High Flow Preheater 36V

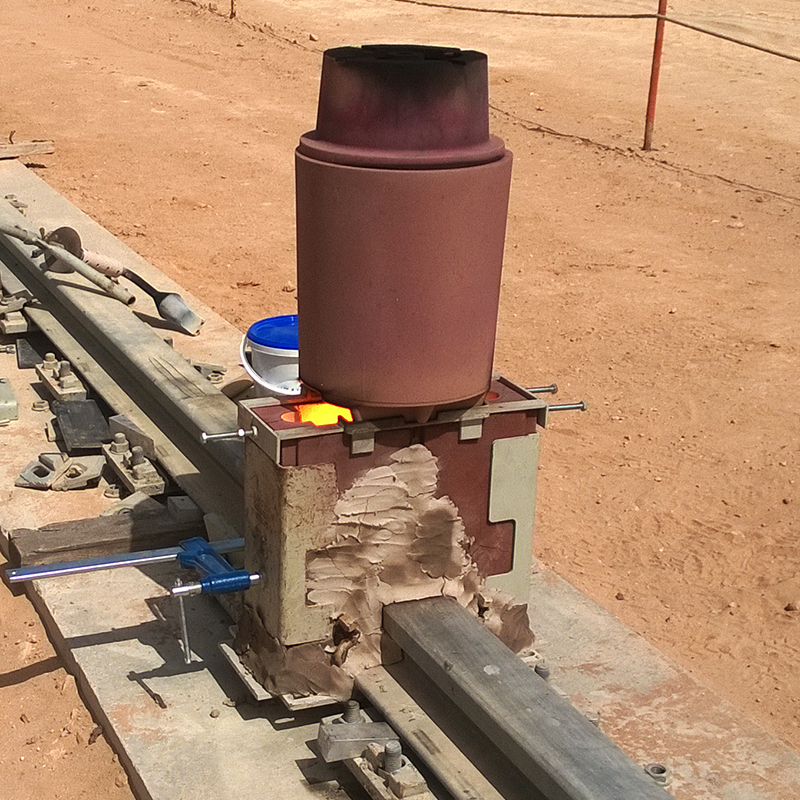

Achieve the perfect preheat temperature for welding every time, with the Pandrol High Flow Preheater 36V. Unlike other welding preheaters, Pandrol’s HFP 36V is battery-powered and fully automated for simpler, more reliable operation, requiring no manual interference or flame adjustment.

Pandrol High Flow Preheater Explained

Preheating before welding is an essential process that drives moisture out of the weld area and ensures a more consistent and robust end result.

The Pandrol High Flow Preheater 36V provides a complete, automated preheat welding procedure that is functional and versatile. It can replace most existing manual welding preheat equipment for simpler, faster, and safer operation.

A robust, high-performance solution, the HFP 36V is designed to withstand the most extreme track conditions, yet is still compact and light enough for single-person operation.

- A fully automated weld preheating process

- Propane-powered for performance and safety

- Compact, light and robust

Downloads

Advantages of the Pandrol High Flow Preheater (36V)

Accuracy and uniformity

Ensure uniform weld preheating every time with the HFP 36V’s built-in timer. Accurate pre-heat timing improves resulting weld quality and reduces the chance of weld stress and defects.

Automation

Speed up the preheating procedure for welding with the HFP 36V’s automated ignition, timing, and stop. With no need for manual interference or flame adjustment, less training is required. It’s easy for new welders to achieve the correct welding preheat temperature.

Portability

Save on transport costs and free up your welders to focus on their area of expertise. Unlike other preheating methods for welding, the HFP 36V uses propane power rather than oxygen, reducing costs and keeping the equipment lightweight for ease of use and transport.

Low maintenance needs

Keep daily operations running without interruption, with virtually maintenance-free welding preheat equipment. Thanks to its automated features, the Pandrol High Flow Preheater 36V does not require any specific regular upkeep.

Compact build

Reduce the labour needs of your welding project with the High Flow Preheater 36V’s compact size. With dimensions of 740mm x 300mm x 295mm and a light weight of just 19kg, the HFP can be easily handled by only one person.

Safety

Boost your site’s safety by switching to the Pandrol High Flow Preheater 36V. As an exclusively propane-powered welding preheating solution, it poses significantly less risk of accident or injury than traditional oxy-propane preheating equipment.

Technical Capabilities of the High Flow Preheater (36V)

Pressure adjustment tolerance

Ensure a uniform preheat between the head and the bottom of the rail for more consistent weld results. The preheat technology used by the HFP is less sensitive to pressure adjustment than oxy-propane.

Pre-set timing

Pre-set for accurate weld preheating time every time. Unlike some welding preheat equipment options, Pandrol’s 36V HFP comes with a built-in timer for enhanced accuracy with every use.

Fully automated operation

Eliminate the need for manual flame adjustment with the High Flow Preheater 36V’s automatic ignition, built-in timer, and automatic stop – designed for enhanced convenience, efficiency, and safety.

LiHD battery

Carry out up to eight to ten preheats – depending on the welding process used – on the High Flow Preheater’s two long-lasting 18V batteries with 8.0Ah. This reduces equipment downtime and keeps your welding project running with minimal interruptions.

Propane operation

Save money and reduce the overall weight of welding equipment by preheating welds with the HFP system. Its propane fuel makes it ultra-lightweight and cheaper to operate.

Single torch height

Choose welding preheat equipment that requires no adjustment. The Pandrol High Flow Preheater 36V has a single torch height compatible with all welds, so can be used across projects.

2 batteries of 18 V, 8.0 Ah.

Connect propane inlet.

Screen to control time.

Related products

Tested and approved against the European Standard EN 14730-1 Norm, the PLA Evo delivers improved metallurgical and mechanical behaviour, to optimise quality, lengthen the life of the weld and save time for the welder.

PLA Evo

AutoSeal® moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly AutoSeal®)

HWR is suitable for repairing railhead defects between 25mm and 90mm wide and 25mm deep (depending on the rail profile), it can be used on both the parent rail and on electric flash butt welds, which often suffer from squats. It is also suitable for transversal defects, shelling and corner gauge. The aluminothermic weld process is carried out using specially designed moulds.

Head Wash Repair Rail Welding

Beyond offering welding processes for all standard rail profiles, we also collaborate with customers to engineer bespoke solutions for special rail types that are less commonly used, such as the special rail grades used on metro lines including rubber-tyred rail, guide bar rail, conductor rail, and rack rail. We can offer portions, moulds and crucibles designed to your exact specification.

Special Rail Welding

The process involves casting molten steel (produced through the reaction of iron oxide and aluminium) at a temperature exceeding 3,500 ˚F (1,950 °C) into refractory moulds designed to the rail specification.

Grooved Rail Welding

This flat-bottomed rail is typically larger and designed to continuously support high volumes of weight.

Crane Rail Welding

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

Pandrol Connect consists of three modules: a mobile version for welders to record on-site data and for welding controllers to review data, an online monitoring app to review weld information from the office, and an online administration tool to apply settings to local standards.

Pandrol Connect Welding App

The ignition system is engineered to fit precisely into the round opening in the lid of the Pandrol Crucible. Once the crucible is prepped and ready to pour, the Startwel® Ignition System can be placed in the lid and deployed safely by removing the metal clip grounding the prongs.