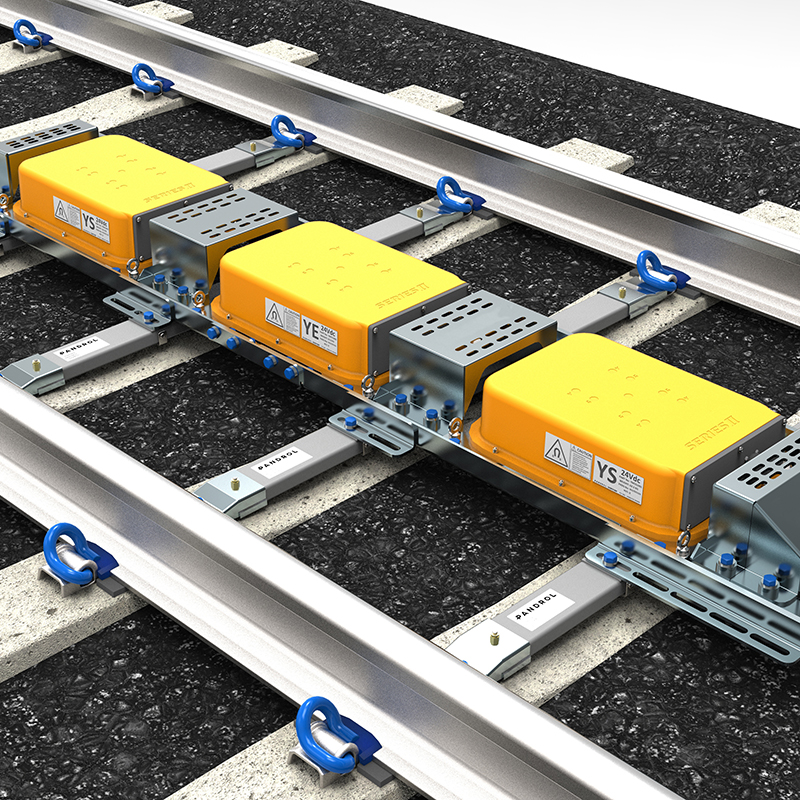

Vortok On-Tie Beam

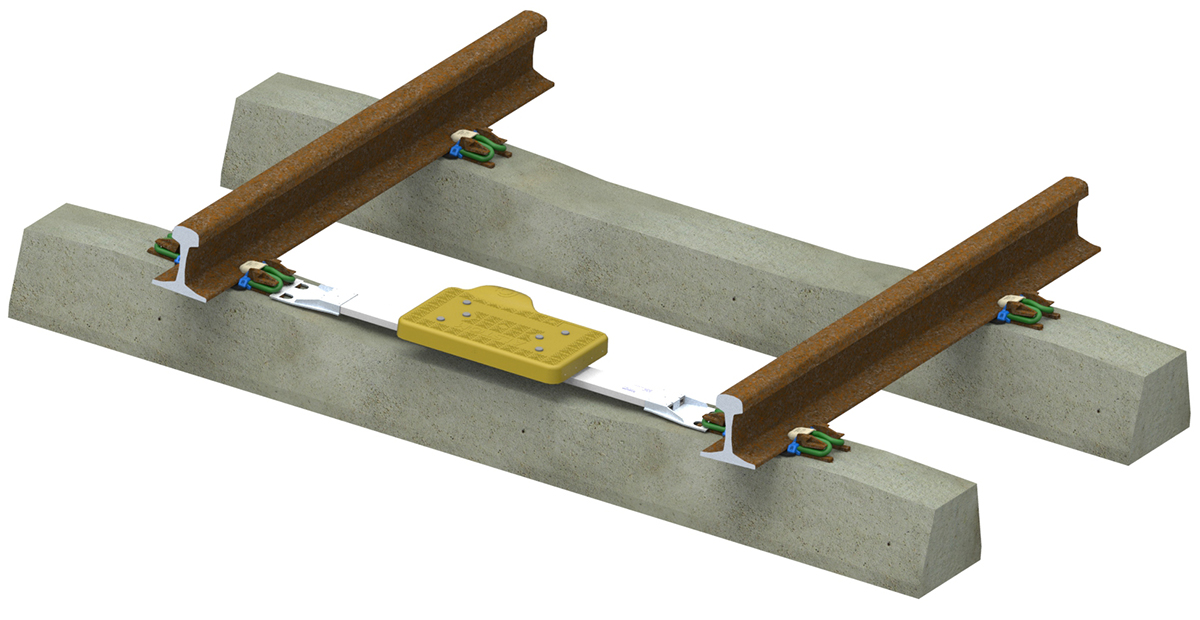

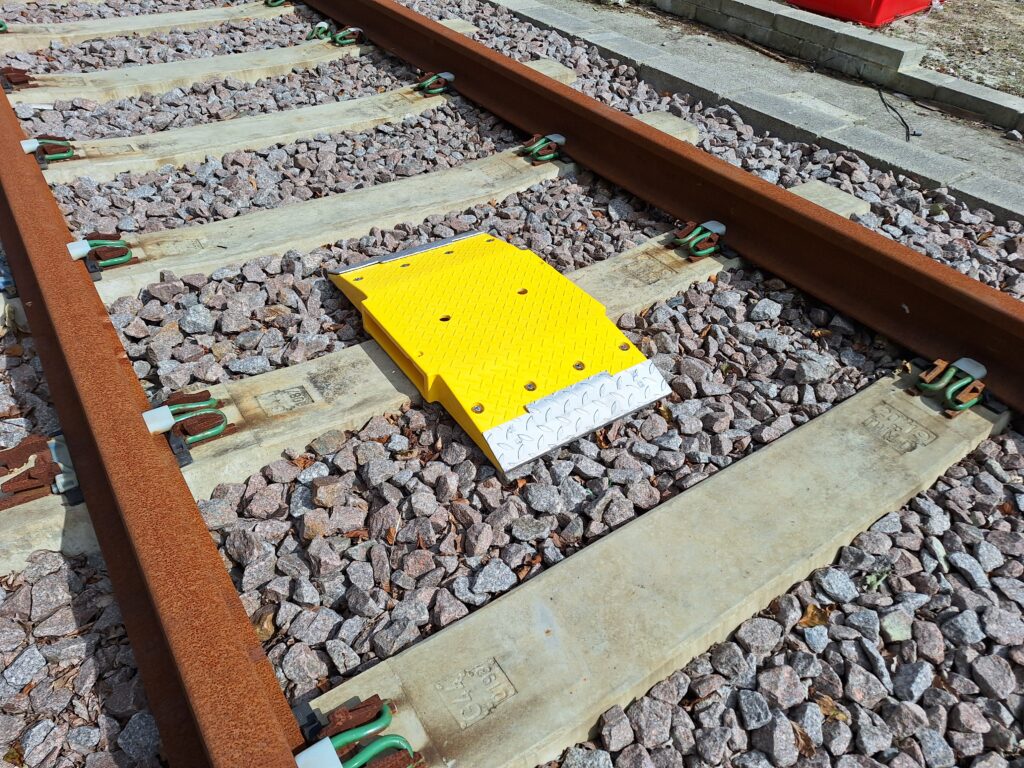

The On-Tie Beam is mounted over the tie onto the existing rail fastening, eliminating the need to drill the tie.

- Balises are used as beacons on European Train Control Systems (ETCS) to provide data through communication with train borne receivers

- Their accurate positioning and secure fitting are vital to ensure the reliability of the safety critical data they transmit

- Its design ensures that balises are installed in a compliant position, significantly simplifying the installation process and saving time and money

- The On-Tie Beam has been developed to withstand the adverse track environment and has been subject to rigorous approval processes around the world

Downloads

Benefits of the On Tie Beam

Easy installation

The On-Tie Beam is simpler to install, reposition and remove than other products. Eliminating the need for drilling into concrete ties, digging ballast and tamping saves time and reduces labour costs.

Money saving

Additional money is saved because the need for track possession during installation is eliminated or reduced.

Low maintenance

When balises are installed using the On-Tie Beam, lifetime ownership costs incurred as a result of repositioning for verification trials and maintenance are significantly reduced.

Non-intrusive installation

The On-Tie Beam’s simple, non-intrusive installation can be done using commercially available hand tools.

Compatible

Positioning the balise over the tie means that the product is compatible with automatic track tamping machinery.

Enhanced safety

With installation typically taking less than two minutes per balise, the length of time that a track worker is in a position of danger is reduced.

Technical features of On-Tie Beam

Compatibility

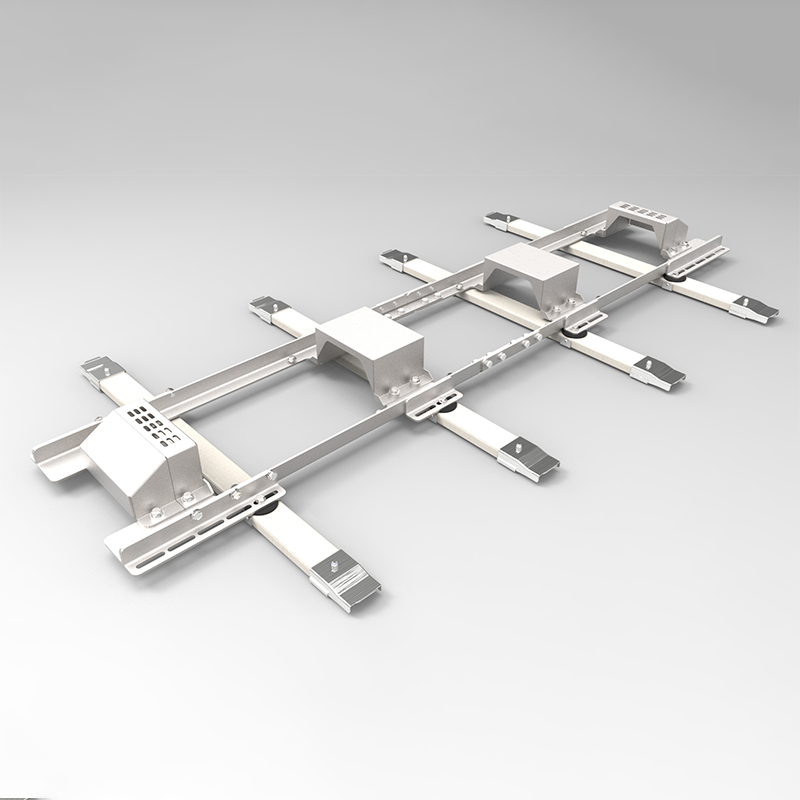

The On-Tie Beam is compatible with a range of track formations and with Siemens, Alstom, Bombardier and Hitachi balises. It can be installed on a wide range of tie types and is compatible with a range of track formations.

Resistance

It is vibration resistant to EN50125-3. It also has high resistance to chemical and climactic changes.

Non-conductivity

The On-Tie Beam’s non-conductive design ensures that it does not interfere with existing signalling systems.

Secure fastening method

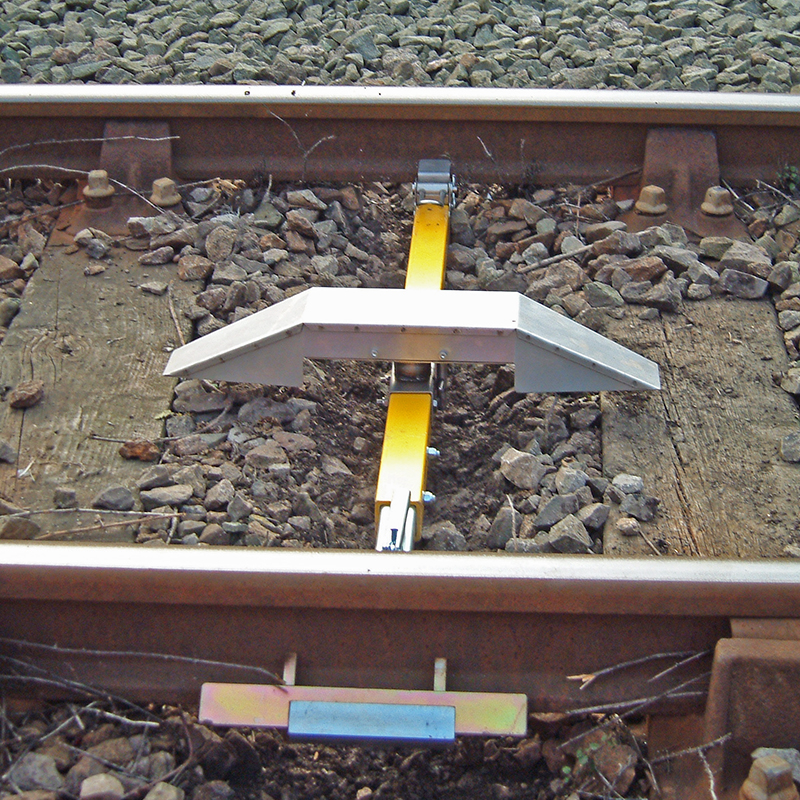

Its proven secure fastening method comprises a glass reinforced plastic (GRP) beam with stainless steel yokes that use the existing rail fastenings to hold the beam in track.

Designed for non-intrusive, rapid installation

When installing the On-Tie Beam, there is no need to modify the track or drill into concrete ties. Installation, repositioning or removal typically takes less than two minutes per balise and there is no wait for resins to cure.

Related products

The Balise Protection Device (BPD) is Pandrol’s latest addition to Pandrol’s signalling solutions.

Balise Protection Device (BPD)

Our robust and lightweight Signboard Supports can be quickly installed where there is a need to place signage for an emergency or temporary speed restriction.

Signboard Supports

Used in conjunction with our Signboard Supports, the Temporary AWS Magnets can be quickly and easily installed where there is a need to place an emergency or temporary speed restriction.

Temporary AWS Magnets

Automatic Power Control Magnets are used to instruct an electric locomotive to open the circuit breaker on its transformer, so it does not draw current as the pantograph traverses a neutral section, to eliminate arcing.

Automatic Power Control Magnet

Utilising our extensive experience with mounting beams, we have developed a range of rapid fit frames for use with our modular AWS magnets.

Rapid Fit Frames

All of the magnets can be fitted using the Pandrol Rapid Fit Frame System, with a typical installation time of 20 minutes for a double magnet assembly.

AWS Magnets Series 2

The Pandrol Clamp Beam Balise Mounting System is used to install balises (transponders) into track securely and efficiently.

Clamp Beam

The Adjustable CableGuard is a ‘fit and forget’ product that prevents track circuit failures by creating an insulating layer between the rail, sleeper and cable.