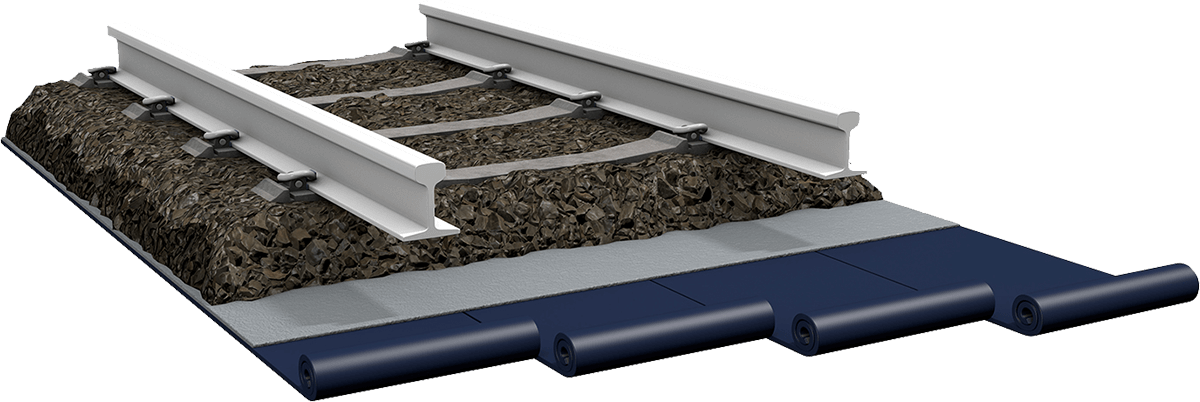

Under-Ballast Mats

Pandrol Under Ballast Mats (UBMs) can reduce life cycle cost of the railway and/or vibration attenuation for ballasted track. Easy to install, maintenance free and compatible with all types of track design, they aim to reduce the lifecycle costs of the railway.

Under-Ballast Mat Product overview

UBMs operate on the mass-spring principle. The ballasted track (the mass) is elastically supported by a continuous resilient mat (the spring). The elastic properties of the mat solution are defined by track and train design, mat material, system thickness, number of resilient layers and determined shape factor.

- Pandrol UBMs are made from high-quality resin-bonded rubbers.

- The design parameters can be adjusted to achieve a vibration attenuation up to 25 dBv.

Advantages of using Pandrol UBM

Simple to install

Rapid, simple installation saves time and labour costs.

Maintenance free

Hardwearing and maintenance free, Pandrol UBM Solutions maintain cost-effectiveness throughout the lifecyle.

Compatibility

Compatibility with all types of ballasted track systems means that Pandrol UBM Solutions have a wide range of applications.

Wide product range

Pandrol UBM Solutions are available in a wide range of stiffnesses and provide flexible vibration isolation that can be modified to meet particular requirements.

Sustainability

Pandrol UBM Solutions have a low environmental impact and increase the sustainability of the track.

Technical features of the Pandrol UBM

Designed for fast and simple installation

Under Ballast Mats are supplied in rolls. These are easy to install in single or double layers, plus the addition of a bottom stabilisation layer if required. The systems do not have closing joints between these layers, further simplifying installation.

Extended lifespan

Designed to last, Pandrol UBMs have tested and proven long-term stable properties and continued performance. They are highly resistant to changing atmospheric conditions, chemical exposure and mechanical fatigue.

Water permeability

Pandrol UBM solutions UBMs are fully water permeable in both the vertical and horizontal planes, meaning that drainage characteristics of the track are unaffected when the mats are installed.

Vibration isolation

Available in a wide range of stiffnesses, Pandrol UBMs provide a tuneable approach to vibration isolation that can be modified to meet exact requirements. A resonance frequency as low as 14 Hz can be achieved.

Geotextile protection layer

A non-woven geotextile protection layer is used to protect mats against ballast stone penetration. In addition, the geotextile protects joints between the mats and acts as a filter for small particulates while retaining water permeability.

Sustainability

Pandrol Under Ballast Mat Solutions are made from 90% recycled materials and are 100% recyclable.

Related products

In the Pandrol FTrack system, the rail is fastened by discretely supporting rail fixations and embedded by FT ENCAPSULATION – resilient rail-web filler profiles.

FTrack

The system, when installed in concrete, provides support to all sides of the rail and allows stringent vertical and lateral support criteria to be met, and at the same time offers vibratory and electrical decoupling from its surroundings.

QTrack®

The Pandrol Floating Slab Mat (FSM) is a high-performing vibration attenuation floating slab system. Easy to install, maintenance free and compatible with all types of rail and track systems, it has been designed to reduce the lifecycle costs of the railway.

Floating Slab Mat

Pandrol Under Sleeper Pad (USP) solutions reduce maintenance requirements, increase track quality and provide vibration attenuation to Ballasted Track.