DRS Baseplate product overview

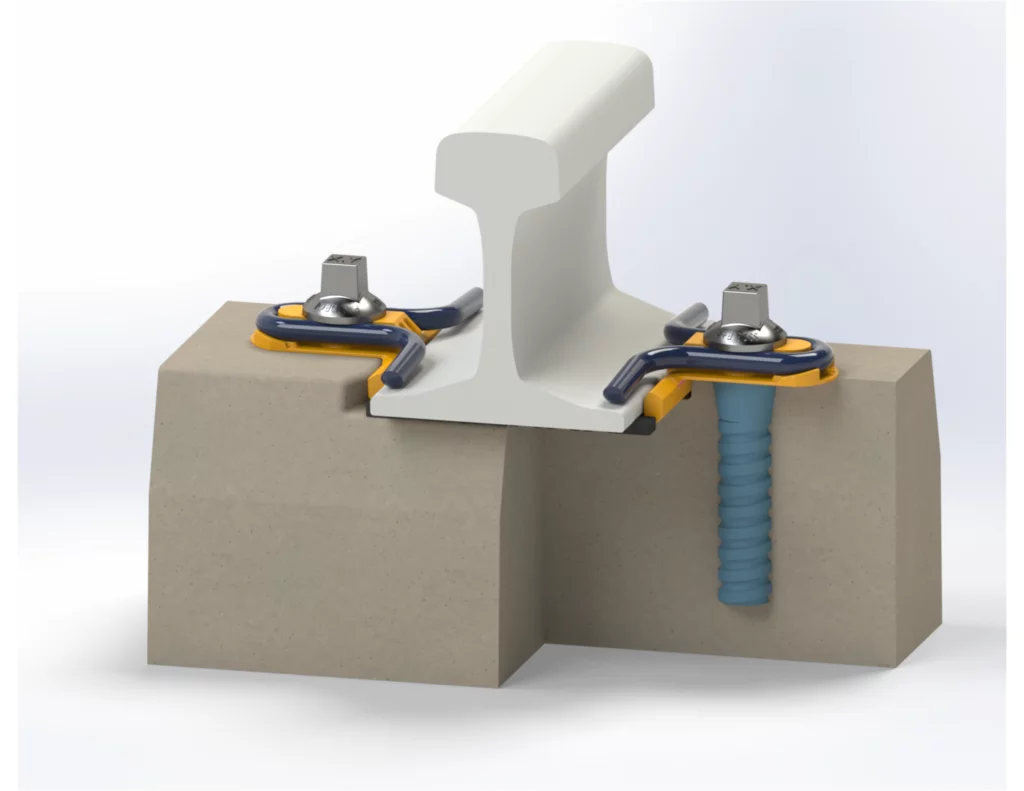

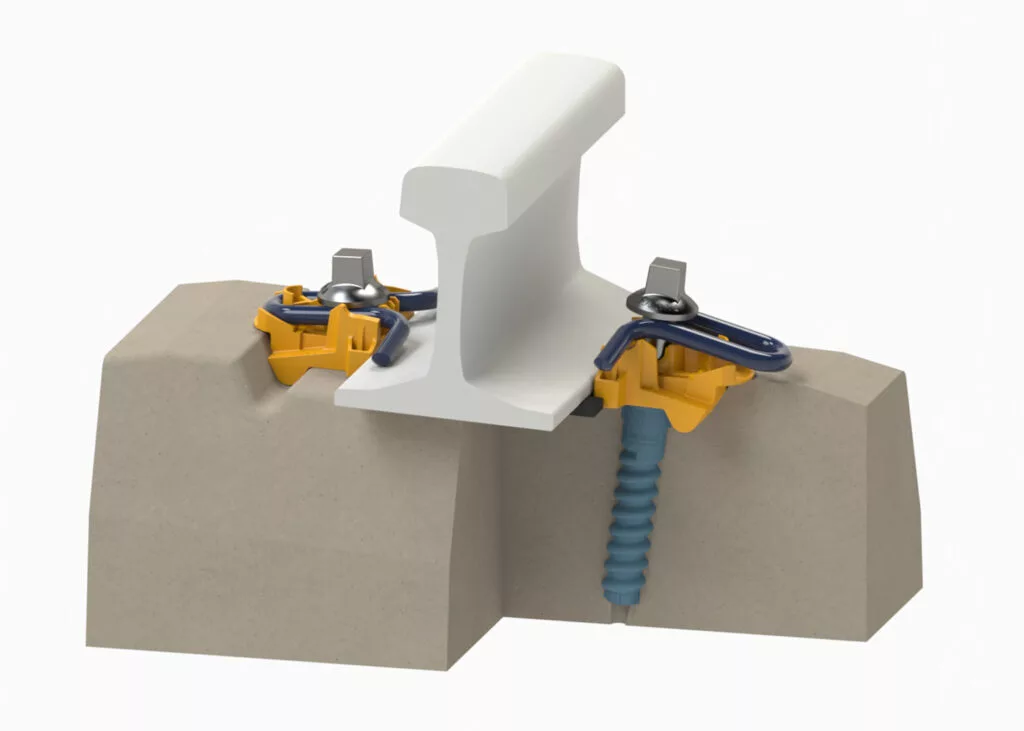

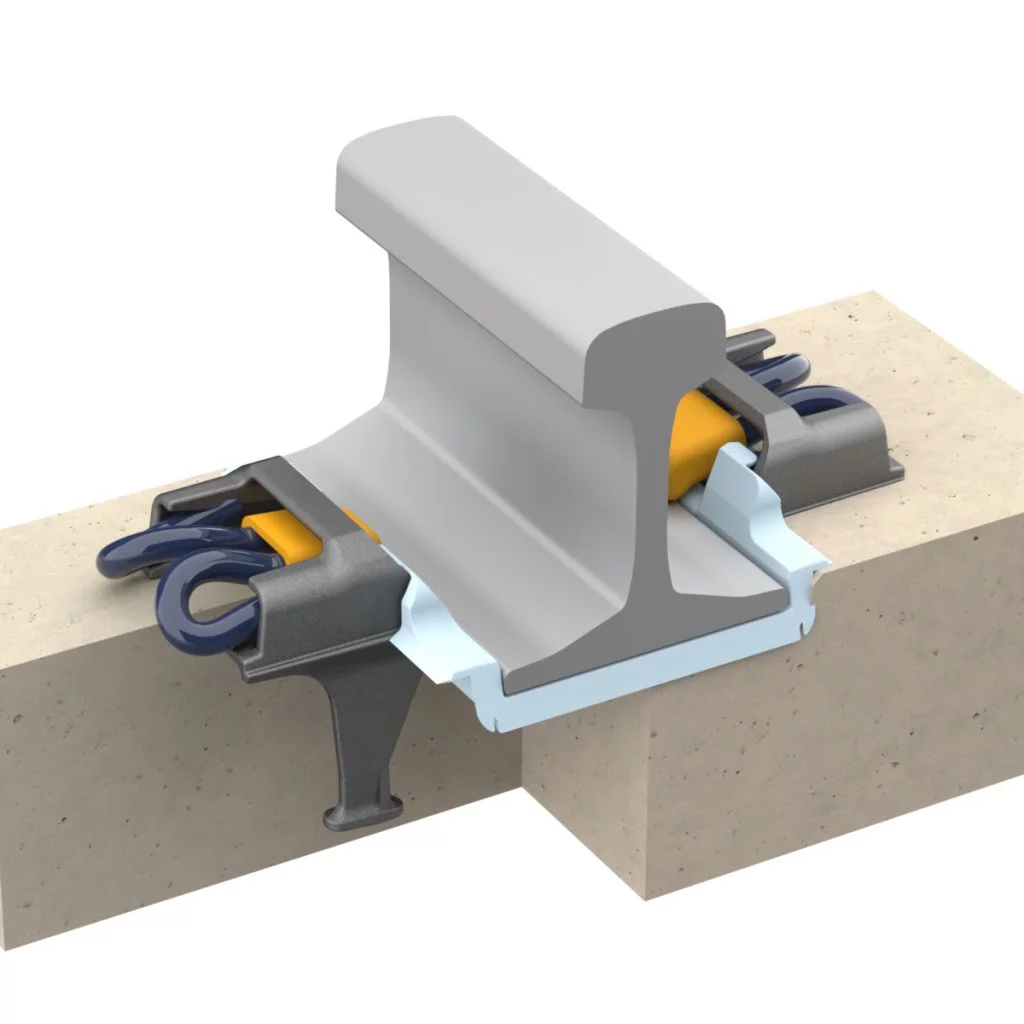

Originally introduced in the 1980s, today’s evolution of the DRS baseplate is the trusted solution for metro, light rail and mainline slab tracks worldwide.

- Widely used on bridges, viaducts and in tunnels, it is suitable for all rail inclinations and rail types.

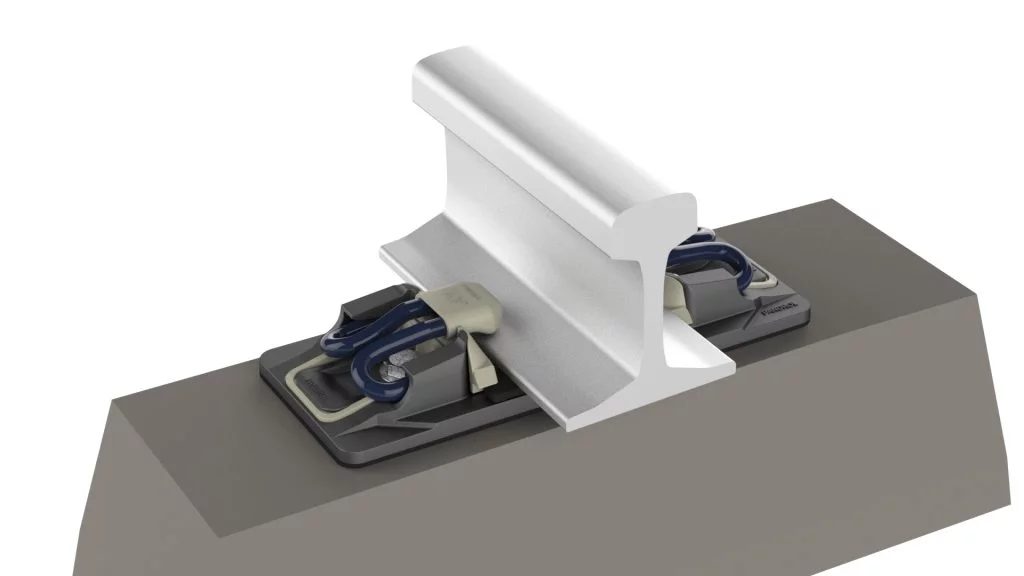

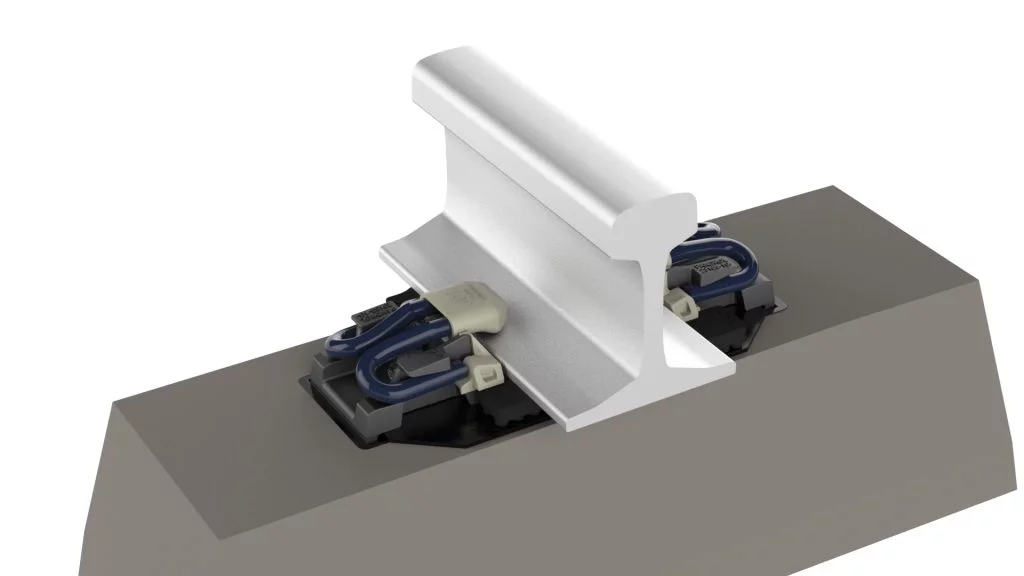

- The DRS baseplate is mounted on a studded, natural rubber pad that can be tuned for different axle loads and stiffness requirements.

- With a threadless fastening system and parts that can be replaced in situ, the baseplate requires minimal maintenance.

- Formerly known as VIPA DRS.

Downloads

Advantages of using Pandrol DRS Baseplate

Versatile

The DRS baseplate is adjustable, can be installed in different ways and is available in a range of configurations, making it a versatile option for all non-ballasted tracks and rail types.

New or Renew

Its versatility also means that it is the ideal solution for new-build tracks, renews and retrofit applications.

Less Vibration

The resilience provided by the baseplate’s rubber pad mitigates the effects of ground-borne vibration and secondary noise.

Insulated

High levels of electrical insulation increase the product’s efficiency and cost-effectiveness.

Compact

The compact footprint provided by the 2-hole baseplate reduces the size of pre-cast concrete elements required.

Technical features of the Pandrol Fastclip

Variable baseplate options

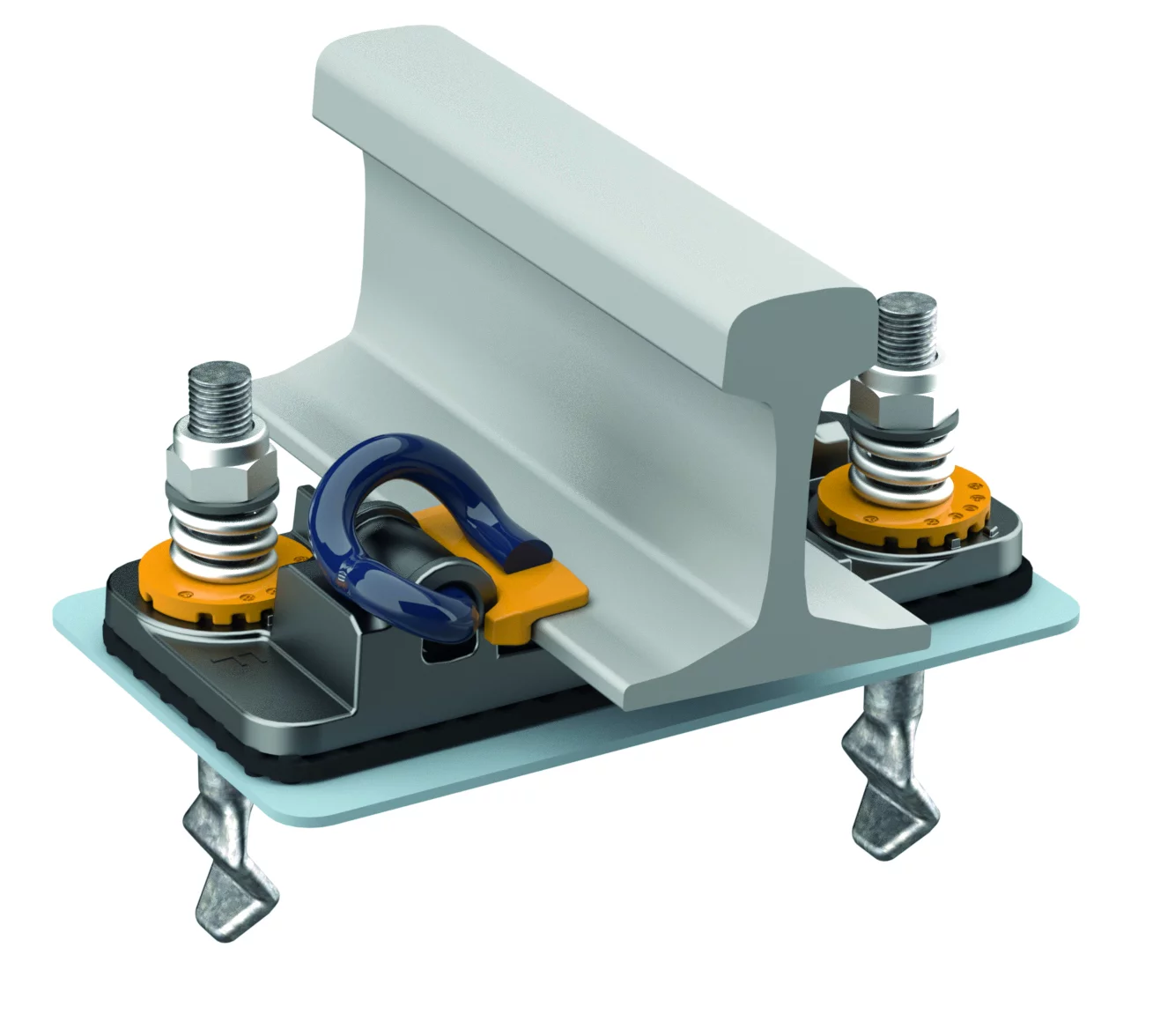

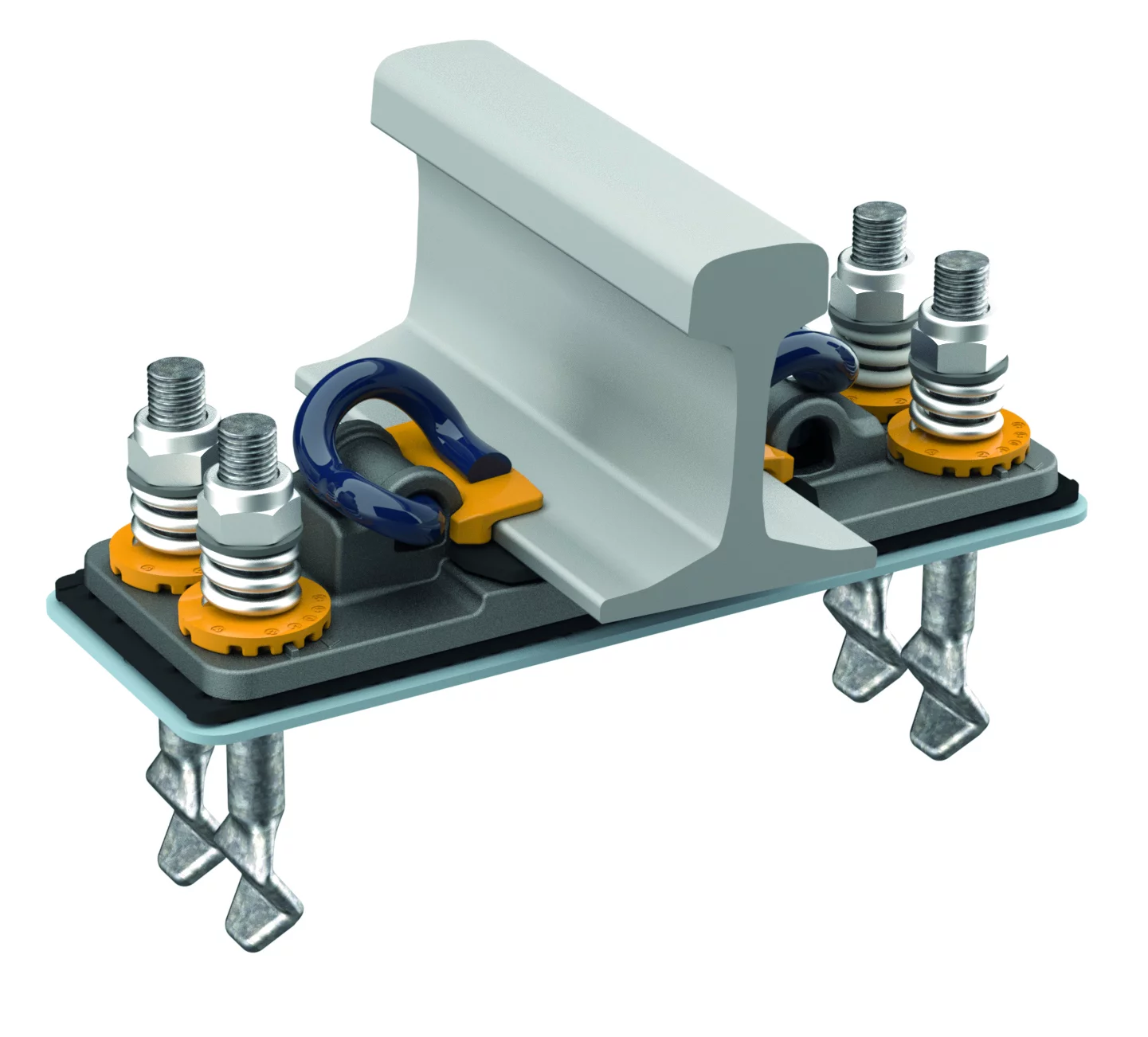

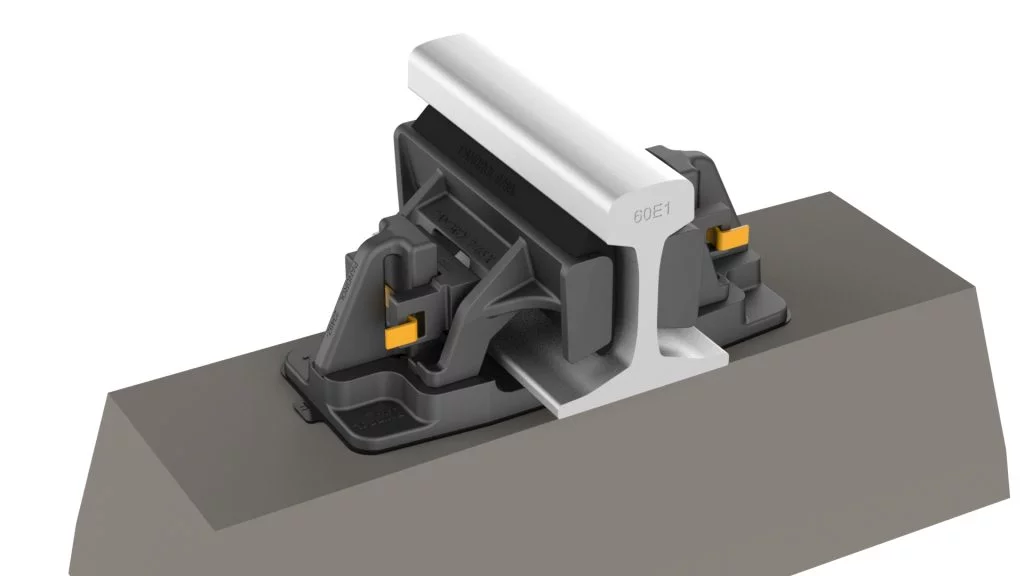

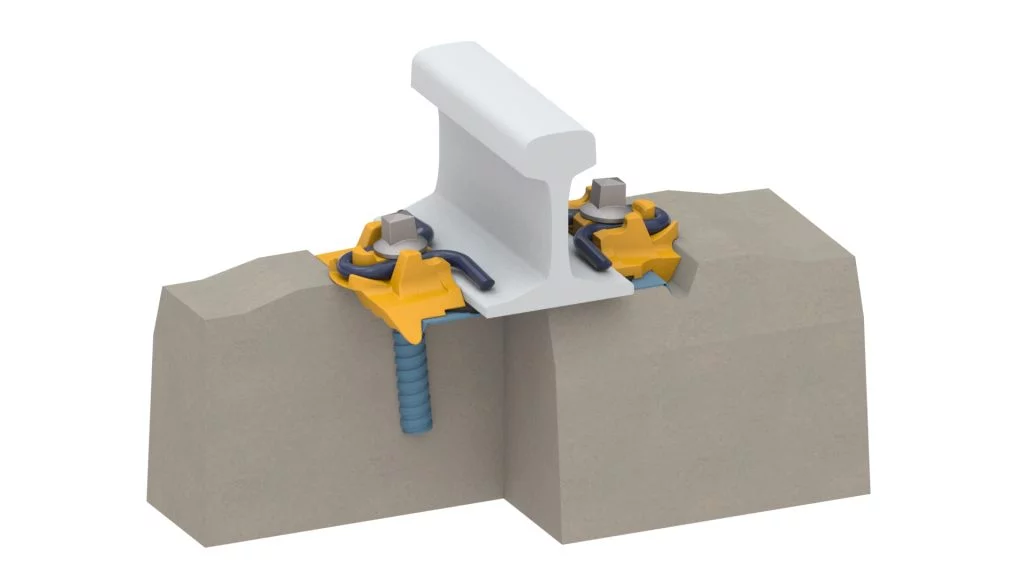

The DRS system is available with different baseplate configurations: a 2-hole offset footprint and a 4-hole inline.

Compact footprint

The 2-hole DRS baseplate provides a very compact footprint.

Electrical insulation

The baseplate system provides an exceptionally high level of electrical insulation, with the rail insulated from the baseplate and the baseplate insulated from the concrete slab.

Adjustability

The DRS baseplate achieves typical lateral adjustment of +/-5mm, with additional adjustability possible to meet specific requirements. Typical vertical adjustment of up to 12mm can be achieved with shims.

Track structure interaction

Rail fastening clips for the DRS baseplate are available in low toe load and a zero longitudinal restraint (ZLR) configuration to deal with the effects of track structure interaction.

DRS Baseplate - 2 Hole

DRS Baseplate - 4 Hole

Related products

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip

Vortok Coil

The rail seat assembly is typically made up of two tension clamps (SKL clips) on top of angled guide plates on each side of the rail.