Pandrol Connect Explained

Record on-site data for welding controllers to review with Pandrol Connect, an online weld monitoring app designed for ease, efficiency, and ultimate traceability. The Pandrol Connect app consists of three modules, making recording, reviewing, and monitoring simple and accessible for welders, weld controllers, and administrators. Meet local standards with ease and share data simply thanks to the app’s cloud-hosted data storage.

- Support aluminothermic welders through the weld process

- Capture live data at speed

- Improve the traceability of welds for contractors and rail network operators

Downloads

Advantages of the Pandrol Connect Welding App

Increased weld traceability

Digitalise and enhance welding documentation for enhanced weld traceability. Pandrol Connect’s cloud-hosted data provides the transparency needed to easily identify weld and data anomalies for correction before, during and after welding.

More detailed records

Generate detailed records of your welding operations including the welder’s ID, geographic location, environmental factors, and various weld parameters with the Pandrol Connect Welding app.

Reduced carbon footprint

Weld apps like Pandrol Connect drastically cut down on paperwork thanks to their digitised, cloud data records, saving users time and improving your team’s environmental impact.

Adapt to welding best practices

Remain agile and respond to changes in industry best practices for welding operations with Pandrol Connect. The app includes a news function which keeps users up to date on developments and standards.

Cost-effective

Reduce time spent on paperwork with a cost-oriented solution. Unlike manual record-keeping, weld apps like Pandrol Connect require no capital outlay and make welds instantly traceable.

Technical Capabilities of the Pandrol Connect Welding App

Enhanced documentation capabilities

Use the Pandrol Connect welding app to document the location, environmental conditions, line type, and other weld-related geographic variables. Specify the rail profile, wear, alignment, gap, and cutting method used, as well as tracking timings and inspection results.

Operations tracking dashboard

Track your operations from your online dashboard. The Pandrol Connect App lets you review individual welds, synchronise and download data, and generate inspection certificates – all from a single platform.

Compatibility

Use the Pandrol Connect system across all your teams. Unlike some welding apps, Pandrol Connect is compatible with all welding kit suppliers for maximum versatility.

QR code integration

Scan all consumables used in your weld using the Pandrol Connect app’s QR code scanner, which automatically records the specific items used on-site to enhance records.

Welding instructions

Rely on the Pandrol Connect app’s detailed welding instruction manual, available right at every user’s fingertips for added support.

Works on track

Access weld information on site, even without internet access. Our welding app is a reliable reporting tool which uses an ergonomic interface specifically designed for use on track.

Designed for the full life cycle of the weld

Reload data for review at any point, and add additional information including profiling and inspection data to keep your weld records up to date.

Available for Android and iOS

Searching for welding apps for Android and iOS? Pandrol Connect is available for both, making it a versatile solution compatible with whatever devices your team prefers. Find it in the Google Play Store and Apple App Store.

Related products

Tested and approved against the European Standard EN 14730-1 Norm, the PLA Evo delivers improved metallurgical and mechanical behaviour, to optimise quality, lengthen the life of the weld and save time for the welder.

PLA Evo

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

i+seal moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly AutoSeal®)

HWR is suitable for repairing railhead defects between 25mm and 90mm wide and 25mm deep (depending on the rail profile), it can be used on both the parent rail and on electric flash butt welds, which often suffer from squats. It is also suitable for transversal defects, shelling and corner gauge. The aluminothermic weld process is carried out using specially designed moulds.

Head Wash Repair Rail Welding

Beyond offering welding processes for all standard rail profiles, we also collaborate with customers to engineer bespoke solutions for special rail types that are less commonly used, such as the special rail grades used on metro lines including rubber-tyred rail, guide bar rail, conductor rail, and rack rail. We can offer portions, moulds and crucibles designed to your exact specification.

Special Rail Welding

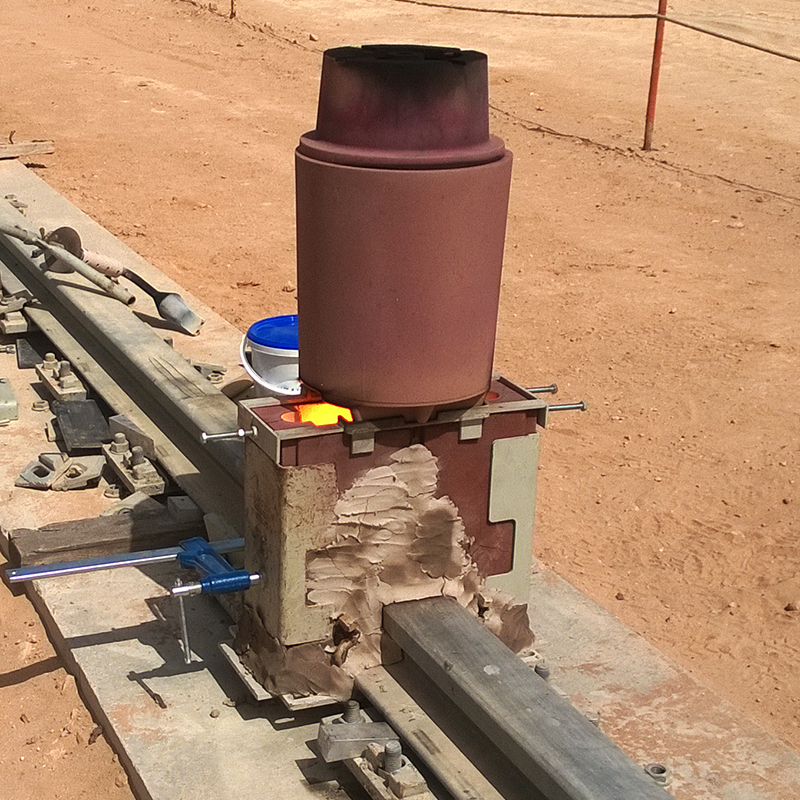

The process involves casting molten steel (produced through the reaction of iron oxide and aluminium) at a temperature exceeding 3,500 ˚F (1,950 °C) into refractory moulds designed to the rail specification.

Grooved Rail Welding

This flat-bottomed rail is typically larger and designed to continuously support high volumes of weight.

Crane Rail Welding

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

The ignition system is engineered to fit precisely into the round opening in the lid of the Pandrol Crucible. Once the crucible is prepped and ready to pour, the Startwel® Ignition System can be placed in the lid and deployed safely by removing the metal clip grounding the prongs.