FTrack

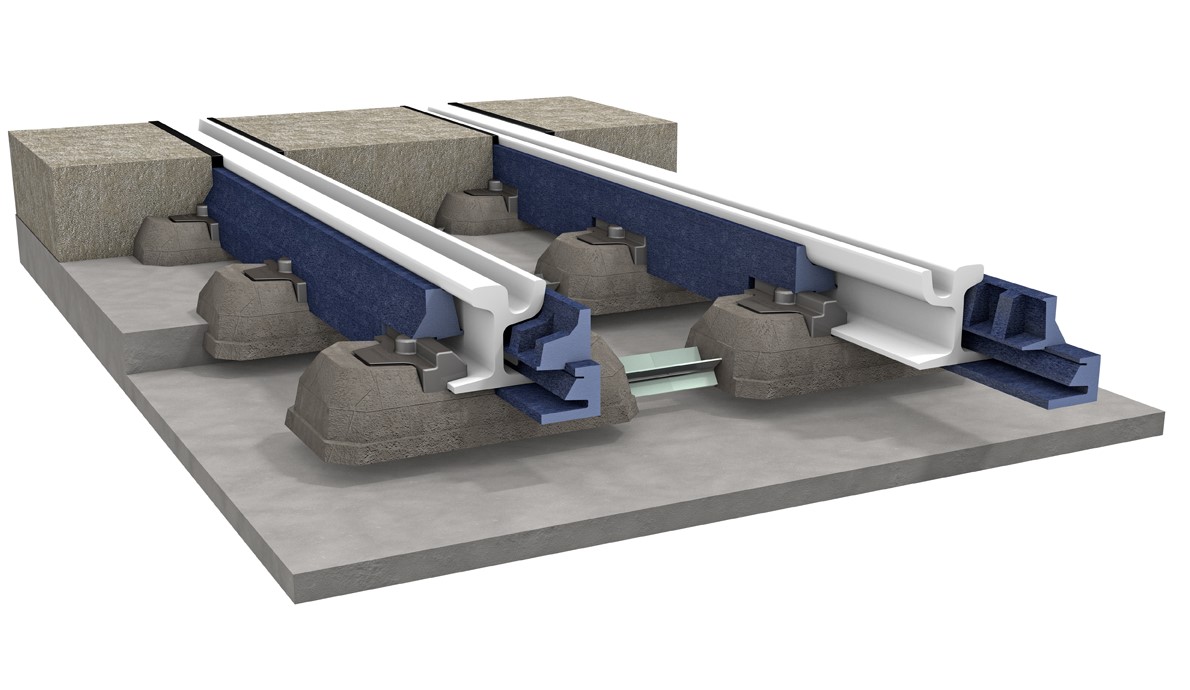

Decouple the rail from its whole environment with Pandrol FTrack, which provides Flexiweb rubber profiles for discrete or continuously supported track. The Pandrol FTrack Fastening System uses embedded FT Encapsulation and discretely supporting rail fixations to fasten the rail securely. This maintenance-free system does not interfere with any other typical embedded track maintenance activity.

Pandrol FTrack Explained

Most light rail systems in urban settings run along rails embedded in the slab structure beneath. With the Pandrol FTrack systems rubber encapsulations, the correct decoupling of the rail from the surrounding concrete and/or track finishing structure is enhanced, ensuring smoother running.

The FTrack’s encapsulations are designed to improve the dissociation of the rail and its immediate environment, the transfer of loads from one medium to the other, and the quality of the road-finishing layer – be it concrete, natural grass, clinkers, or asphalt.

One of FTrack’s most beneficial added values is that it combines the best technical performance with an extremely low carbon footprint, certified by an Environmental Product Declaration (EPD).

- A maintenance-free system

- Extremely low-carbon footprint fastening solution

- Suitable for resilient rail-web filler profiles

Downloads

Advantages of using Pandrol FTrack

Maintenance-free

Save time and cost with a maintenance-free solution. While requiring no maintenance itself, FTrack is compatible with other standard rail maintenance operations such as grinding and gauge corner restoration, meaning less disruption to the system.

Low carbon footprint

Create a more sustainable track infrastructure with a fully recyclable solution made from more than 90% recycled materials. As it has the lowest CO2 footprint of all products on the market (as certified by EPD), FTrack helps rail operators improve their circular economy.

Value for money

As a maintenance-free solution, FTrack provides excellent value for money due to its long lifespan and low initial product and installation costs.

Easy installation

Install FT encapsulation without any additional components or adhesives, cutting down both the time and cost associated with FTrack installation.

Versatility

Adapt the FTrack solution to the spacing a geometry of any type of sleeper and fastening configuration for maximum versatility.

Adaptability and compatibility

Ensure the best possible track design for each application of FTrack, keeping stray currents under control. When combined with the NABLA Tram Fastening system, FTrack provides a cutting-edge, fully embedded track solution for urban environments.

Technical features of the Pandrol FTrack

Bespoke encapsulation

FT encapsulation can be uniquely engineered for the fastening system it is being applied to, in order to accommodate grooved and vignole rails, protection cover, and support spacing between sleepers. Variations are also compatible with all road finishing layers – including concrete, grass, asphalt and concrete – regardless of the choice of top-sealing joint.

Noise and vibration attenuation

Precisely tune FTrack encapsulations to the shape and stiffness characteristics of your track and environment for enhanced performance on every rail system.

Easy-to-fit profiles

Fir the rubber profiles onto the rail with ease. No special components or adhesives are required to install them, making FTrack and fast and convenient solution.

High-density rubber

Rely on FTrack’s quality construction. The rubber used is high-density and strong, providing long-lasting performance that withstands vertical and shear forces without the need for extra top-sealing joints.

Related products

Pandrol Under Ballast Mats (UBMs) can reduce life cycle cost of the railway and/or vibration attenuation for ballasted track. Easy to install, maintenance free and compatible with all types of track design, they aim to reduce the lifecycle costs of the railway.

Under-Ballast Mats

The system, when installed in concrete, provides support to all sides of the rail and allows stringent vertical and lateral support criteria to be met, and at the same time offers vibratory and electrical decoupling from its surroundings.

QTrack®

The Pandrol Floating Slab Mat (FSM) is a high-performing vibration attenuation floating slab system. Easy to install, maintenance free and compatible with all types of rail and track systems, it has been designed to reduce the lifecycle costs of the railway.

Floating Slab Mat

Pandrol Under Sleeper Pad (USP) solutions reduce maintenance requirements, increase track quality and provide vibration attenuation to Ballasted Track.