i+cool product overview

The equipment can be used for normal gap, wide gap and head wash repair (HWR) welding.

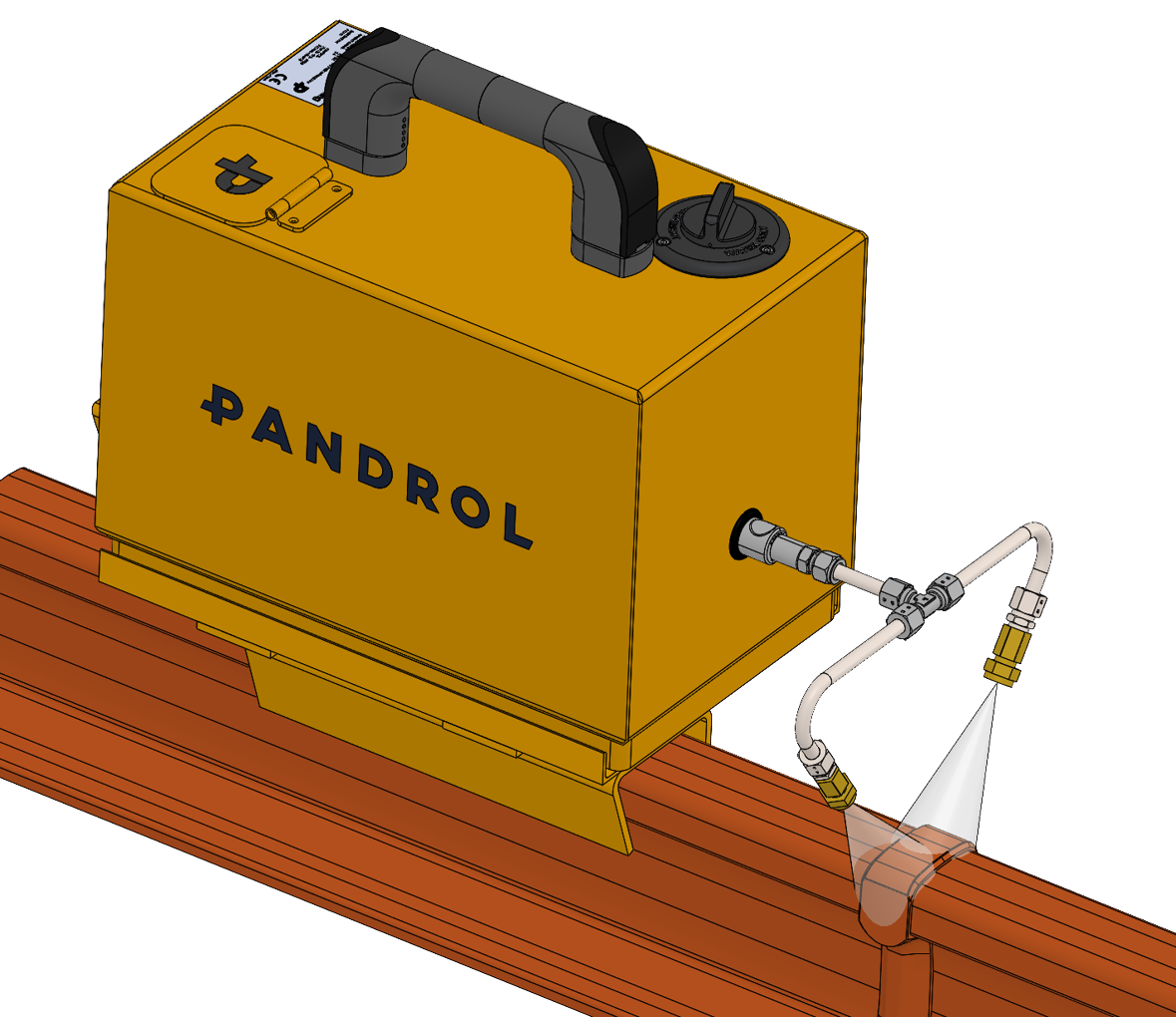

- The compact device- which weighs just 20kg when ready for use- is equipped with an integrated water tank

- A mist of water is sprayed from nozzles to cool the weld to the optimum temperature for grinding

- As a result, the overall time needed to complete the weld is reduced, while the quality and integrity of the weld are maintained

Benefits of i+cool

Faster Welds

By cooling welds faster, i+cool increases welding productivity, saving time and money for the rail operator.

Maintained

Integrity of the weld maintained (no martensite or bainite).

Money saving

Weighing just 20kg (including batteries and water), the device can be carried by a single person, saving on operator time and costs.

Easily operated

The i+cool device is simple to use, thanks to its ease of set-up, automatic timer and controlled stop.

Versatile

Compatible with Pandrol’s i+heat support and suitable for normal gap, wide gap and HWR welding, the system minimises the amount of equipment needed on track.

Technical features of i+cool

Ease of set-up

The device’s nozzles – made of stainless steel plug easily into the integrated water tank.

Process control

The i+cool device is fitted with an automatic timer and a controlled stop.

Battery powered

The system is powered by 18V (8Ah) battery.

Compact and lightweight

With a maximum weight of just 20kg and fitted with a sturdy handle, the equipment can be carried on site by one person.

Support

The device is compatible with the support for Pandrol’s i+heat preheater system, reducing the amount of equipment needed on site.

Versatility

The versatility of i+cool’s design means that one device can be used with normal gap, wide gap and HWR welding.

Related products

i+seal moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly AutoSeal®)

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

The revolutionary i+align automatic aligner has been designed to transform rail welding through precise, automated rail alignment.