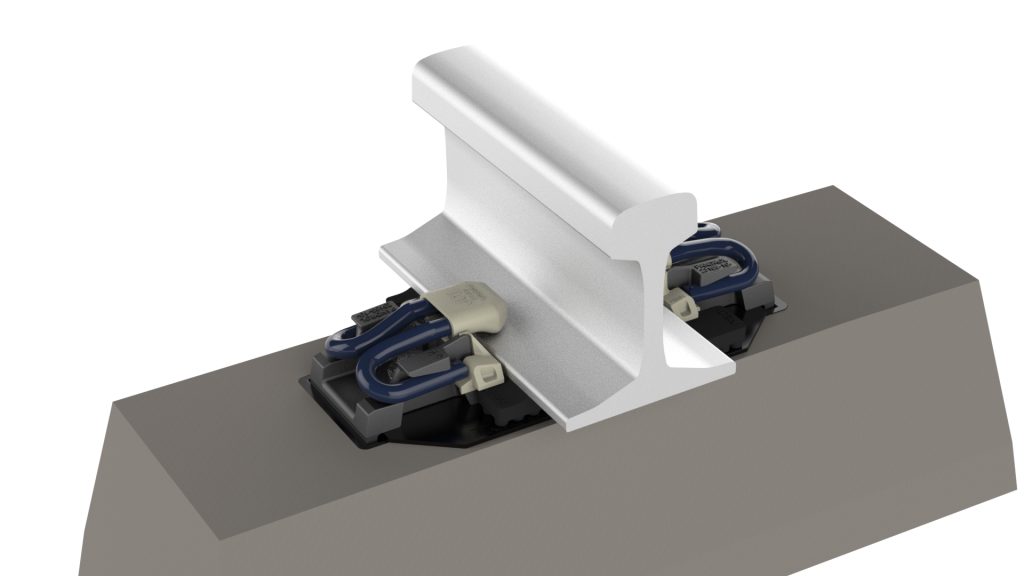

Fastclip FE RR

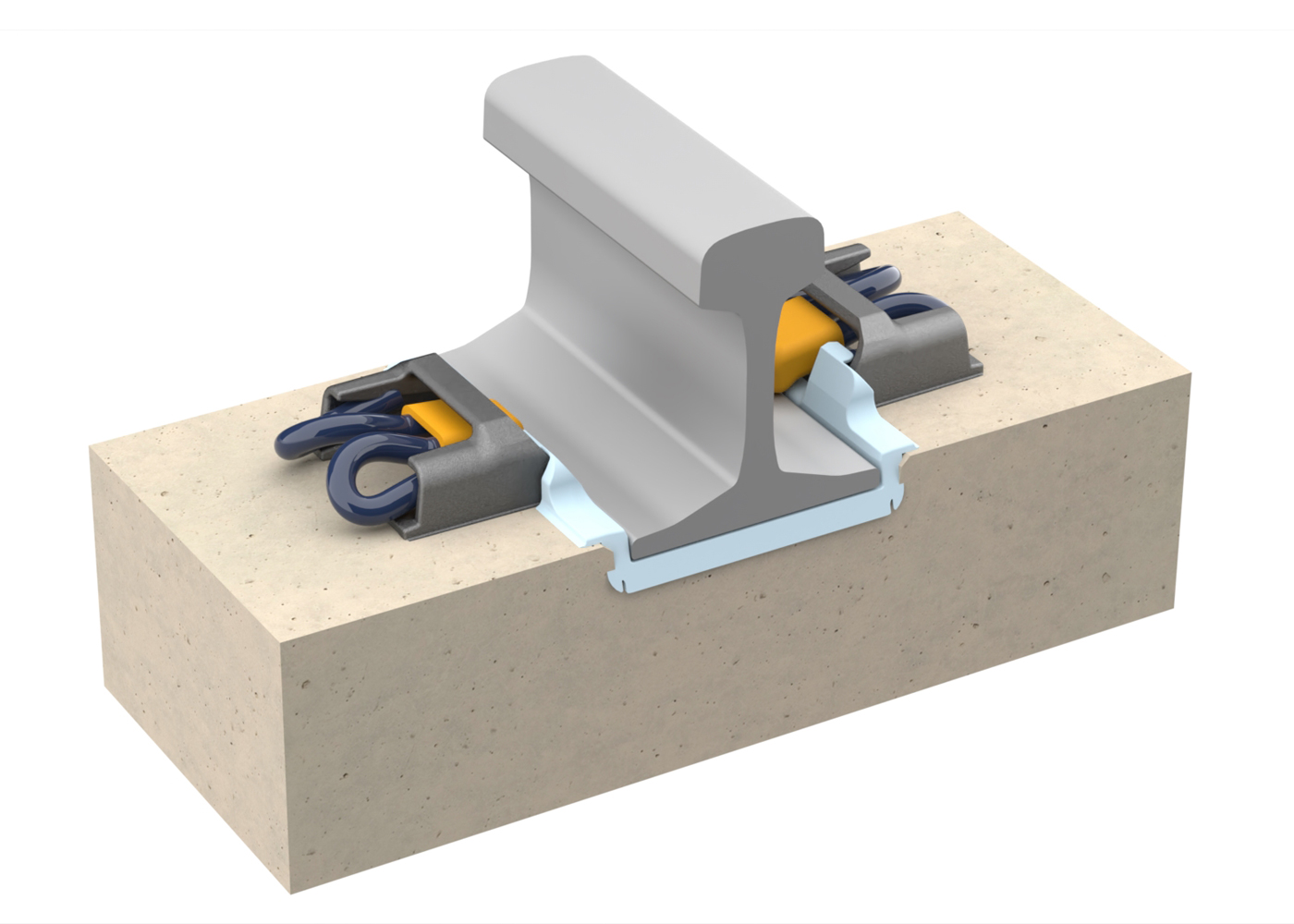

Fastclip FE RR sleepers are supplied to the track pre-assembled, with all components held captive and the clips set in parked position.

- Once the sleepers have been placed and the rail threaded, the clips are simply pushed into the installed position.

- A recessed rail seat and two-part combined rail pad and insulator help to ensure that the system provides long service life.

Downloads

Advantages of using Pandrol Fastclip FE RR

Heavy Haul performance

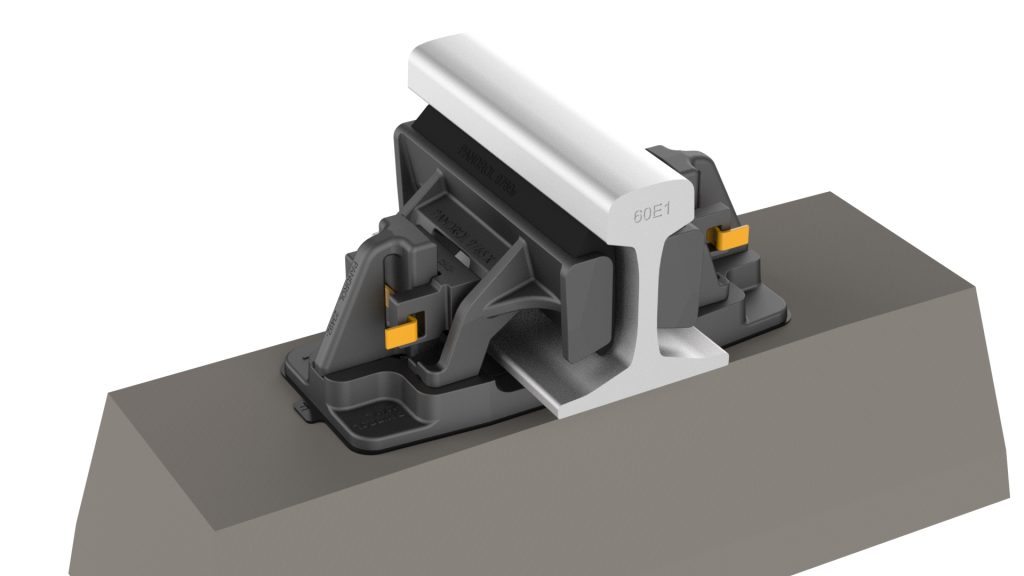

The Fastclip FE RR system has been specifically designed to provide exceptional performance in extreme heavy haul applications.

Efficient maintenance

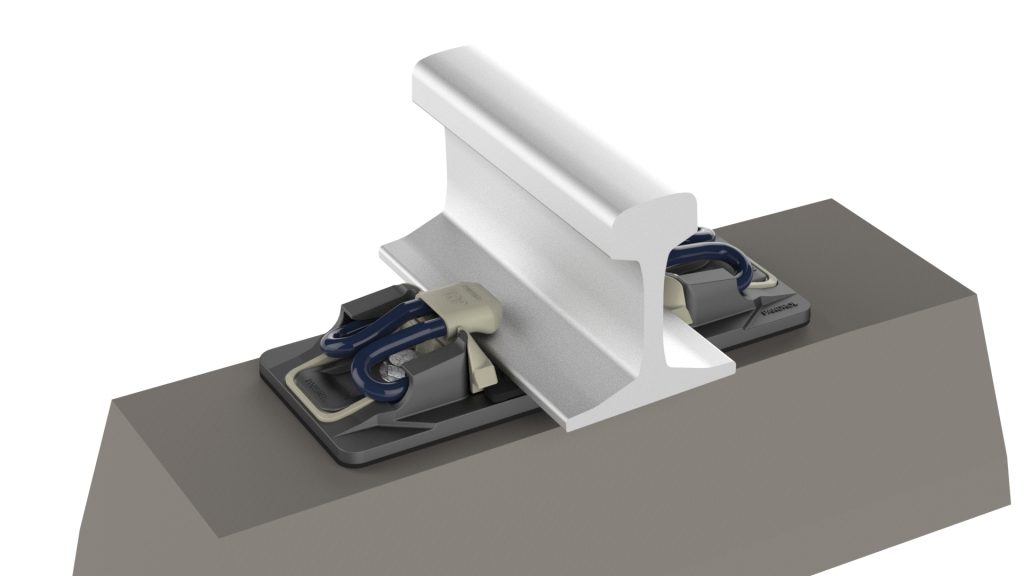

Delivered pre-assembled on the sleeper, the FE RR system’s captive fastenings and compatibility with mechanised equipment ensure efficient track construction and maintenance.

Switch-on Switch-off

The unique Pandrol ‘switch on-switch off’ function enables fast and efficient track installation and reduced maintenance costs.

Threadless technology

The threadless technology is ideally suited to extreme heavy haul operations, delivering high-quality track and low maintenance requirements.

Long Life

The system’s recessed rail seat and two-part combined rail pad and insulator ensure that components have a significantly longer life than other fastening systems.

Technical features of the Pandrol Fastclip

Clip type

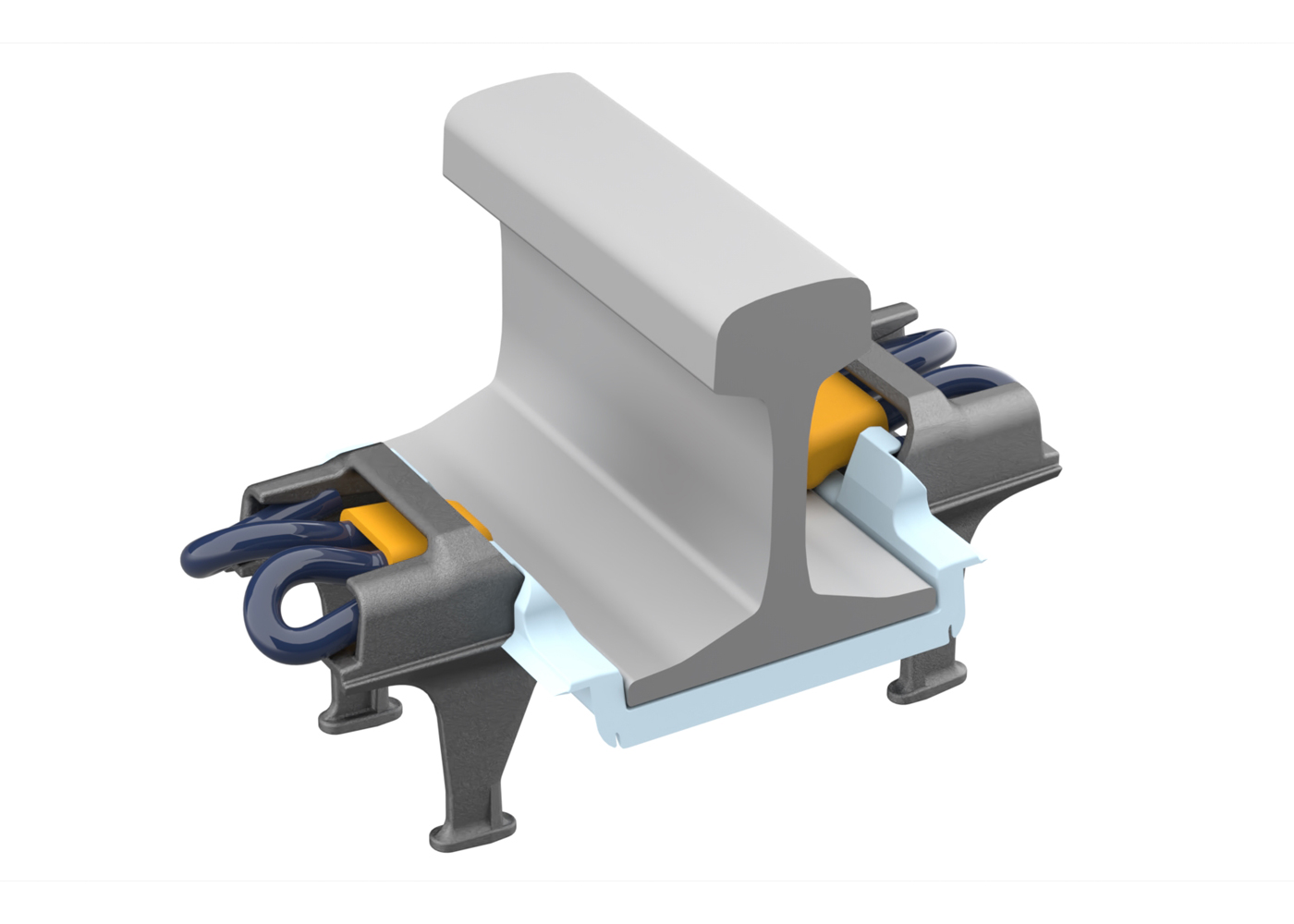

The FE RR system uses Pandrol Fastclip FE1505 clips for threadless, self-tensioned fastening.

Switch on-switch off function

The clips are supplied in the parked position, held securely but not intruding into the rail seat. They can then be switched quickly and easily into the installed position.

Captive fastenings

Sleepers are supplied to the track construction site as pre-assembled units, with captive fastenings and no loose components.

Mechanisation

Predominantly designed for mechanised track operation, Fastclip FE RR is compatible with a wide range of equipment. However, it is also suitable for manual installation where required.

Performance

The standard maximum axle load for the FE RR system is 40 tonnes. The minimum curve radius is 150m.

Related products

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

SICUT composite ties and bearers deliver superior performance, enhanced value, and significant environmental benefits compared to wood, concrete, and steel alternatives.

SICUT Composite Ties

Fastclip

SKL

This non-bonded, low-profile system is fully insulated and provides excellent stray current protection.

e-Clip SRS

NABLA Evolution is a direct rail fastening system that offers enhanced performance for tracks with tight radius curves. It has been proven in installations for several decades and is recognised for its simple installation and maintenance. By maintaining the track gauge, it significantly increases the life expectancy of assembly components.

NABLA Evolution

PR Clip

The system is optimised for slab track and is suitable for tramway and metro applications.