e-Clip

The Pandrol e-Clip rail clip fastening is the preferred fastening system of rail operators across the globe thanks to its versatility and track record for high performance. The ballasted, non-threaded, self-tensioning railway e-Clip system has been installed in over 50 countries across hundreds of applications – covering virtually every possible known rail section.

e-Clip explained

The popularity of our original e-Clip rail fastening means it has attracted many imitators over the decades, but none with Pandrol’s track record for success. Known previously as simply the Pandrol clip, this mature fastening system is favoured for its versatility and is widely used across global rail projects that face a range of parameters and challenges.

e-Clips are manufactured worldwide to the very highest quality at our very own manufacturing facilities. Their spring steel construction is optimised for strength and durability, and suitable for installation on wood and concrete sleepers.

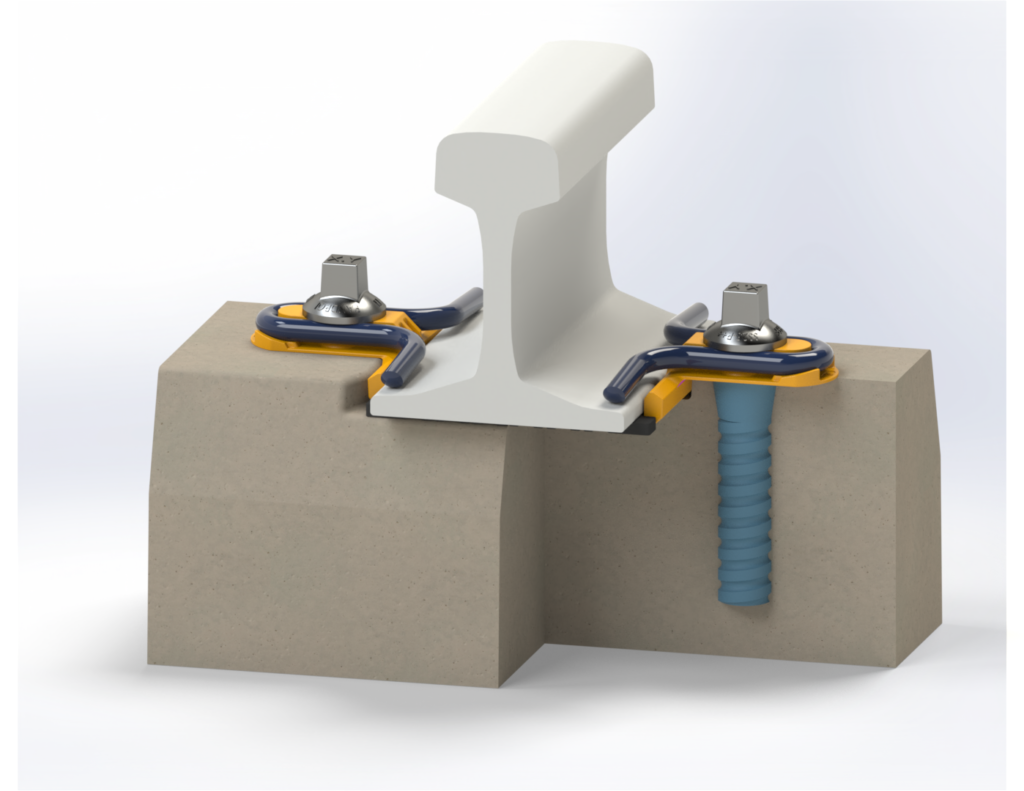

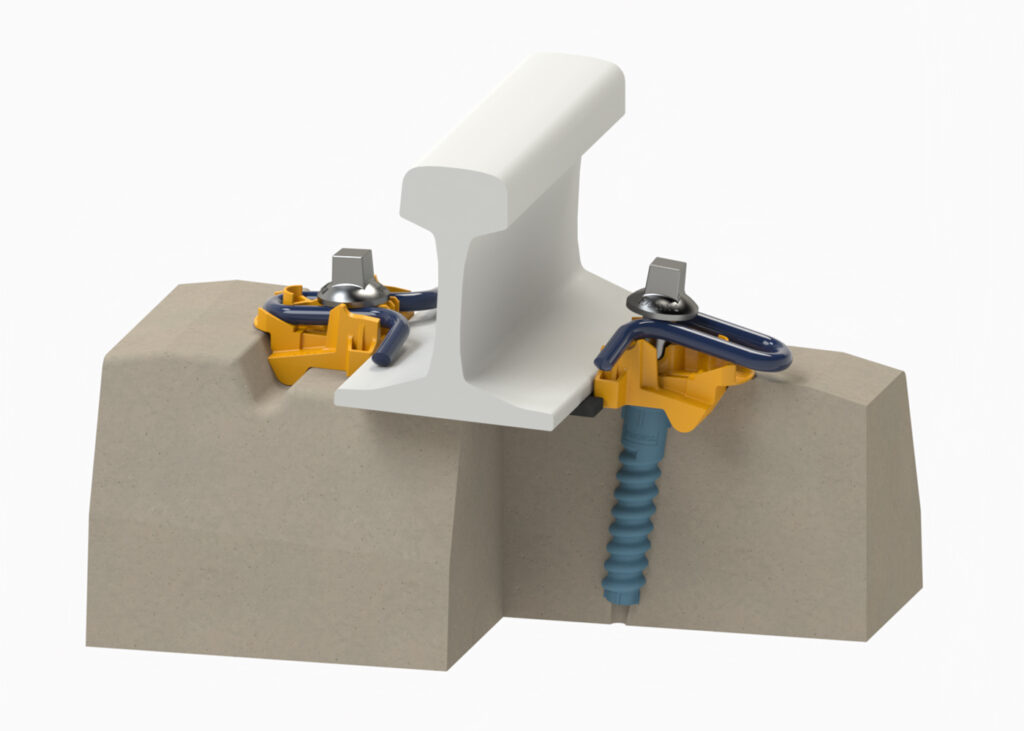

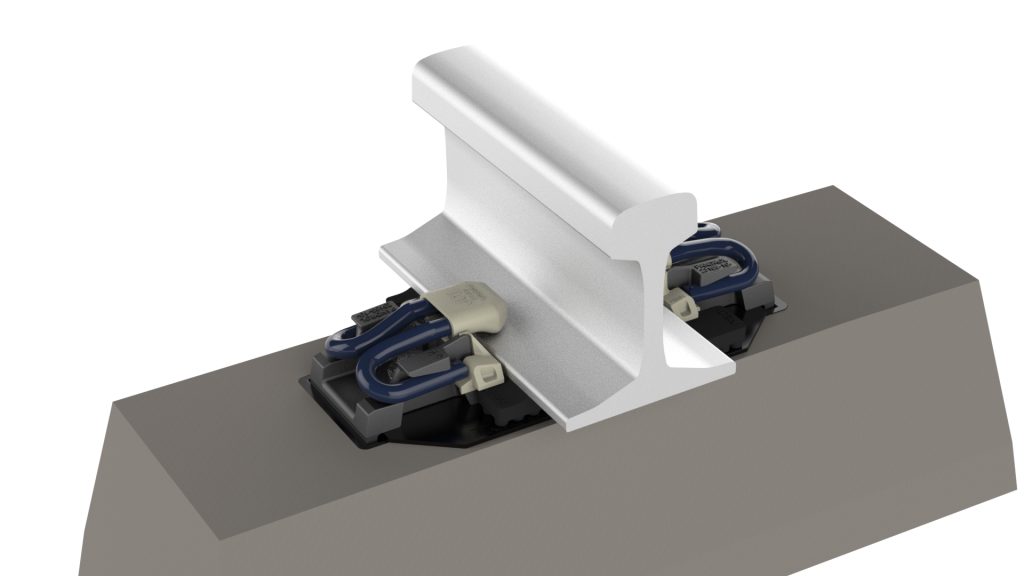

The Pandrol railway e-Clip consists of two elastic rail clips, two rail shoulders, one rail pad and two rail insulators, and is manufactured to one global standard for consistency. This spring-type clip ensures permanent elastic clamping complete with creep resistance and twisting resistance, making the fastening ideal for continuously welded tracks. Tension is achieved through insertion into a lug positioned parallel to the rail foot.

- A safe, reliable Pandrol clip, originally designed by our experts

- Meets the requirements of every rail application and environment

- Suitable for all market segments

Downloads

Advantages of the Pandrol e-Clip

Safe and reliable

Despite continuous innovation across the industry, rail systems around the world still request the e-Clip fastening for their projects thanks to its ongoing reputation for safety and reliability. Since the original e-Clip design, we have maintained its iconic shape and function, with updates for the modern rail system that mean Pandrol’s original rail clip is as sought-after as ever.

Self-tensioning

Fit and forget about this high-performing rail clip. The e-Clip is designed to be self-tensioning, meaning you can rely on optimised results without the need for regular manual checks and adjustments of the torque. This unlocks more efficient rail system operations by reducing the need for maintenance checks.

Versatile

Since its creation in the 1950s, the original e-Clip design has been adapted and added to, offering rail operators a choice of Pandrol clips to suit every application, environment and market segment. From the DRS system to the e-Clip SRS, Pandrol e-Clip can be combined with several baseplates and other elements to suit the parameters of every project.

Technical features of the e-Clip

The original patented design

e-Clip is the original Pandrol rail clip that stood the test of time. This iconic fastening system is recognised by rail operators across the globe and has an iconic reputation as durable, reliable, and easy to fit. Today’s e-Clip is an evolution of the original patented technology that first gained fame in the 1950s, and uses the signature ‘e’ shape which became the industry standard for rail clip fastenings.

Customisable elements

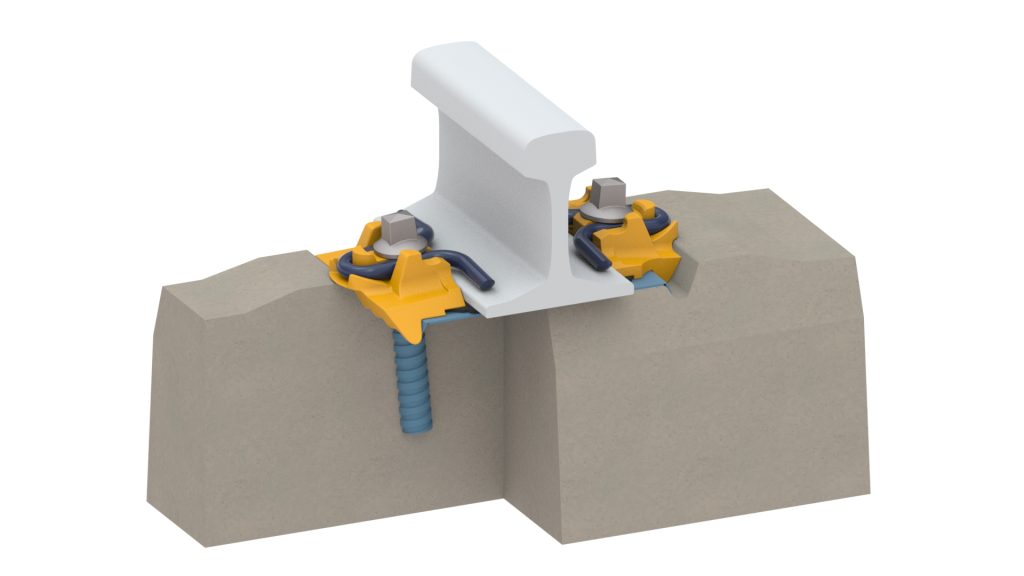

Tailor e-Clips to your specific rail system. Pandrol e-Clip is the chosen fastening for projects across the globe thanks to its versatility. Customers can choose the stiffness of the elastic rail pads, the type of baseplate fastening – including coach screws, angled guide plates and push-through bolts – and corrosion protection if required for the environmental conditions of their rail system.

Optimised for a long service life

Rely on the original Pandrol clip to deliver a long service life for your rail system, with minimal need for repairs or replacements. The threadless, self-tensioning system is low-maintenance and requires little to no manual intervention throughout its lifespan, leading to it being labelled a fit-and-forget solution. The strong creep and resistance and permanent elasticity make the e-Clip ideal for continuously welded tracks.

Related products

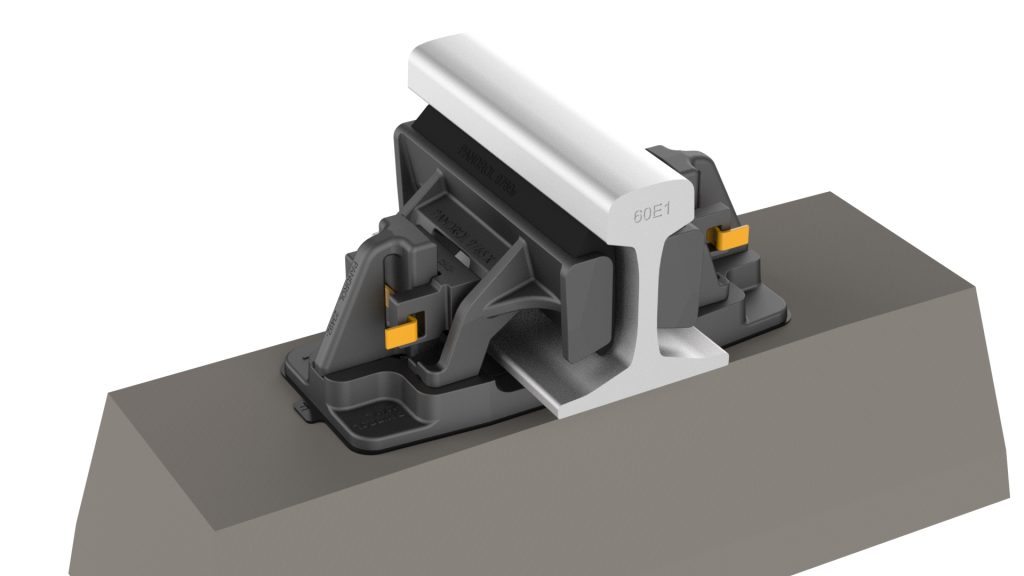

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

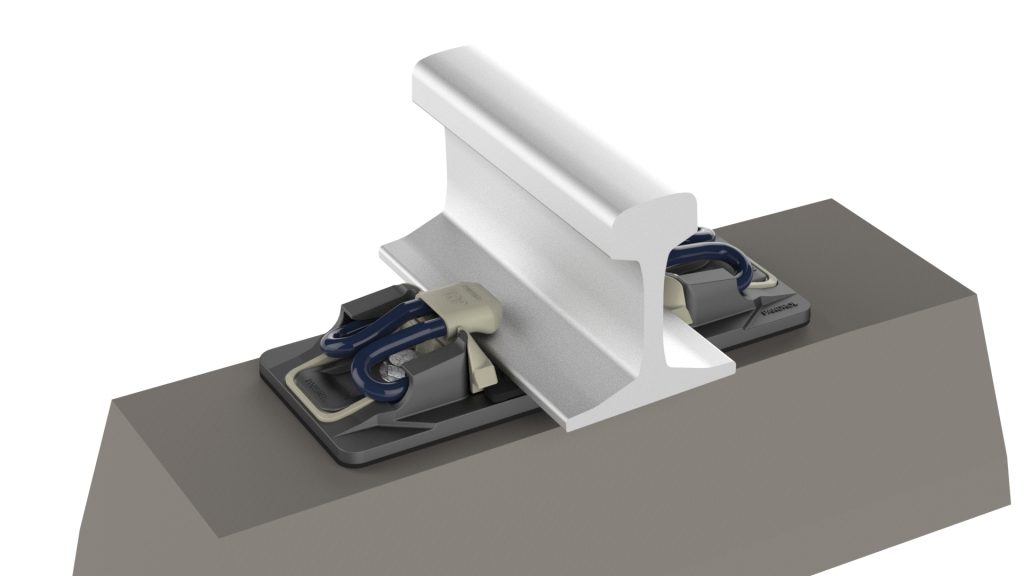

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

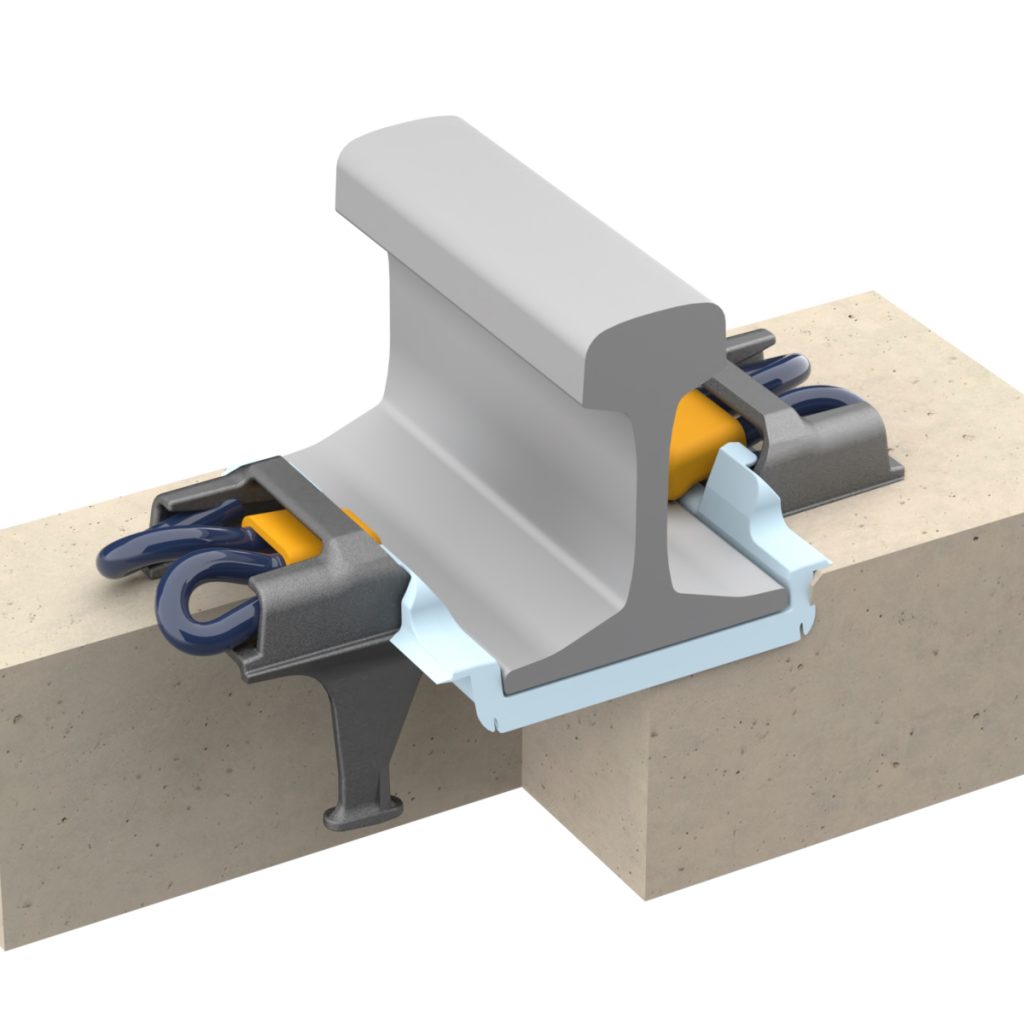

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip