Shoulder Clearance Safety Barrier product overview

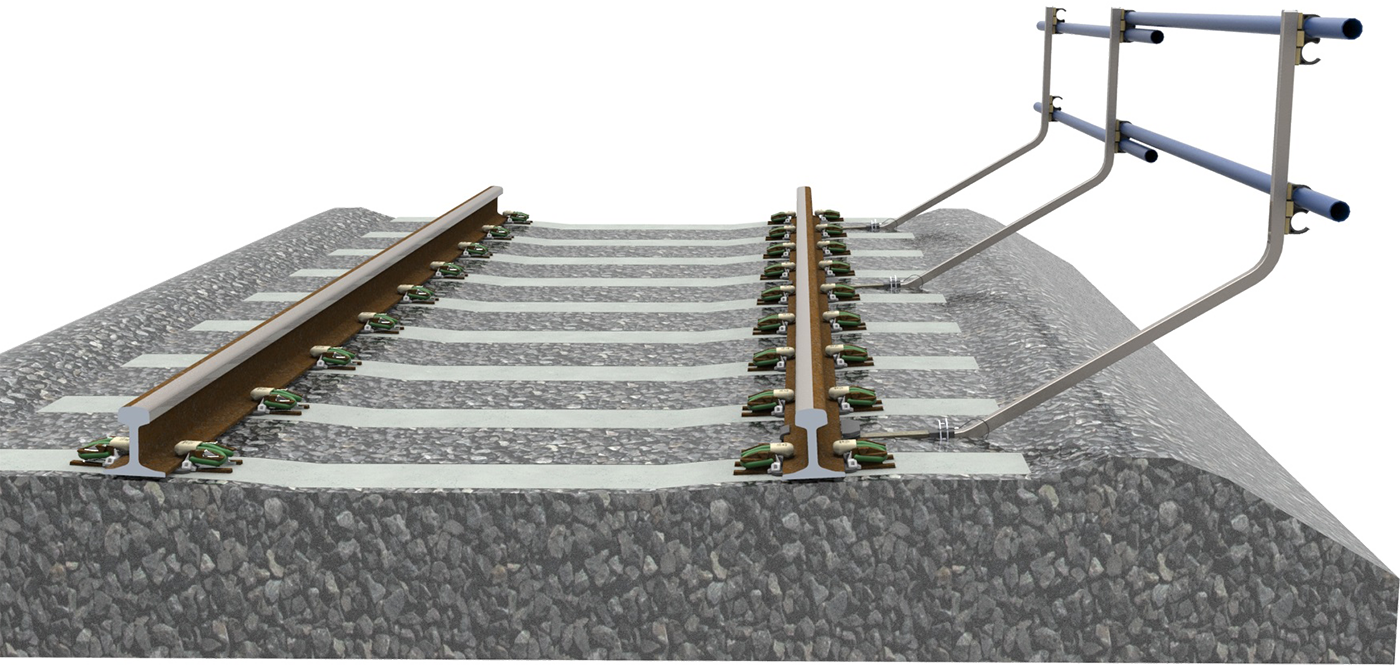

The Shoulder Clearance Safety Barrier is designed to clear a high ballast shoulder, it is clamped to the rail foot of the live traffic line with minimal ballast disturbance.

- It has insulation properties, giving protection in overhead line environments

- The Shoulder Clearance Safety Barrier fits virtually all rail types and is widely used in many countries, including the UK, Germany, Australia, Belgium, Sweden and Norway

- It is the UK industry standard for track working protection and has won the Alstom Award for Innovation

Downloads

Benefits of the Shoulder Clearance Safety Barrier

Enhanced safety

The Shoulder Clearance Safety Barrier improves track safety by providing a physical barrier that prevents workers accidentally entering the live traffic area.

Adaptable

The barrier is ideal for use where there is a high ballast shoulder.

Accessible

Workers caught on the wrong side of the safety barrier can easily re-enter the safe zone.

Money saving

The barrier enables higher train running speeds on adjacent lines, resulting in significant cost savings thanks to fewer train delay penalties.

Efficient installation

Installation is fast and efficient, with no need for specialist tools or equipment. There is no disturbance of the ballast shoulder.

Technical features of Shoulder Clearance Safety Barrier

Installed by clamping

The Shoulder Clearance Safety Barrier arm is clamped to the rail foot of the live traffic line. The clamp spacing is approximately 2.5 to 2.7 metres.

Ease of installation

No tools are required to install the barrier and the process of clamping it to the rail foot is quick and easy.

High ballast shoulder clearance

The barrier arm has been designed to clear a high ballast shoulder. The non-telescopic barrier is set at 4-foot (1.25m) from the running rail.

Insulation

The barrier has insulating properties, providing protection in overhead line environments.

Reusable components

All components are fully reusable and are supplied in their own storage stillages, convenient for transporting.

Compatibility

The Shoulder Clearance Safety Barrier has been designed for compatibility with flat-bottomed rail profiles.

Track lighting

Track lighting can be attached to the barrier using the Network Rail approved Lightmast Bracket.