The latest extension to the Florence tramway is benefiting from an innovative solution from Pandrol, which will help to reduce noise and vibration in this historic city, renowned for its impressive renaissance architecture and unique Roman heritage.

Established in the 1950s, the tram had offered both locals and visitors an effective mode of transport. However, to meet increasing demand, in 2015 Florence began a phased extension of the tramway, with stages completed in 2018 and 2025, resulting in a 7.8km extension that connects Peretola Airport to Piazza San Maro.

The Florence tramway is located just a few meters from beautiful churches, basilicas and other historical and protected buildings. With such ancient buildings in close proximity to the track, this presented a number of issues.

Firstly, there was a concern that the tramway would generate noise that could be heard in the churches nearby, disrupting worshippers and visitors to these sacred spaces. Secondly, there was a need to protect the fragile buildings from any cracks caused by ground-borne vibrations coming from the pass of trains.

In light of the above, a solution was needed to attenuate 20dBv in critical frequencies, which presented a technically demanding challenge. For that a Pandrol Floating Slab Mat solution was selected to be installed and reduce vibration levels in critical sections.

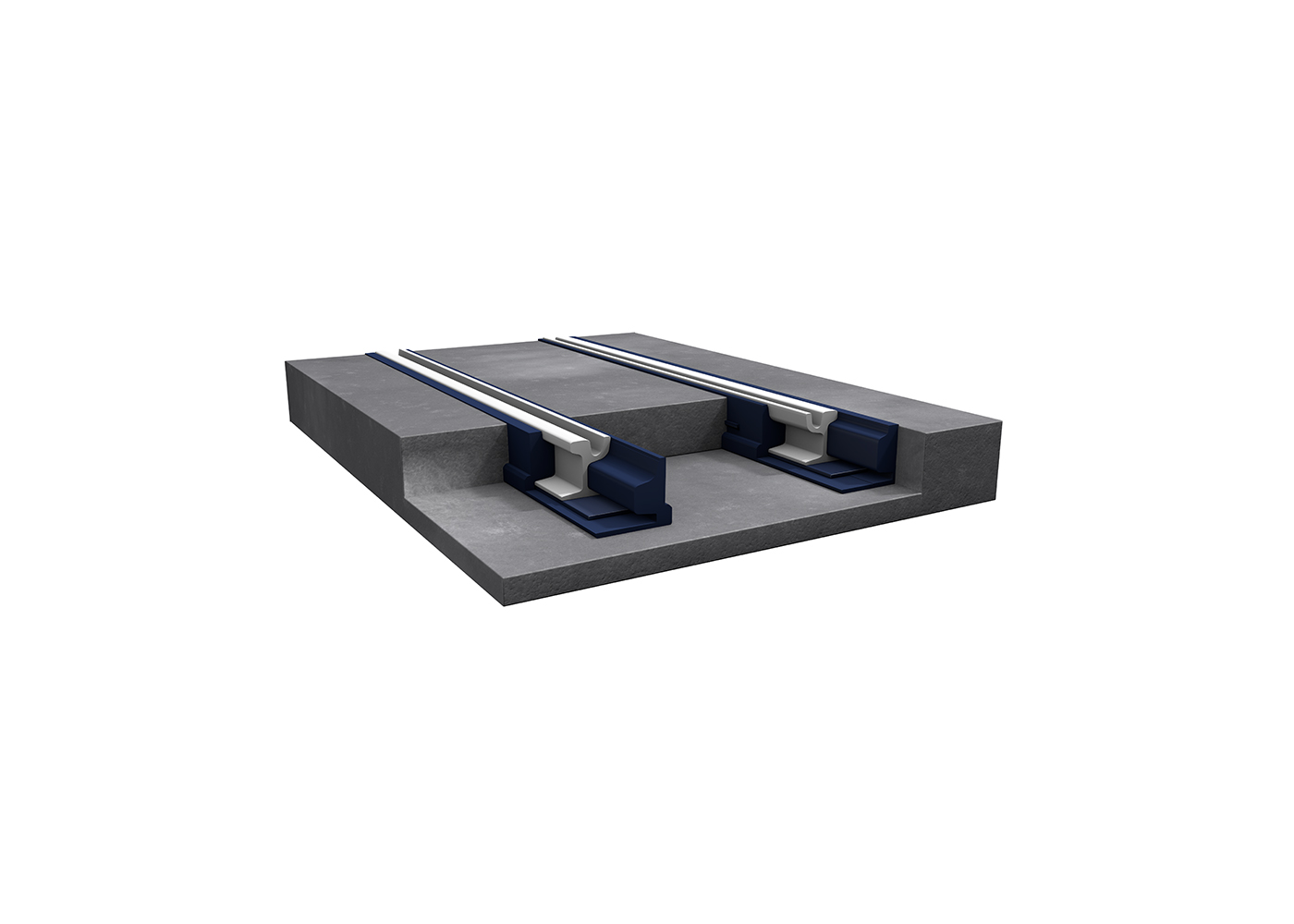

Another challenge was the presence of historical ruins below the track. As the city was first built in Roman times, beneath it lie many significant and important architectural artefacts. This dictated the excavation depths when carrying out civil works, reducing as much as possible the track structure and digging. Therefore, Pandrol QTrack® an embedded rail solution, was the best option to minimize slab thickness and civil works digging, that needs to be also integrated with urban utilities infrastructure at soil level (pipes, electricity, etc.)

Furthermore, installation needed to be quick and efficient due to the tramway’s placement in a central area so construction time needed to be kept to a minimum.

Finally, protection from stray currents was another element that needed to be considered. The tramway extension was required to protect people against electricity flow and imbalances in the electrical supply system from any leakage of currents.