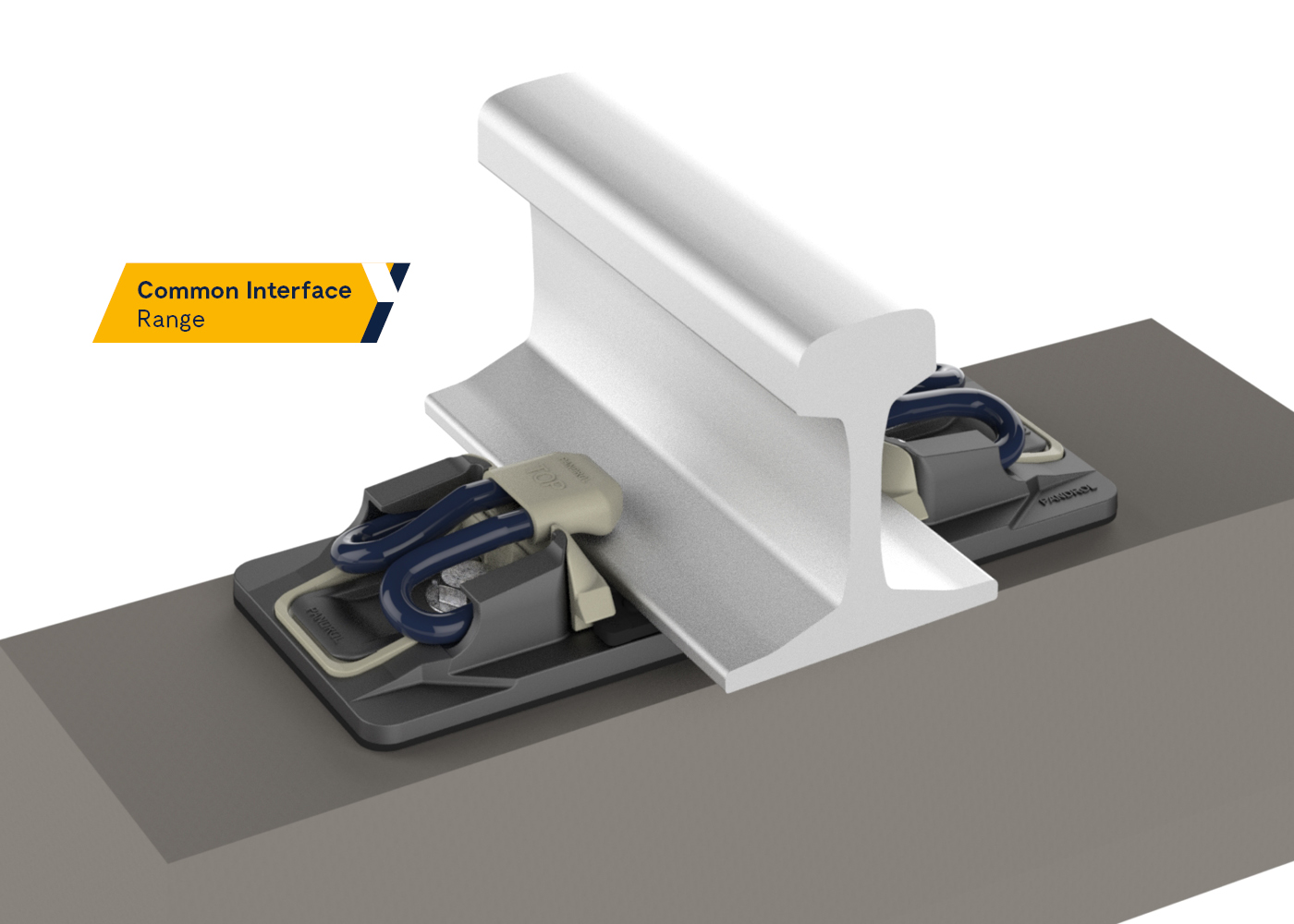

DFC Common Interface

Pandrol’s DFC Common Interface (CI) has been designed to futureproof non-ballasted track. DFC CI is part of our Common Interface range.

Pandrol’s Common Interface System provides a common connection point for a range of different direct and indirect fastening assemblies. A common base accommodates three different fastenings: FCA, DFC and Vanguard. As a result, when noise and vibration mitigation requirements change, rather than having to modify or replace the whole track, the fastening system can simply be swapped out.

DFC Common Interface product overview

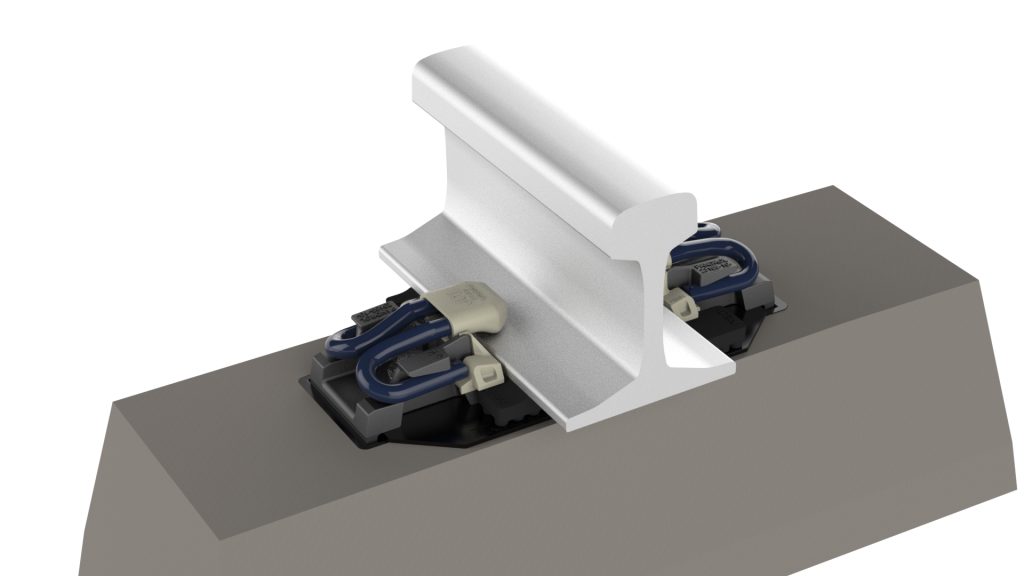

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

- When noise and vibration mitigation requirements change, rather than having to modify or replace the whole track, the fastening system can simply be swapped

- The DFC offers all the advantages of a double resilience Fastclip baseplate system in terms of safety, reliability and durability

- A wide range of vertical and lateral adjustments can be achieved with minimal tools and components, allowing for efficient heave and gauge adjustment and correction for track settlement

Downloads

Benefits of the DFC Common Interface

Increased flexibility

The high degree of flexibility offered by being able to change the fastenings on the common interface allows for greater futureproofing of non-ballasted track than in the past. Where noise and vibration concerns demand changes to stiffness, instead of having to modify or rebuild the whole track, the fastening system alone can be changed. This saves time, results in minimal disruption to track access, and saves a huge amount of money.

Easy installation

The DFC has been designed for ease of installation and maintenance with minimal tools, cutting maintenance inventory and time.

Low ground-borne vibration

The DFC can be fitted with a low stiffness assembly (16–25 kN/mm), resulting in exceptionally low ground-borne vibration.

Electrical insulation and corrosion protection

The system provides full electrical insulation and corrosion protection.

Versatile

Available in low toe load and zero longitudinal restraint (ZLR) configurations, the DFC is suitable for bridge and viaduct applications. It can be used for stiffness transitions using variable stiffness rail and baseplate pads.

Low maintenance

The commonality of the DFC simplifies tooling, inventory and training for concrete plants.

Technical features of the DFC Common Interface

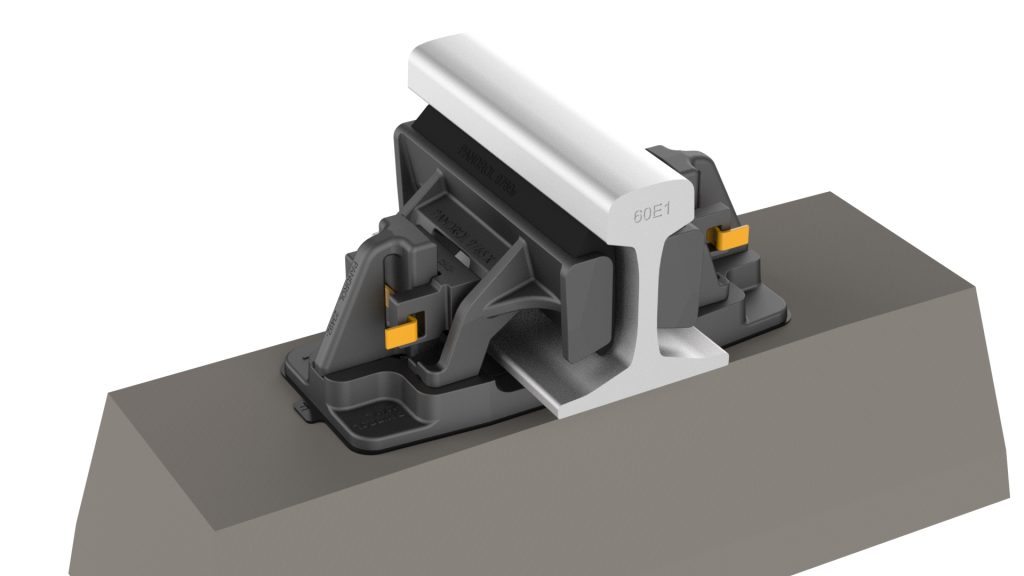

Common interface

The DFC shares a common interface can accommodate FCA, DFC and Vanguard fastening systems, allowing for different levels of stiffness (resilience) without changing the substrate.

Vertical and lateral adjustment

With the addition of a raiser, corrections of up to 60mm can be made to the rail head height. If ground heave is a possibility, raisers can be incorporated into the DFC for ease. Total track gauge adjustment of 20mm (10,, per rail seat) can be made adjusting the gauge of interchangeable side post insulators to move the rail within the baseplate (the baseplate remains fixed).

Indirect rail holding

DFC is an adjustable indirect rail holding mechanism that, being separate from the substrate and with two pads (rail and baseplate), provides a high level of sound, vibration and electrical insulation.

Fastclip compatibility

The DFC is fully compatible with Fastclip rail fastenings, with a clip ‘park position’ included on its shoulders. Fastclip’s compatibility with automated clipping machines allows for rapid clipping and unclipping.

Easy maintenance

The system has been designed to ‘fit and forget’, with minimal maintenance. Its shoulders include features to allow Pandrol de-stressing rollers to be fitted, increasing maintenance efficiency.

Recyclability

The DFC is composed of recyclable materials.

Related products

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.