Aluminothermic Welding

With more than a century of railway line welding experience, Pandrol is a global company you can trust to provide industry-leading aluminothermic welding solutions and a range of innovative and patented rail welding products. We make railway track welding safer, smarter and more efficient.

What is Aluminothermic Welding?

Aluminothermic welding is a vital part of building and maintaining railway infrastructure. It is a highly skilled and technical process. Ultimately, the safety and well-being of your passengers depend on the integrity of the welds that join or extend your rail track.

- Aluminothermic welding is a vital step in building railroad infrastructure, using an exothermic reaction to create liquid metal that joins and repairs rail.

- For more than a century, Pandrol has built on a wealth of practical experience to design and introduce new systems and welding technology to make aluminothermic welding safer, more efficient and reliable, and more cost-effective. Direct from our research and development labs we bring you a series of innovations that are changing the face of railway line welding.

- Read on to find out more about our latest product innovations and our specialist welding services designed for nearly all global rail profiles, and how we apply them to the aluminothermic welding process.

Download the catalogue

Our products

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

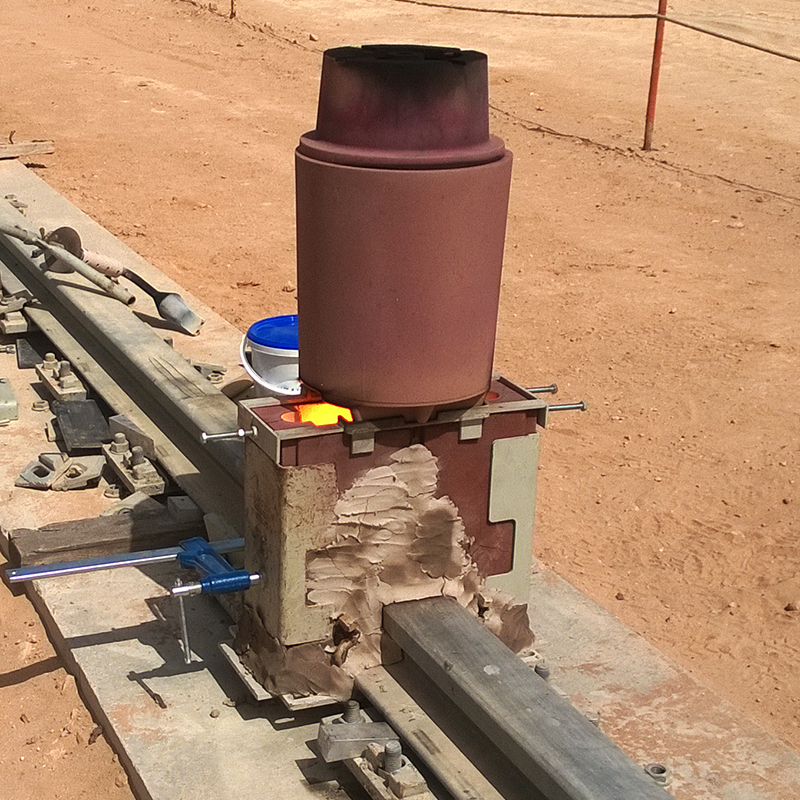

The process involves casting molten steel (produced through the reaction of iron oxide and aluminium) at a temperature exceeding 3,500 ˚F (1,950 °C) into refractory moulds designed to the rail specification.

Grooved Rail Welding

This flat-bottomed rail is typically larger and designed to continuously support high volumes of weight.

Crane Rail Welding

HWR is suitable for repairing railhead defects between 25mm and 90mm wide and 25mm deep (depending on the rail profile), it can be used on both the parent rail and on electric flash butt welds, which often suffer from squats. It is also suitable for transversal defects, shelling and corner gauge. The aluminothermic weld process is carried out using specially designed moulds.

Head Wash Repair Rail Welding

Beyond offering welding processes for all standard rail profiles, we also collaborate with customers to engineer bespoke solutions for special rail types that are less commonly used, such as the special rail grades used on metro lines including rubber-tyred rail, guide bar rail, conductor rail, and rack rail. We can offer portions, moulds and crucibles designed to your exact specification.

Special Rail Welding

AutoSeal® moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly AutoSeal®)

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

The ignition system is engineered to fit precisely into the round opening in the lid of the Pandrol Crucible. Once the crucible is prepped and ready to pour, the Startwel® Ignition System can be placed in the lid and deployed safely by removing the metal clip grounding the prongs.

Startwel® Ignition System

Pandrol Connect consists of three modules: a mobile version for welders to record on-site data and for welding controllers to review data, an online monitoring app to review weld information from the office, and an online administration tool to apply settings to local standards.

Pandrol Connect Welding App

The WEL-D’STRESS® system introduces residual stresses of compression and prevents the appearance of fatigue stains when traffic is intense.

WEL-D’STRESS® Hammer

Why do welders use the Pandrol process?

With more than 100 years of experience, we have a refined range of processes suitable for all global rail profiles. Our proven track record of results extends across all climates and terrains.

We provide a range of compact aluminothermic welding equipment to make the process even easier. Pandrol equipment is designed to offer maximum adaptability to different track configurations.

Pandrol is a team of 1700 employees spanning 30 global locations. That means our welding experts apply their track construction knowledge and product design expertise to your specific rail infrastructure requirements. When your teams need specialist training we can provide remote virtual, onsite, or headquarters-based training and certification.

Pandrol have created the world’s first self-sealing welding mould, streamlining the end-to-end aluminothermic welding process by up to five minutes per weld. Actively reduce plastic waste by choosing our more environmentally friendly solution.

Pandrol’s High Flow Preheater system is fully automated for easier, more reliable operation. It requires no manual interference or flame adjustment, and has been designed to withstand extreme track conditions and reduce maintenance costs.

Our Welding Research and Development department has adopted rapid digitisation and prototyping to digitally simulate solutions, allowing us to identify the cause of weld defects and reduce their frequency.

Understanding different types of rail welding

If you are part of the welding community, you will undoubtedly hear these terms thrown around often. But what are the practical differences between these types of welding, and what makes them unique?

Vignole rail is one of the oldest and most reliable common track types. It is flat-bottomed for simple and stable fixture to pads or sleepers. These rails are the most commonly used on mainline, high-speed, and heavy haul tracks across the globe. Vignole rail is flat-bottomed and slim-webbed.

Weld new and existing rail with Pandrol’s cutting-edge vignole rail welding process. Our approach is suitable for performing standard-gap and wide-gap welds on vignole rail. It can also be adapted to any dimensions of vignole rail.

Grooved rail is typically used on metro and tram systems. It is embedded in the ground to accommodate pedestrian and vehicular traffic. Grooved rails can be installed flush to pavements or grass. Unlike standard rails, they are bifurcated for added stability – consisting of a rail head on one side with a guard on the other.

Once installed, grooved rail can be challenging to weld due to the logistics involved – the concrete and rubber surrounding the rail must be removed before repairs, which is a time consuming task. Therefore, it is vital that grooved rail welds are cast to the highest possible quality.

Pandrol’s grooved rail welding solutions make life easier for the welder. Our specialist refractory moulds suit every grooved rail repair application. We adapt our techniques to accommodate global approaches. Trust our high-spec, internationally renowned welding portions, moulds, and crucibles to get the job done.

Crane rail is manufactured to accommodate heavy weight as it must support large axle loads of machinery. While visually similar to flat-bottomed rails such as vignole, crane rails are much heavier and have a thicker web for increased capacity and stability.

Their main use is in overhead gantry and floor-mounted equipment used to manoeuvre cranes in warehouses, shipyards, and port environments. Crane rails don’t typically sit on pads or sleepers. Instead they’re continuously supported.

Crane rails are often located in unique surroundings – so they require a specialist approach to welding for efficient and effective repair and maintenance. Trust Pandrol’s years of global expertise to tailor a bespoke welding solution for your crane rail needs.

Head Wash Repair welds are a cost-effective and efficient solution to repairing railhead defects without the need to cut the rail. The process involves grinding out the rail defect. A Head Wash Repair mould allows the remaining gap to be filled without the cutting and double-weld processes required for a plug rail repair.

Fix defects between 25mm and 90mm in width, and up to a depth of 25mm with Pandrol Head Wash welding. This rail maintenance style is much more efficient than a plug rail repair – requiring fewer welds, less time, and reduced cost.

Minimise maintenance costs while maintaining the highest quality of repairs by working with the world leaders in Head Wash Repair welding. We’ve demonstrated the value of our Head Wash Repair process throughout rail networks in the US and Canada since 2008, the UK since 2013, and France from 2015. Benefit from the site-specific refinements we apply to our approach to unique local rail profiles and network standards.

Pandrol Connect

Pandrol Connect is a mobile app designed to support aluminothermic welders through the weld process – capturing live data about the weld and improving the traceability of welds for contractors and rail network operators.

The Aluminothermic Welding Process

The Aluminothermic Welding process is the most streamlined method of joining steel rail sections in use in the rail industry today. Because the weld can be carried out in situ without dismantling the track, aluminothermic welding is the most efficient way to weld railroad tracks. It is reliable, effective and can be adapted to many situations.

It involves the use of a molten metal alloy, which when applied to the surfaces to be joined reacts exothermically with them and produces an extremely high temperature joint. This process is used for making repairs to cut or damaged rails and also for increasing rail lengths. All components for the aluminothermic welding process are supplied as powders or granules which means that they are relatively lightweight and portable.

- Before the welding process can start, the ends of the rails are cut to a specific measurement to create a gap and are then aligned. A refractory mould is then fastened around the gap – refractory means that the material is heat resistant.

- The rail ends then need to be preheated in order for a successful weld to be achieved. All surfaces must be cleaned thoroughly prior to preheating so that no foreign matter enters into contact with them during the welding.

- The rails are heated above their recrystallisation temperature, which ensures that they are free from residual stresses generated during rolling or heating processes.

- Once preheating is completed, a crucible is placed on top of the mould, containing the aluminothermic powder compounds. Once the crucible is ignited, the liquid metal pours down into the refractory moulds via a hole in the top.

- The metal fills the mould and any excess is discharged into a slag bowl. After a period of time allowing everything to cool, the excess metal is removed, and the rail is grinded to a smooth finish.