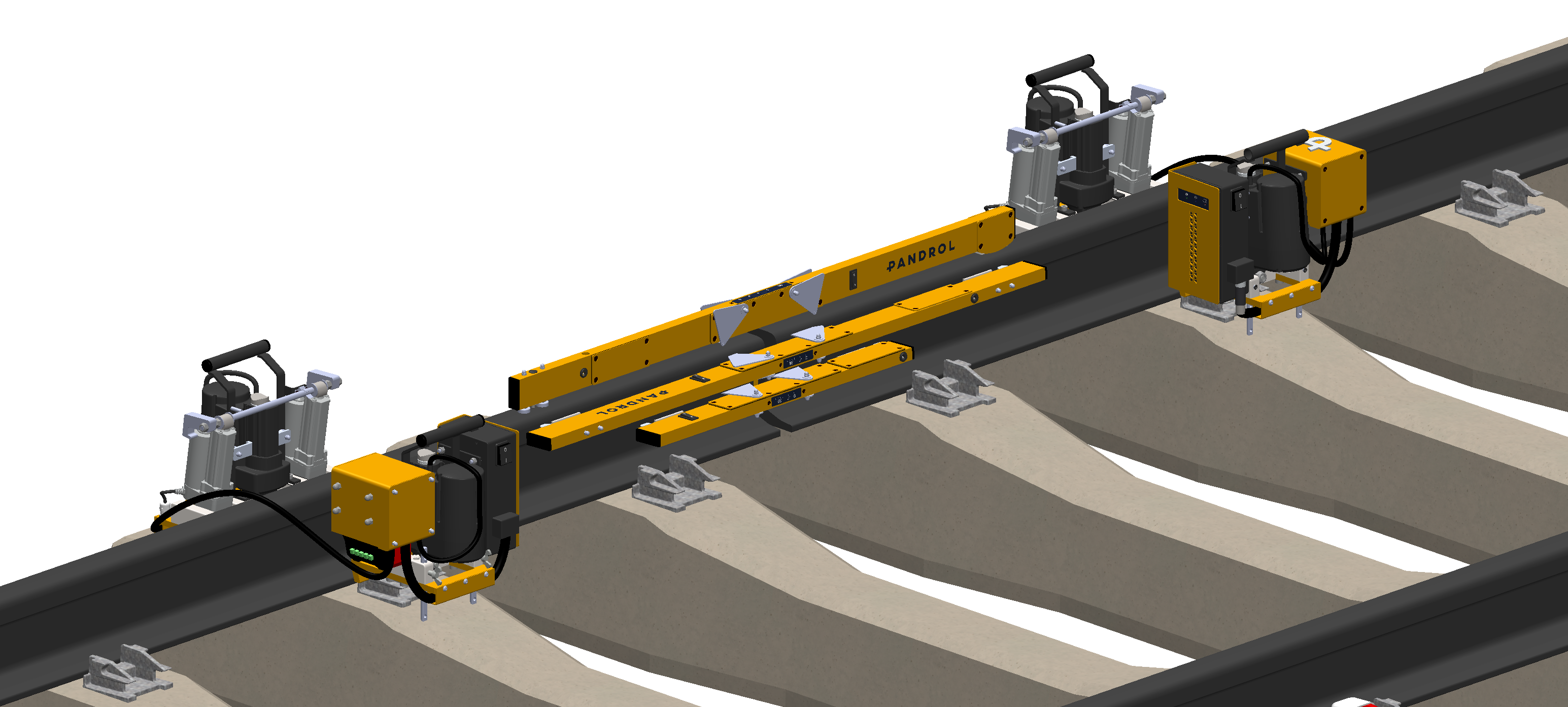

i+align product overview

Quick and easy to use, the lightweight i+align can be handled by one person.

- The operator simply sets up the device, chooses alignment parameters (for example rail type and peak), and presses start on a tablet.

- The rail is then aligned within a couple of minutes, providing exceptional accuracy for the welder and offering complete traceability.

Benefits of the i+align

Automation

By automating the rail alignment process, the i+align saves precious minutes per alignment.

Risk reduction

The risk of defective welds due to geometrical issues is reduced. Real-time data and warnings appear on the Pandrol Connect app if an alignment is not compliant.

Accuracy

Increased accuracy of rail alignment helps to reduce the risk of overpeaked welds, which makes grinding faster and significantly boosts welder productivity.

Easy to use

With i+align, rail alignment is a one-person job. The device is lightweight and easy to use, welders can be trained in a couple of days.

Safer to use

i+align is safer to use than traditional methods of rail alignment, which involve kneeling on ballast and carry a risk of finger injuries as a result of using a hammer with wedges or lifting the rail.

Increased productivity

Digital straight edges can be recalibrated locally using the Pandrol Connect app, avoiding long downtimes waiting for factory shipments.

Technical features of i+align

Alignment in three dimensions

The i+align device aligns the rail in all three dimensions: vertically (peak), laterally, and twist (cant). Accuracy is +/-0.1mm for each dimension.

Battery powered

The automatic aligner is powered by two lithium ion batteries. The digital straight edges are powered by internal batteries.

Mounted on sleeper

The device is mounted on a fastener to ensure a stable grip on the track. The basic set-up is compatible with most Fastclip and screwed fasteners, and adapters can be supplied for other fastener types.

Use on curves and worn rails

The i+align can be used on curves of up to 300m radius with the installation of counter wedges. Where rails are worn, the digital straight edges can be positioned on the external side gauge of the rail. If necessary, a manual mode can be used to adjust alignment.

Data and connectivity

The Pandrol Connect app captures all alignment data and maintenance information from the i+align and uploads it automatically to the cloud, ready for review in the office.

Ease and speed

With each basic module weighing less than 20kg, the i+align is suitable for one operator to handle and set up within two minutes. The automatic alignment is then completed within a further one to two minutes.

Products in the range

AutoSeal® moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly autoseal)

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.