i+seal moulds (formerly autoseal)

Streamline the welding process with Pandrol’s newest aluminothermic welding innovation. Our AutoSeal® moulds are designed to seal welds safely and efficiently, with no need for luting sand or paste – unlike traditional methods of mould welding.

Pandrol AutoSeal® Welding Moulds Explained

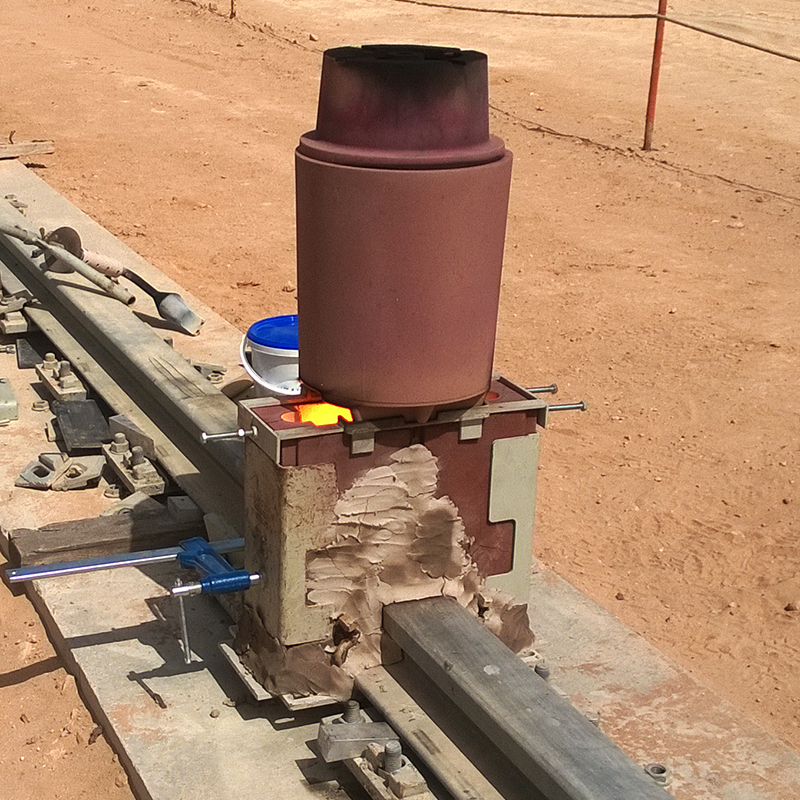

Aluminothermic mould welding traditionally involves luting – which seals the moulds to the rail ends with paste or sand to avoid metal leaks. AutoSeal® removes the need to do this while providing leak and moisture-free results. The built-in strip expands during the pre-heating phase to create a tight weld seal between the mould and rail. Benefits of this welding sealing method include speed, increased reliability, reduced waste and a more comfortable, less stressful process for the welder.

The new technology is compatible with vignole and groove rails and is recommended for the most demanding networks, meeting the needs of short possession times and high safety standards.

- Luting-free mould welding

- Seal welds faster and safer than traditional methods

- A leak-free welding sealing solution

Downloads

Advantages of using AutoSeal® Moulds

Time-saving

Save three to five minutes per weld with Pandrol’s AutoSeal® welding mould solution. The moulds seal automatically with their built-in expanding strip, removing any need for luting with sand or paste.

Safety and reliability

Guarantee welder safety. Pandrol AutoSeal® welding moulds have a self-sealing felt strip that is more reliable than manual luting sealing methods, preventing leaks and defects that could otherwise occur in cold weather and tight spaces.

Reduced defect rate

Ensure more consistent, high-quality results for your rail welds with AutoSeal® moulds, which are designed to reduce the defect rate by facilitating moisture evacuation during the preheating process.

Environmentally-friendly

Reduce plastic waste and improve your site’s carbon footprint. AutoSeal® moulds reduce the amount of energy needed for the production and transportation of aluminothermic welding materials for a more environmentally friendly solution.

Versatility

Choose welding moulds that are suitable for a range of applications. Our self-sealing weld moulds are compatible with vignole and grooved rails for convenience and multi-site use.

Technical Capabilities of AutoSeal® Moulds

Automatic sealing

Create a tight, leak-free seal between the mould and the rail with AutoSeal® moulds’ built-in expansive strip, which automatically expands in response to heat during the preheating phase of the aluminothermic weld.

Felted mould

Eliminate the need to manually grind the mould against the rail during set-up for the perfect fit. The AutoSeal® mould is equipped with compressive felt to perfectly fit the rail profile, providing precise, leak-free performance.

Moisture escape

Eliminate the need to manually grind the mould against the rail during set-up for the perfect fit. The AutoSeal® mould is equipped with compressive felt to perfectly fit the rail profile, providing precise, leak-free performance.

Compatible with worn rails

Complete weld repair or replacement on rails with up to 3mm of wear with the standard configuration of AutoSeal® mould. Welding up to 6mm wear or more is also possible with an adapted procedure.

Related products

Tested and approved against the European Standard EN 14730-1 Norm, the PLA Evo delivers improved metallurgical and mechanical behaviour, to optimise quality, lengthen the life of the weld and save time for the welder.

PLA Evo

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

HWR is suitable for repairing railhead defects between 25mm and 90mm wide and 25mm deep (depending on the rail profile), it can be used on both the parent rail and on electric flash butt welds, which often suffer from squats. It is also suitable for transversal defects, shelling and corner gauge. The aluminothermic weld process is carried out using specially designed moulds.

Head Wash Repair Rail Welding

Beyond offering welding processes for all standard rail profiles, we also collaborate with customers to engineer bespoke solutions for special rail types that are less commonly used, such as the special rail grades used on metro lines including rubber-tyred rail, guide bar rail, conductor rail, and rack rail. We can offer portions, moulds and crucibles designed to your exact specification.

Special Rail Welding

The process involves casting molten steel (produced through the reaction of iron oxide and aluminium) at a temperature exceeding 3,500 ˚F (1,950 °C) into refractory moulds designed to the rail specification.

Grooved Rail Welding

This flat-bottomed rail is typically larger and designed to continuously support high volumes of weight.

Crane Rail Welding

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

Pandrol Connect consists of three modules: a mobile version for welders to record on-site data and for welding controllers to review data, an online monitoring app to review weld information from the office, and an online administration tool to apply settings to local standards.

Pandrol Connect Welding App

The ignition system is engineered to fit precisely into the round opening in the lid of the Pandrol Crucible. Once the crucible is prepped and ready to pour, the Startwel® Ignition System can be placed in the lid and deployed safely by removing the metal clip grounding the prongs.