Heavy Haul

Keeping freight moving

Pandrol has over 40 years experience in Heavy Haul rail and has a full range of products for axle loads up to 40 Tonnes. Our products and technical expertise have shaped all of the major heavy haul railways in the world with a track record covering more than 4 decades and extending across all continents.

As we have developed our product range and introduced new technologies we have applied those technologies to the requirements of heavy haul. Today we have a full range of products for axle loads up to, and above, 40 Tonnes for operating railways.

Our products and equipment have been developed to withstand a huge variety in environmental and climatic conditions. Our customers, the main Heavy Haul operators in Africa, Australia, Brasil, Canada and the USA all have different operating environments, climates and local conditions which gives us a unique understanding of the Heavy Haul needs across different territories.

Our products

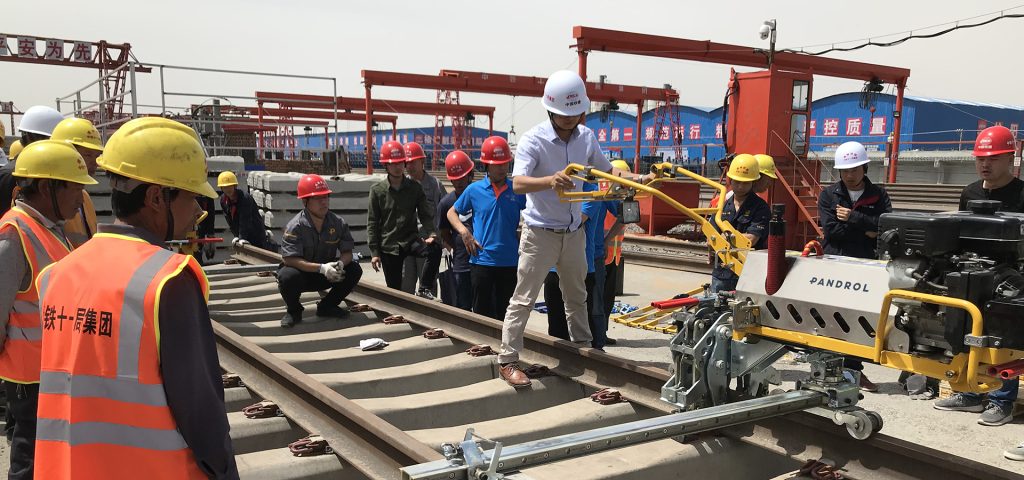

This robust and reliable self-propelled machine now has an EU Stage 5 diesel engine from Hatz and a new intelligent control system. The machine installs 4 clips simultaneously across two rails and has a sleeper lift function for new construction projects.

Clip Driver CD400SP IQ

Pandrol’s original design e-Clip systems are manufactured to one global standard and are produced worldwide at Pandrol’s various manufacturing facilities.

e-Clip

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip

Manufactured specifically for excavators weighing 10 to 16 tonnes, the Hy-Rail attachment offers stability and flexibility when working on track. All movement is controlled from the driver’s cabin, and the hydraulics work without the need for additional swivel implements

Hy-Rail 10-16T

Pandrol Under Sleeper Pad (USP) solutions reduce maintenance requirements, increase track quality and provide vibration attenuation to Ballasted Track.

Under-Sleeper Pads

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

Download our heavy haul magazine

We have shaped major heavy haul railways in every continent, ensuring rail infrastructure availability across the globe.