Head Wash Repair Rail Welding

Provide a cost-effective and efficient alternative to plug rail repairs with Pandrol’s head wash rail repair process. We’ve been adding value to US and Canadian rail networks with this process since 2008, in the UK since 2013, and in France since 2015. Join the global rail pioneers who are already leading the way to improved rail weld repairs with Pandrol.

Pandrol’s Head Wash Repair Welding Process Explained

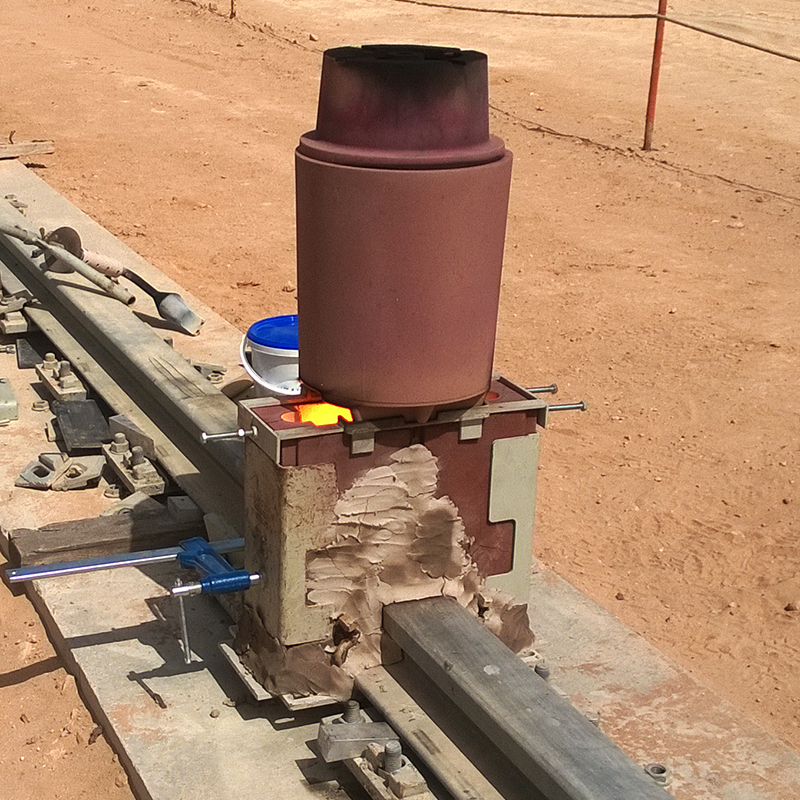

The aluminothermic head wash repair weld process is carried out using specially designed moulds. After unmoulding, the weld is trimmed and ground in accordance with the network specifications. It is capable of repairing railhead defects between 25mm and 90mm wide and 25mm deep (depending on the rail profile).

The head wash process can be used on both the parent rail and on electric flash butt welds, which often suffer from squats. It is also suitable for repairing transversal defects, shelling and corner gauges, and complies with the quality and safety requirements of all modern rail networks.

- Fast-track rail defect repairs with no need for destressing

- Comply with the quality and safety standards of your global rail network

- Choose a repair process that’s compatible with many weld types

Downloads

Advantages of the Pandrol Head Wash Repair Rail Welds

Simplicity

Repair head wash welds with just one weld and no need for rail destressing. The Pandrol head wash rail repair process is simple and efficient, bypassing the need for rail section replacement involved in the plug rail repair process.

Time savings

Save time compared to plug rail repair. The familiar mould design enables the welding crew to do the repair weld quickly and easily. Head wash repair welding takes just one hour rather than three or four, reducing rail system downtime and labour costs.

Safety

Promote a safer rail environment by choosing head wash repair rail welding. The process uses the same parameters and hardware as Pandrol’s signature aluminothermic welding process, which is known for its safety.

Equipment cost savings

Save the money you’d otherwise invest in training and hardware for alternative weld repair processes. The head wash weld repair process uses standard hardware and a one-shot crucible, making it easy for any welding expert to complete.

Compliance

Easily meet the compliance requirements of modern railway networks. Pandrol head wash repair welding is available for all rail grades and suitable for all environments.

Technical Capabilities of Head Wash Repair Rail Welding

Cutting and grinding

Adapt the head wash repair rail welding process to your project and equipment requirements. The slot can be created by oxy-propane cutting or grinding, as per your preference.

Optimum fusion area

Ensure total removal of the rail defect with head wash rail repair welding’s optimum size fusion area. The width is approximately 120mm with the oxy-propane cutting method, and 80mm with the grinding method. Fusion depth reaches 30mm below the slot.

Tensile stress management

Strengthen fatigue resistance while also avoiding flashing under the rail head for a cleaner weld. When using head wash repair rail welding, the felt protects this crucial location of the highest tensile stress.

Hardware

Choose a weld repair process that welding crews are already familiar with. The Pandrol head wash rail repair process uses standard hardware and a one-shot crucible, and its specially designed moulds are based on products that crews use often.

Versatility

Repair squats, transversal defects, shelling and corner gauge defects between 25mm and 90mm wide and 25 mm deep with the same process. Head wash repair is even compatible with the parent rail and electric flash butt welds.

Related products

Tested and approved against the European Standard EN 14730-1 Norm, the PLA Evo delivers improved metallurgical and mechanical behaviour, to optimise quality, lengthen the life of the weld and save time for the welder.

PLA Evo

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

i+seal moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly AutoSeal®)

Beyond offering welding processes for all standard rail profiles, we also collaborate with customers to engineer bespoke solutions for special rail types that are less commonly used, such as the special rail grades used on metro lines including rubber-tyred rail, guide bar rail, conductor rail, and rack rail. We can offer portions, moulds and crucibles designed to your exact specification.

Special Rail Welding

The process involves casting molten steel (produced through the reaction of iron oxide and aluminium) at a temperature exceeding 3,500 ˚F (1,950 °C) into refractory moulds designed to the rail specification.

Grooved Rail Welding

This flat-bottomed rail is typically larger and designed to continuously support high volumes of weight.

Crane Rail Welding

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

Pandrol Connect consists of three modules: a mobile version for welders to record on-site data and for welding controllers to review data, an online monitoring app to review weld information from the office, and an online administration tool to apply settings to local standards.

Pandrol Connect Welding App

The ignition system is engineered to fit precisely into the round opening in the lid of the Pandrol Crucible. Once the crucible is prepped and ready to pour, the Startwel® Ignition System can be placed in the lid and deployed safely by removing the metal clip grounding the prongs.