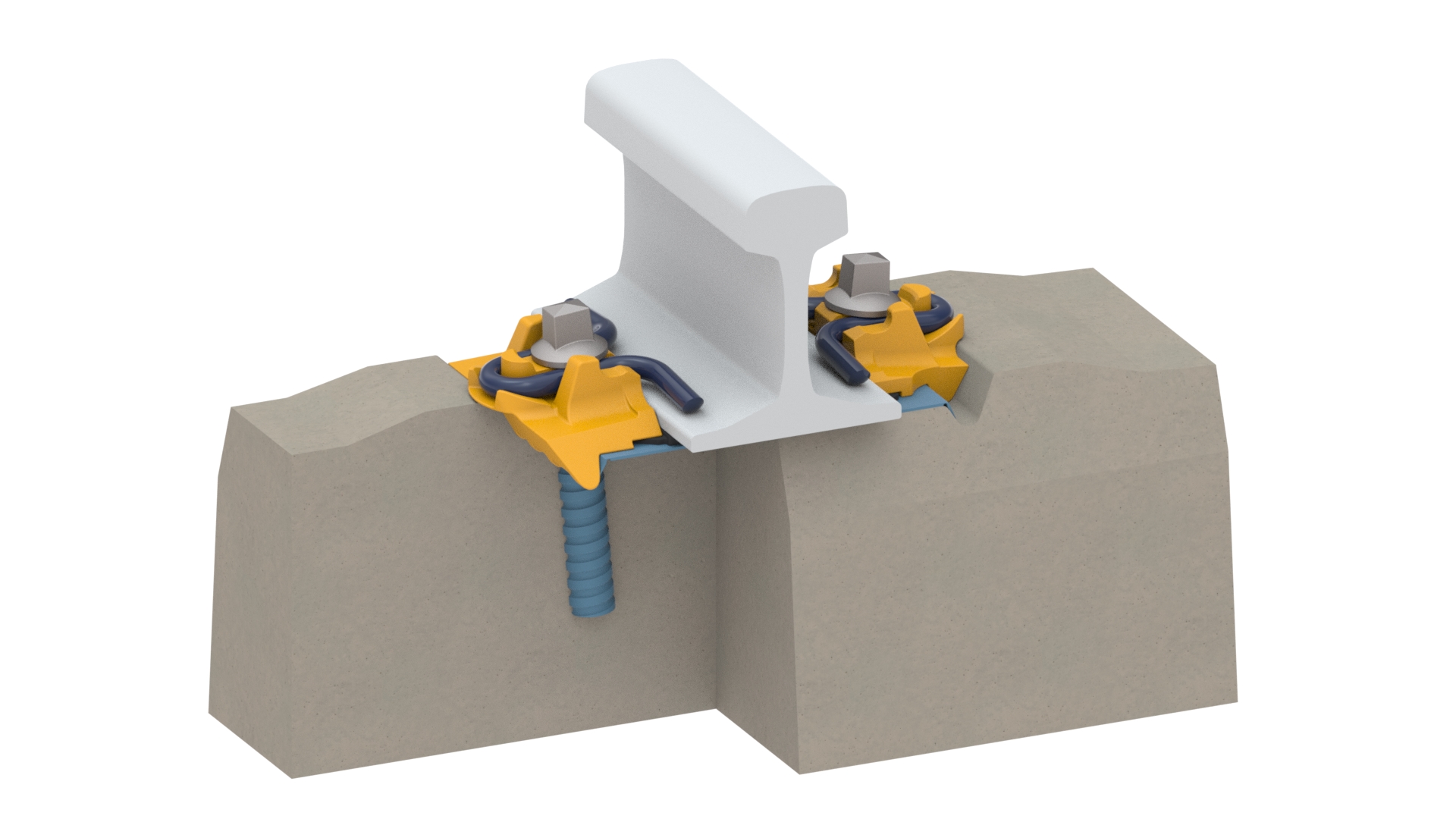

SD-HH product overview

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

- The SD-HH fastening system can be pre-assembled on the concrete sleeper or retrofitted to existing track infrastructure

- It is fully interchangeable on W14 sleeper profiles and can be used to replace Vossloh SKL fastenings, providing the opportunity for increased gauge widening.

Downloads

Benefits of the SD-HH

Multi-functional

Very high rates of track construction and maintenance can be achieved with SD-HH fastenings thanks to pre-assembly and the option of using mechanised equipment. This saves time, labour and distribution costs throughout the system’s lifecycle.

Versatile

Available in a range of different configurations and highly adjustable (both laterally and vertically), the SD-HH is a versatile solution that is suitable for most track infrastructure and meets a wide range of customer requirements for stiffness, adjustment, and rail clamping force.

Compatible

The SD-HH clip can be designed for use in small spaces such as turnouts, allowing customers to keep the same type of fastening throughout the track.

Low weight

Compared to similar products, the clip is relatively low weight. This reduces its environmental impact without compromising on performance.

Protects

The fastening system has been designed to protect the sleeper from abrasion.

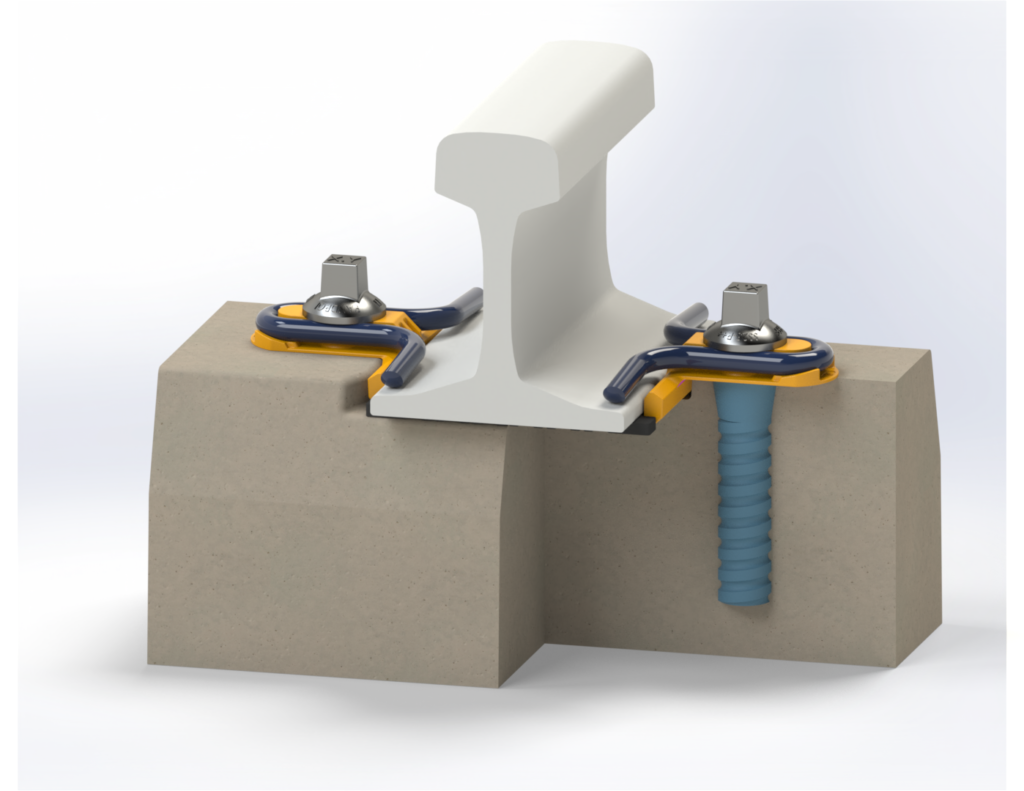

Widening Option

The SD-HH can provide a simple retrofit upgrade for Vossloh SKL fastenings, offering a gauge widening option of up to +15mm (compared to SKL’s +8mm).

Technical features of SD-HH

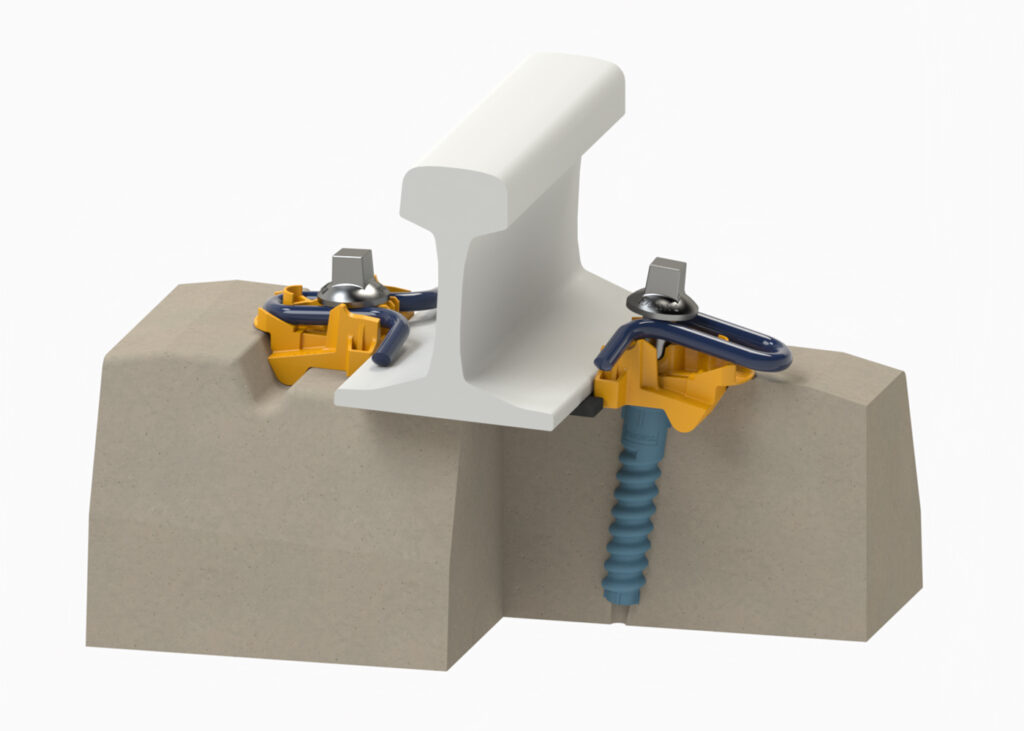

Captive fastening

SD-HH sleepers can be supplied fully pre-assembled to construction sites, with all components remaining captive during construction and maintenance activities.

Clamping force

The high elasticity of the SD-HH clip ensures the correct clamping force. As a result, a consistent longitudinal restraint is achieved automatically when screws are tightened until full contact is made.

Gauge adjustment

Accurate lateral rail adjustment is achieved by changing the guide plate insulators for different sizes in required increments, by steps of 2.5mm.

Track-structure interaction

The SD-HH clip is available in low toe load and a zero longitudinal restraint (ZLR) configuration, typically for use on bridges and viaducts when track-structure interaction effects need to be dealt with in the rail fastening assembly.

SKL conversion

SD-HH can be installed in an SKL-shaped rail seat, providing a simple retrofit upgrade.

Other products in the range

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

SD-E is the lightest version of the SD product family (up to 40% weight reduction).