WEL-D’STRESS® Hammer

The WEL-D’STRESS® hammer has been developed by Pandrol to improve the fatigue resistance of aluminothermic welds.

The WEL-D’STRESS® hammer introduces residual stresses of compression and prevents the appearance of fatigue stains when traffic is intense. The hammering procedure involves using the hammer for one minute from the web/head connection to the tip of the foot on either side of the collar (i.e. a minimum of four minutes for one weld).

When traffic is heavy, fractures can occur in welds in sensitive areas within six months of welding. Use of the WEL-D’STRESS® hammer completely removes this risk. Customers using the equipment since 2007 have found that the life expectancy of welds in high-traffic areas is identical to that of the rail.

WEL-D’STRESS® Hammer product overview

The WEL-D’STRESS® system introduces residual stresses of compression and prevents the appearance of fatigue stains when traffic is intense.

- The hammering procedure involves using the hammer for one minute from the web/head connection to the tip of the foot on either side of the collar

- When traffic is heavy, fractures can occur in welds in sensitive areas within six months of welding

- The life expectancy of welds in high-traffic areas is identical to that of the rail.

Downloads

Benefits of the WEL-D’STRESS® Hammer

Increases track longevity

Using the WEL-D’STRESS® hammer results in a very significant increase in the length of time before an aluminothermic weld shows signs of fatigue.

Low maintenance

Less maintenance is needed – the life expectancy of welds in high traffic areas is identical to that of the rail.

Value for money

As a result, maintenance costs are reduced and the system offers optimised life cycle cost (LCC).

Increased availability

There is increased availability of the infrastructure.

Easy installation

The WEL-D’STRESS® hammer is easy to transport and use.

Versatile

The equipment is efficient and effective for welding on all types of rail and very high traffic networks.

Technical features

Pneumatic system

The WEL-D’STRESS® hammer is a pneumatic system.

Usable with cold and hot welding

WEL-D’STRESS® can be used with aluminothermic welds from ambient temperature up to 300°C maximum.

Designed for ease of use

The equipment has been designed to be extremely easy and intuitive to use.

Compact size

The kit is compact and easy to carry. It comes in a strong case, certified IP67.

Versatility

The WEL-D’STRESS® hammer can be used on all types of rail and very high traffic networks. This includes heavy haul lines and intense urban traffic networks, such as RER and Metro.

Related products

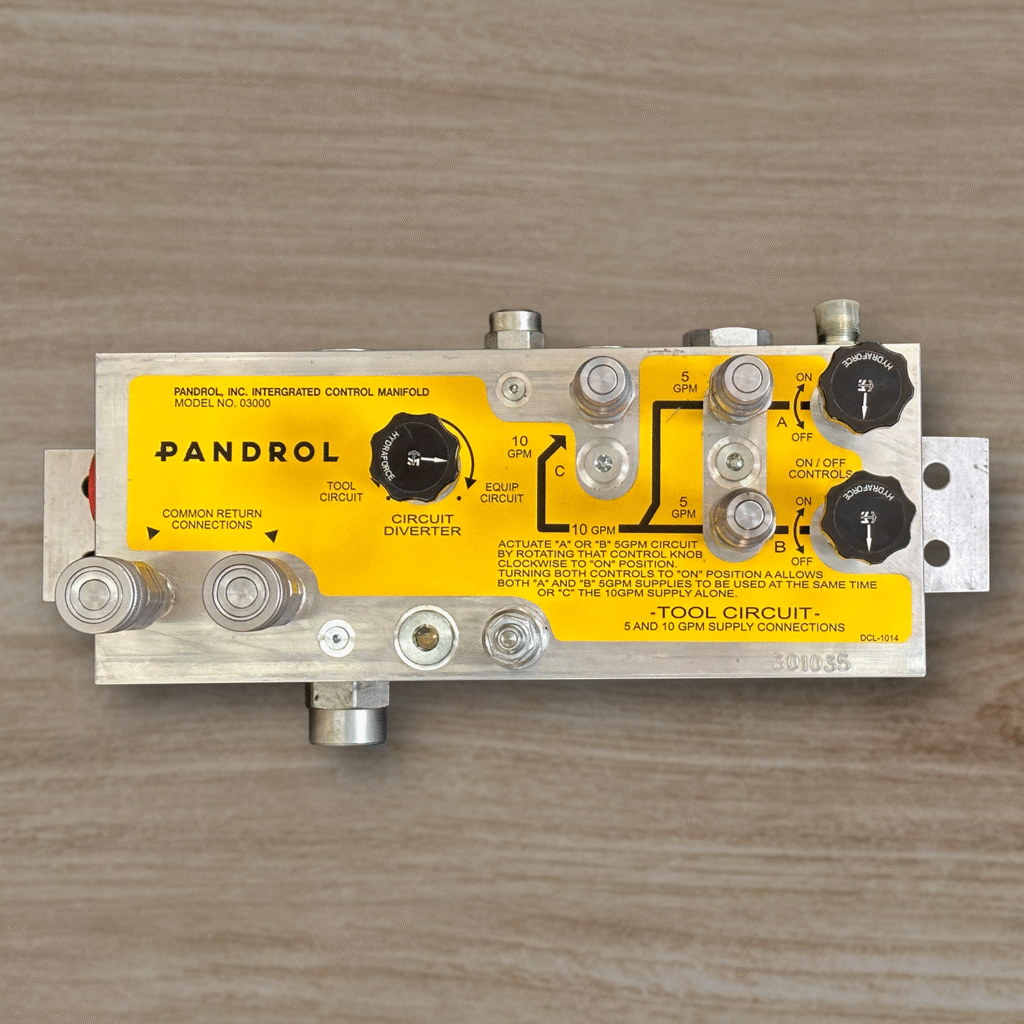

The Hydraulic Manifold Circuit is a self-contained flow and directional control assembly. Compact and easy to install, this manifold provides a safe and cost-effective way of adding hydraulic tool capabilities to your existing range of equipment.

Hydraulic Manifold Circuit (03000)

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The Pandrol Weld Shear is designed to make it easier and more efficient to remove excess weld metal.

Weld Shear (05100A)

A powerful spike puller for rail maintenance.

Light-weight Two Stage Spike Puller (01100RM)

The Pandrol 6″ Cup Stone Grinder is a versatile tool designed for grinding the tops of frogs and the rail.

6 inch Cup Stone Grinder (04800-04850)

The Pandrol Surfacing Guide is a rugged but lightweight grinding attachment designed specifically for grinding the top of the rail.

Surfacing Guide Grinder (00700-00700C)

Pandrol’s Profile Grinder (06000B) is a lightweight, precision grinding machine designed specifically for the finish grinding of field welds.

Profile Grinder (06000B)

Pandrol’s Dual Circuit Power Unit (00100K) is a freestanding, easy-to-transport hydraulic power unit.

Dual Circuit Power Unit (00100K)

The equipment can be used for normal gap, wide gap and head wash repair (HWR) welding.

i+cool

The 1” wrench is safe and efficient to use, with an anti-vibration design and an optional handle to provide the optimum work position for the task at hand.

Impact Wrench (02500)

With four-axis precision and the ability to use both straight and cup stones, this tool ensures quality grinding in the field.

Precision Frog Grinder (09200A)

Pandrol Straight Stone Grinders are powerful, safe tools designed for a wide range of rail grinding applications, including field welds, frogs, and switch points. Available in four models – clockwise rotation (04600), clockwise rotation with trigger (04650), counterclockwise rotation (04700), and counterclockwise rotation with trigger (04750) – these grinders cater to various operational needs. The models without a trigger feature an on-off valve for control. All models are housed in high-strength aluminum with rigid handles, enhancing both durability and operator safety.