SD-E product overview

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

- SD-E delivers higher rates of construction thanks to its efficient controlled clip guidance from parked to the in-service position.

- Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

Downloads

Benefits of the SD-E

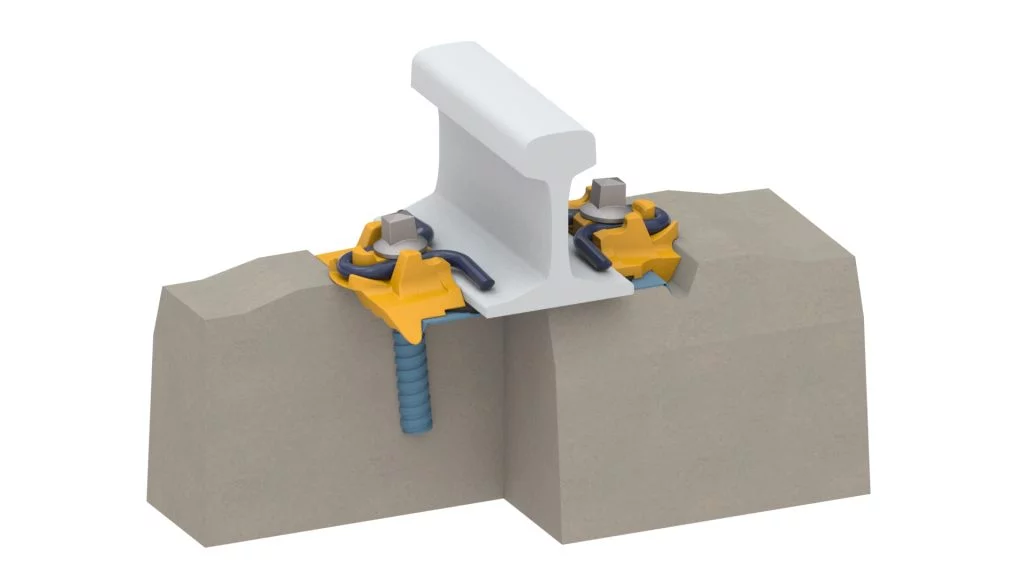

Pre-assembled

The SD-E system’s pre-assembled captive fastening units enable very high rates of track construction and maintenance. This efficiency translates into huge savings in labour, as well as reduced distribution and handling costs throughout the system’s life cycle.

Reduced carbon footprint

The SD-E is an extremely environmentally-friendly fastening solution. reducing the CO2 footprint, logistics costs and environmental impact.

Innovative design

The innovative geometry of the SD fastening improves track stability, prevents dust and impurities entering the dowel, and solves the problem of ballast entrapment.

Technical features of SD-RE

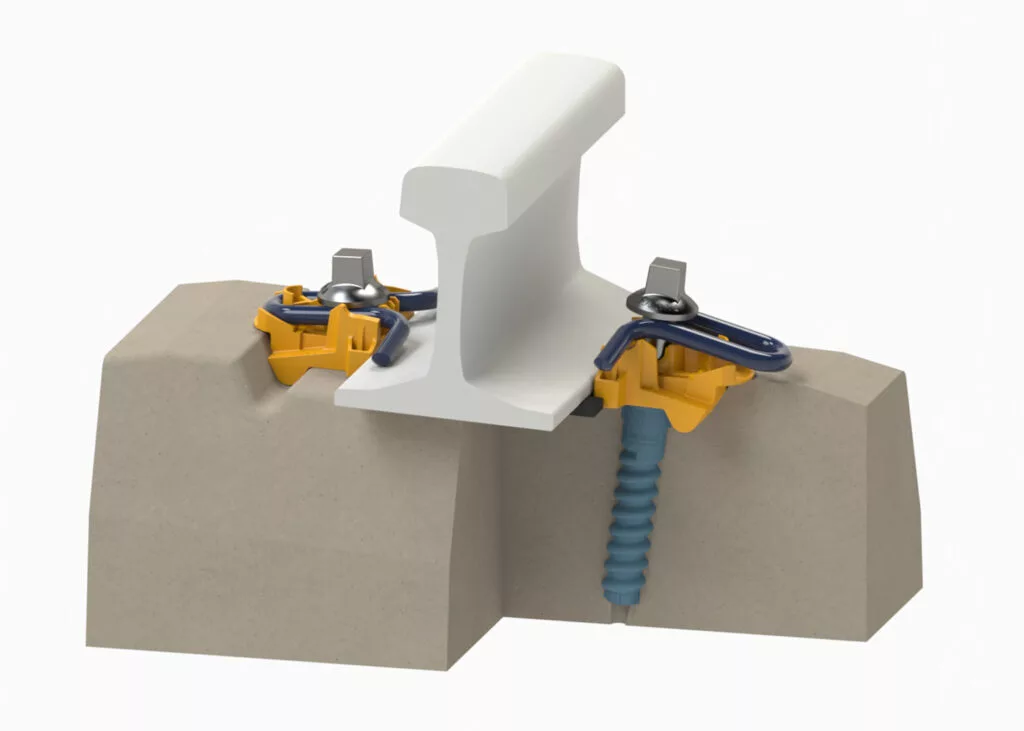

Captive fastening

SD-E sleepers can be supplied to sites fully pre-assembled, with all components remaining captive during construction and maintenance activities.

Eco-design

Compared to other screwed solutions, the clip is relatively low weight. This reduces its environmental impact and logistics cost without compromising on performance.

Increased robustness & Lifecycle

The clip has been modified to avoid frequencies where destructive amplitudes are generated, causing the clip to fail in fatigue. A significant increase in the natural frequency is key to increase the robustness of the tension clamp.

Innovative geometry

Pandrol SD-E innovative geometry increase the contact area between clip and rail and solves ballast entrapment problem of SKL tension clamps.

Innovative geometry

Pandrol SD-RE innovative geometry increase the contact area between clip and rail and solves ballast entrapment problem of SKL tension clamps.

Other products in the range

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.