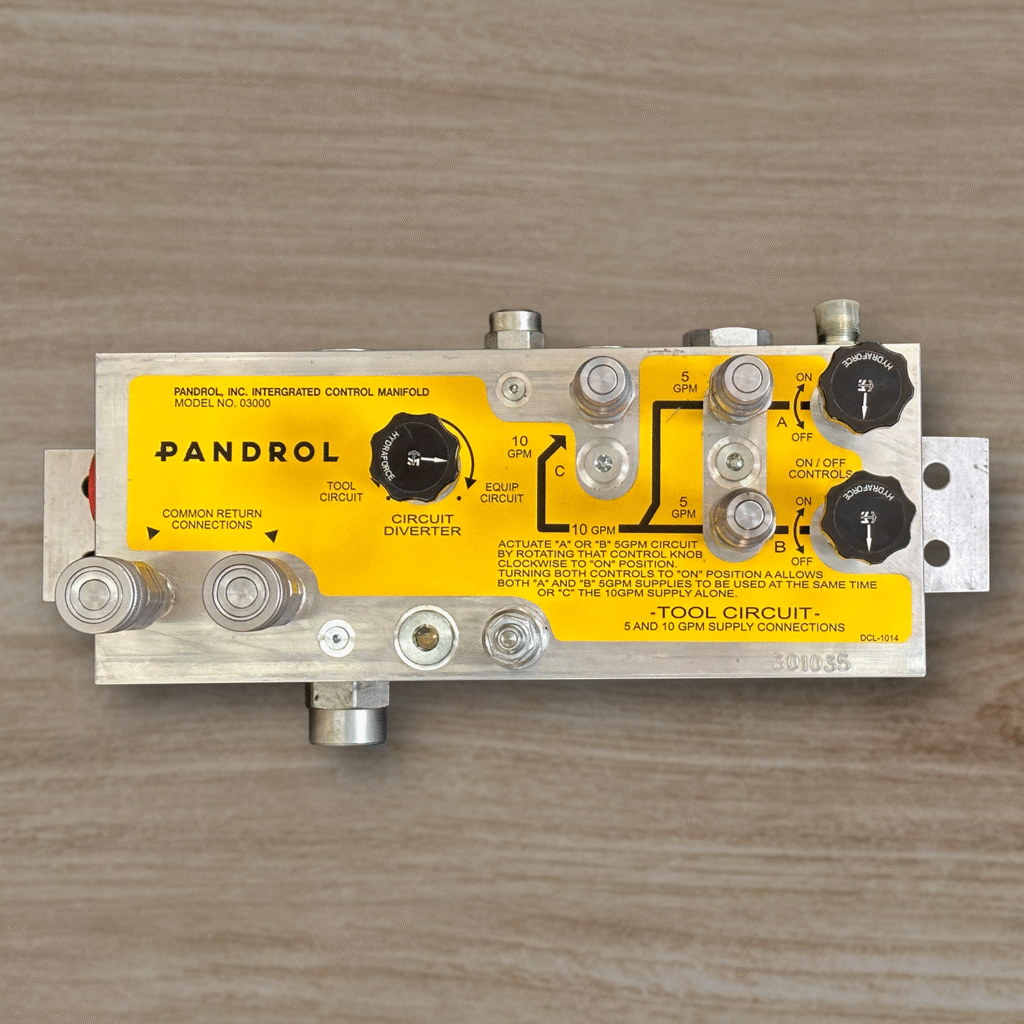

The Hydraulic Manifold Circuit is a self-contained flow and directional control assembly. Compact and easy to install, this manifold provides a safe and cost-effective way of adding hydraulic tool capabilities to your existing range of equipment.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

A powerful spike puller for rail maintenance.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6″ Cup Stone Grinder is a versatile tool designed for grinding the tops of frogs and the rail.

6 inch Cup Stone Grinder (04800-04850)

The Pandrol Surfacing Guide is a rugged but lightweight grinding attachment designed specifically for grinding the top of the rail.

Surfacing Guide Grinder (00700-00700C)

Pandrol’s Profile Grinder (06000B) is a lightweight, precision grinding machine designed specifically for the finish grinding of field welds.

Profile Grinder (06000B)

Pandrol’s Dual Circuit Power Unit (00100K) is a freestanding, easy-to-transport hydraulic power unit.

Dual Circuit Power Unit (00100K)

The equipment can be used for normal gap, wide gap and head wash repair (HWR) welding.

i+cool

The 1” wrench is safe and efficient to use, with an anti-vibration design and an optional handle to provide the optimum work position for the task at hand.

Impact Wrench (02500)

With four-axis precision and the ability to use both straight and cup stones, this tool ensures quality grinding in the field.

Precision Frog Grinder (09200A)

Pandrol Straight Stone Grinders are powerful, safe tools designed for a wide range of rail grinding applications, including field welds, frogs, and switch points. Available in four models – clockwise rotation (04600), clockwise rotation with trigger (04650), counterclockwise rotation (04700), and counterclockwise rotation with trigger (04750) – these grinders cater to various operational needs. The models without a trigger feature an on-off valve for control. All models are housed in high-strength aluminum with rigid handles, enhancing both durability and operator safety.