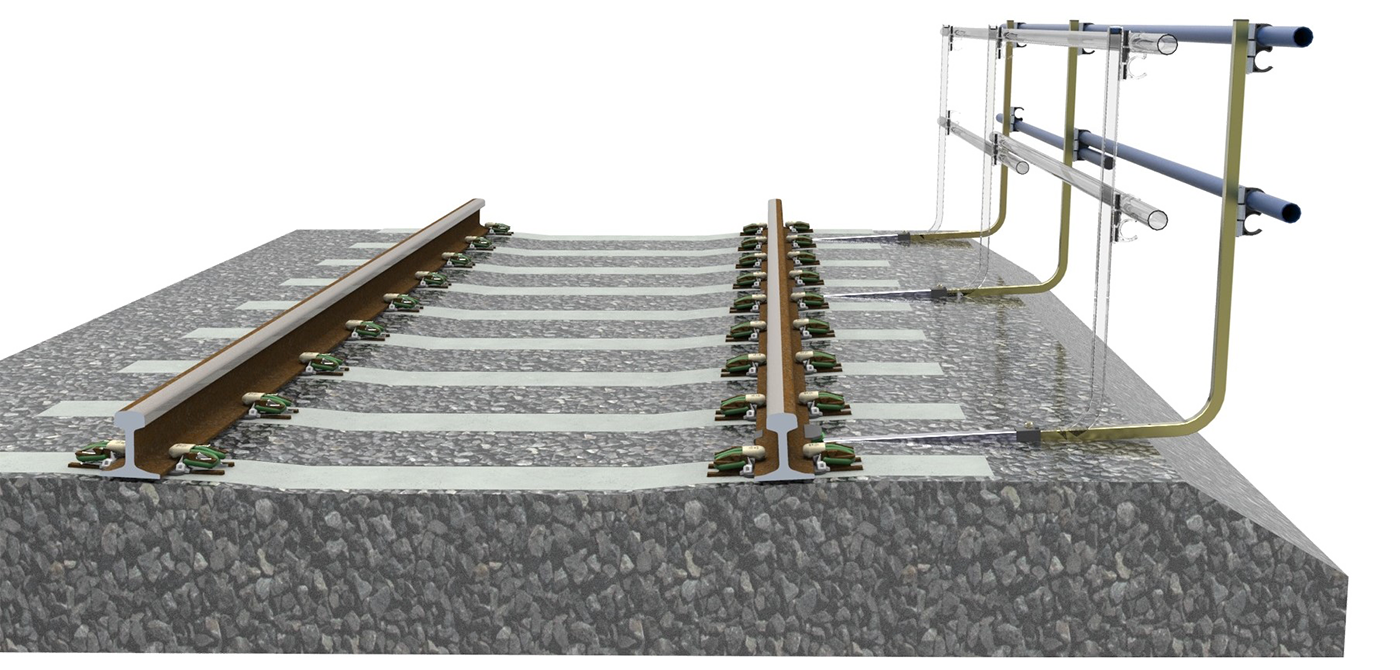

Pandrol Telescopic Safety Barrier Explained

Pandrol understands that site safety is a top priority for rail operators worldwide. Our Telescopic Safety Barrier is designed to drive up international rail safety standards.

The Pandrol Telescopic Safety Barrier has been engineered for varying line speeds, maximising its versatility. The barrier is clamped to the rail foot of the live traffic line and has insulation properties, giving protection in overhead line and third rail environments. The product is compatible with virtually all rail types and is widely used in many countries including the UK, Germany, Australia, Belgium, Sweden, and Norway.

In the UK, the Pandrol Telescopic Safety Barrier sets the industry standard for track working protection and holds a 2002 Alstom Award for Innovation and Safety.

- Setting the UK industry standard for track worker protection

- Engineered for varying line speeds

- Winner of an Alstom Award for Innovation and Safety

Downloads

Advantages of the Pandrol Telescopic Safety Barrier

Enhanced safety

Provide a physical barrier between workers and the live traffic area of your rail system with the Telescopic Safety Barrier, which is proven to improve site safety.

Versatility and accessibility

Rely on the Pandrol Telescopic Safety Barrier for high performance on tracks with any line speed. Workers caught on the wrong side of the safety barrier can easily re-enter the safety zone, preventing accidents.

Cost savings

Cut costs while maintaining excellent safety. The Telescopic Safety Barrier enables higher train running speeds in adjacent lines, meaning essential repair works can happen with fewer delay penalties.

Efficiency

No specialist tools or equipment are required to install the Pandrol Telescopic Safety Barrier in your rail environment, making installation fast and efficient, so your team can speed up repairs and maintenance and reduce track downtime.

Technical features of Pandrol’s Telescopic Safety Barrier

Adjustable rail

Adjust the Telescopic Safety Barrier to the line speed of your rail system. The product offers adjustability from 1.25 m (4’) to 2.0m (6’6”).

Clamped installation

Install the Telescopic Safety Barrier safely and quickly. No buried services scan is required as the barrier arm clamps directly to the rail foot of the live traffic line. The clamp spacing is approximately 2.5 to 2.7 metres.

Insulation

Create a working environment safe from electrical hazards with the Pandrol Telescopic Safety Barrier’s insulating properties. The barrier provides protection in overhead line and third rail environments.

Reusable components

Save on replacement and transport costs. The Telescopic Safety Barrier’s components are fully reusable and supplied in their own storage stillages for the ultimate convenience.

Compatibility

Apply the Telescopic Safety Barrier to any rail system thanks to its compatibility with flat-bottomed, bull-head, and third rail areas. It is Network Rail-approved for AC, DC, and non-electrified tracks, plus all train speeds.

Track lighting

Attach track lighting to the Telescopic Safety Barrier using the Network Rail-approved Lightmast Bracket, so work can be carried out at night or in low-light settings.

Related products

For welding to take place in wet and windy weather, adequate protection is needed.

Track Welding Tent

The Shoulder Clearance Safety Barrier is designed to clear a high ballast shoulder, it is clamped to the rail foot of the live traffic line with minimal ballast disturbance.