Victor Baseplate product overview

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

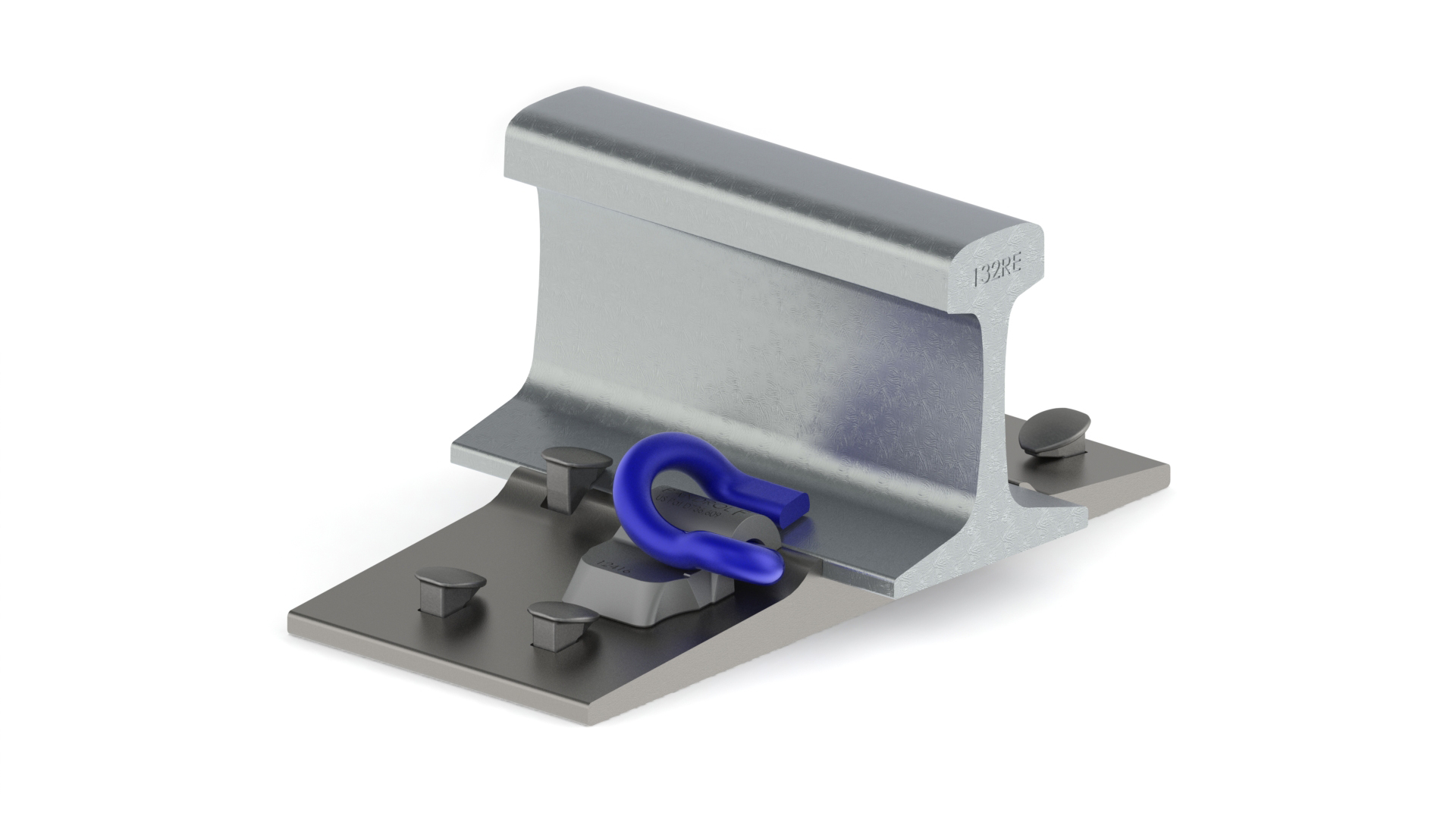

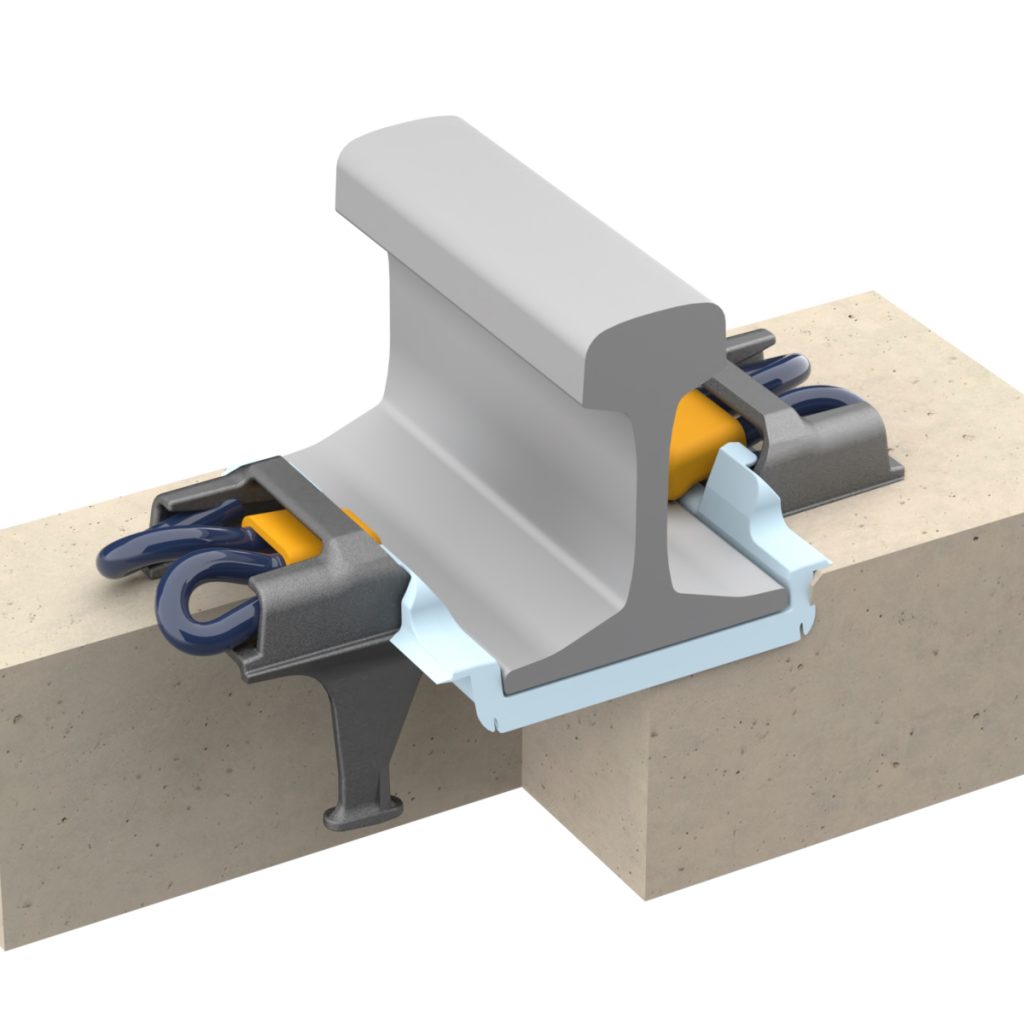

- The outcome is a rolled steel baseplate that provides maximum load bearing area, holding power and prevention of rail rollover

- Pandrol’s Victor baseplate system reduces maintenance

Downloads

Benefits of the Victor Baseplate

Increases track longevity

Compared to cast baseplates, the rolled steel Victor system is economical, strong and durable.

Money saving

The baseplates’ increased load bearing area results in a significant reduction in plate cutting, saving time and money.

Increased safety

The large bearing area also reduces gauge widening under load, preventing rail spreading and increasing railway safety.

Versatile

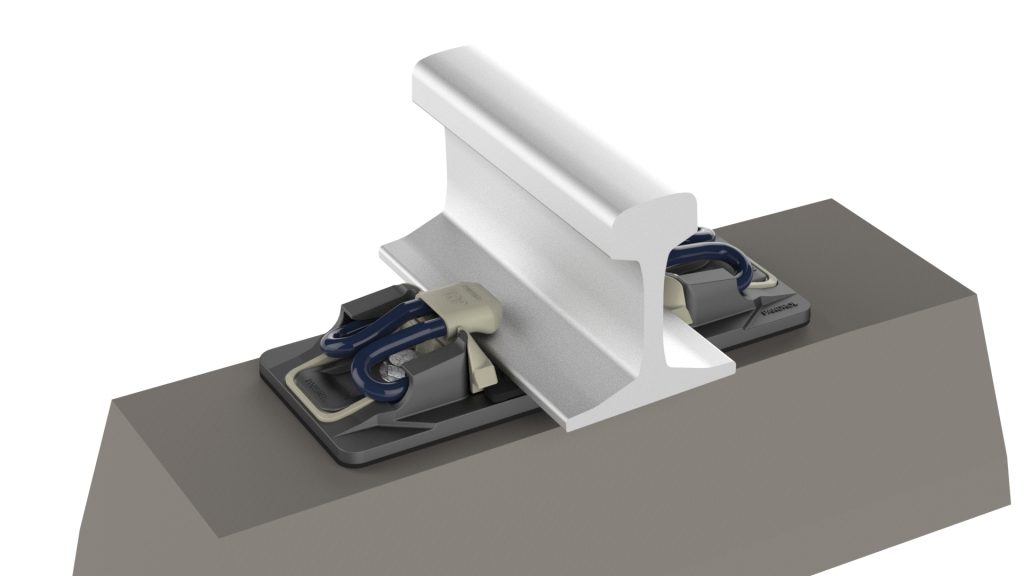

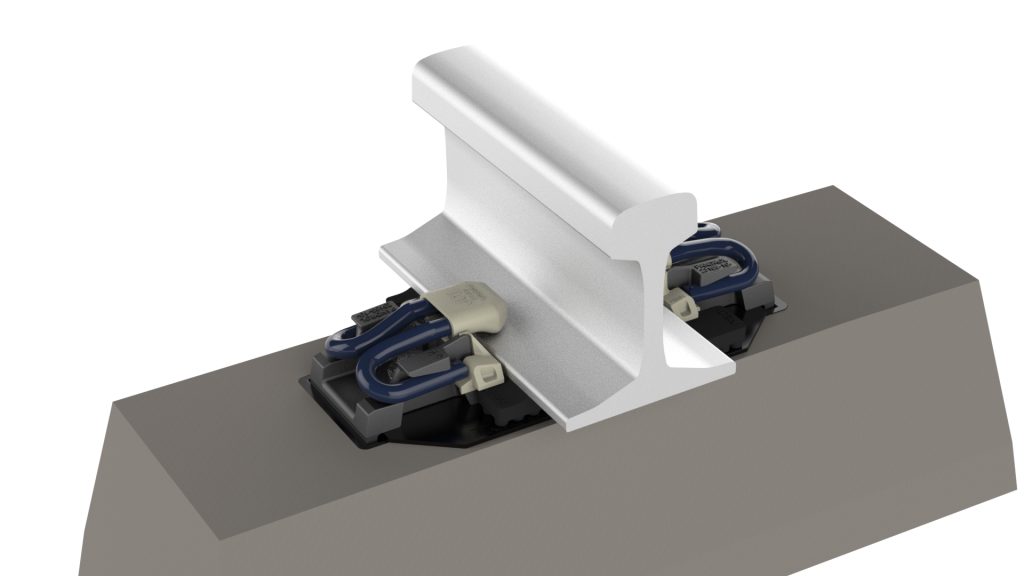

The Victor system is flexible and can be configured to different baseplate profiles and clip styles.

Compatible

Compatibility with resilient fastenings brings the accompanying advantages of holding power, prevention of rail rollover and reduced maintenance.

Low maintenance

Using the SWAGE method to attach the cast shoulders to the baseplates means no extra components, such as bolts, rivets or weld filler, are required.

Technical features of Victor Baseplate

Rolled steel construction

Victor baseplates are made from strong, durable rolled steel.

Increased load bearing area

The Victor baseplate has a 37% greater load bearing area compared to similar baseplates for resilient fastenings.

Cast iron shoulders

Lightweight, cast ductile iron shoulders provide the geometry needed to attach resilient rail fasteners. A cold forging method called SWAGE is used to attach the cast shoulders to the rolled steel baseplates.

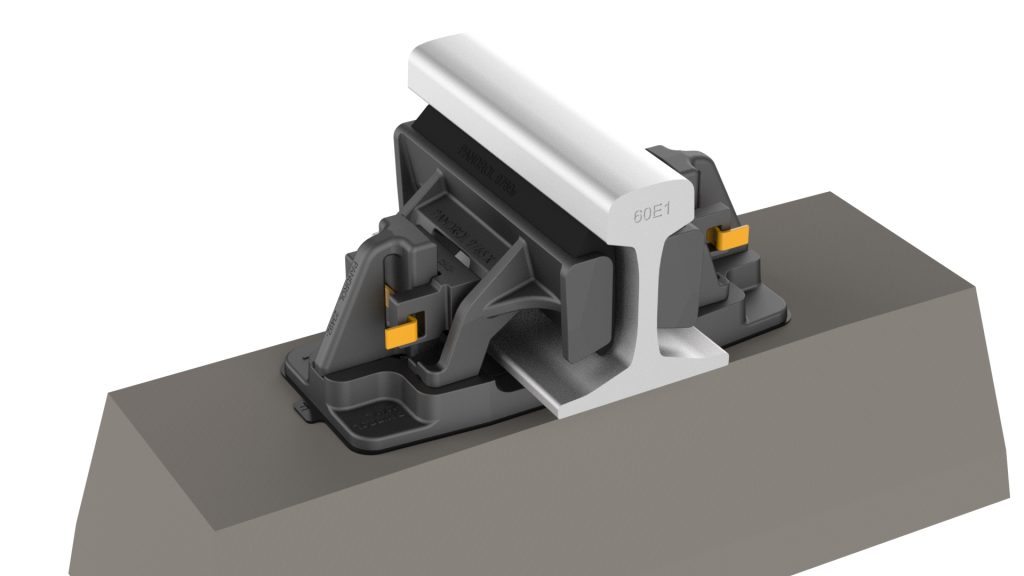

Resilient fasteners

The Victor system is compatible with Pandrol’s resilient fasteners, including the e-Clip and Fastclip.

Versatility

The baseplate comes in 16” and 18” lengths and is available for both screw and cut spikes.

AREMA compliance

The Victor baseplate is tested and compliant with resilient fasteners, as recommended by AREMA 30.

Related products

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

SICUT composite ties and bearers deliver superior performance, enhanced value, and significant environmental benefits compared to wood, concrete, and steel alternatives.

SICUT Composite Ties

Fastclip

SKL

This non-bonded, low-profile system is fully insulated and provides excellent stray current protection.

e-Clip SRS

NABLA Evolution is a direct rail fastening system that offers enhanced performance for tracks with tight radius curves. It has been proven in installations for several decades and is recognised for its simple installation and maintenance. By maintaining the track gauge, it significantly increases the life expectancy of assembly components.

NABLA Evolution

PR Clip

The system is optimised for slab track and is suitable for tramway and metro applications.