QTrack® product overview

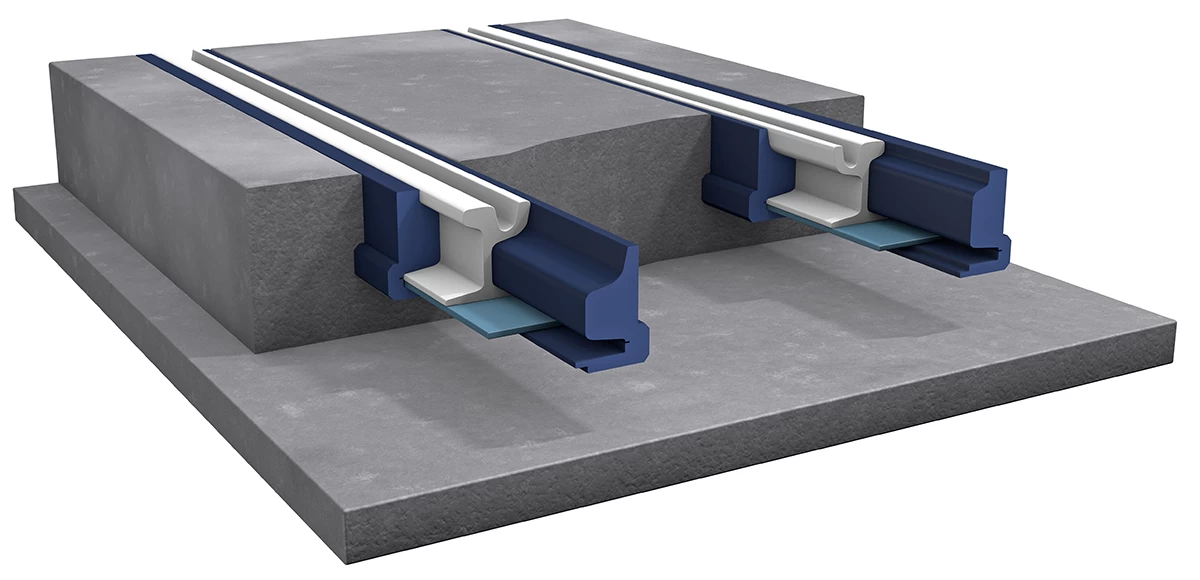

Pandrol QTrack® is an embedded, ballastless track system that provides vertical and lateral support to the rail.

It reduces vibration transmission from the rolling stock to the surrounding structures, granting control of the electrical flow out of the rails (stray currents).

- The system provides vertical and lateral support to the rail, while reducing vibration transmission from the rolling stock to the surrounding structures

- Pandrol QTrack® can be integrated and designed to match any track finishing.

- It can be installed in grooved and vignole rails for a range of applications, from tramway to heavy haul projects.

Benefits of the Pandrol QTrack®

Time saving

Pandrol QTrack® is the quickest, easiest to install embedded rail system on the market. This ease of installation saves time and manpower costs.

Multi-functional

Vibration isolation and stray current protection are provided within the same system.

Increases track quality

Even distribution of loads lowers vibration emissions and increases the track quality.

Increases track longevity

The homogeneous stiffness of the track controls rail corrugation and results in less grinding activity. This reduces maintenance and increases track longevity. Pandrol QTrack® has one of the lowest lifecycle costs of systems on the market.

Versatile

The ability to adjust stiffness levels to achieve specific attenuation levels makes Pandrol QTrack® a flexible, versatile option.

Technical features of Pandrol QTrack®

Noise & vibration attenuation

Pandrol QTrack® can be tuned to attain different stiffness levels in order to meet the required vibration limits.

Electrical insulation / stray current: QT ELEC

To protect against the effect of stray currents, an optional, ad-hoc electrical insulation film is possible, known as QT ELEC. QT ELEC is available in three different levels of isolation: ELEC-L, ELEC-H and ELEC-M.

Designed for quick installation

Pandrol QTrack® utilises a top-down installation method and can be installed at a rate of up to 144 linear meters of single track per team and per day.

Encapsulation of switches and crossings

The system is fully developed to provide full encapsulation of switches and crossings. Tailor-made pieces along with a customised layout drawing are delivered for encapsulation of the turnouts on site.

Integration in Prefab panels

QTrack® system can also be designed and integrated in pre-fabricated concrete beams or slabs for a quick installation in projects that require a minimum traffic disruption.

Sustainability & very low carbon footprint

Rubber QT encapsulations are made of more than 90% of recycled materials and are 100% recyclable, contributing to the circular economy and help improving environmental conditions.

Related products

In the Pandrol FTrack system, the rail is fastened by discretely supporting rail fixations and embedded by FT ENCAPSULATION – resilient rail-web filler profiles.

FTrack

Pandrol Under Ballast Mats (UBMs) can reduce life cycle cost of the railway and/or vibration attenuation for ballasted track. Easy to install, maintenance free and compatible with all types of track design, they aim to reduce the lifecycle costs of the railway.

Under-Ballast Mats

The Pandrol Floating Slab Mat (FSM) is a high-performing vibration attenuation floating slab system. Easy to install, maintenance free and compatible with all types of rail and track systems, it has been designed to reduce the lifecycle costs of the railway.

Floating Slab Mat

Pandrol Under Sleeper Pad (USP) solutions reduce maintenance requirements, increase track quality and provide vibration attenuation to Ballasted Track.