Third Rail Systems product overview

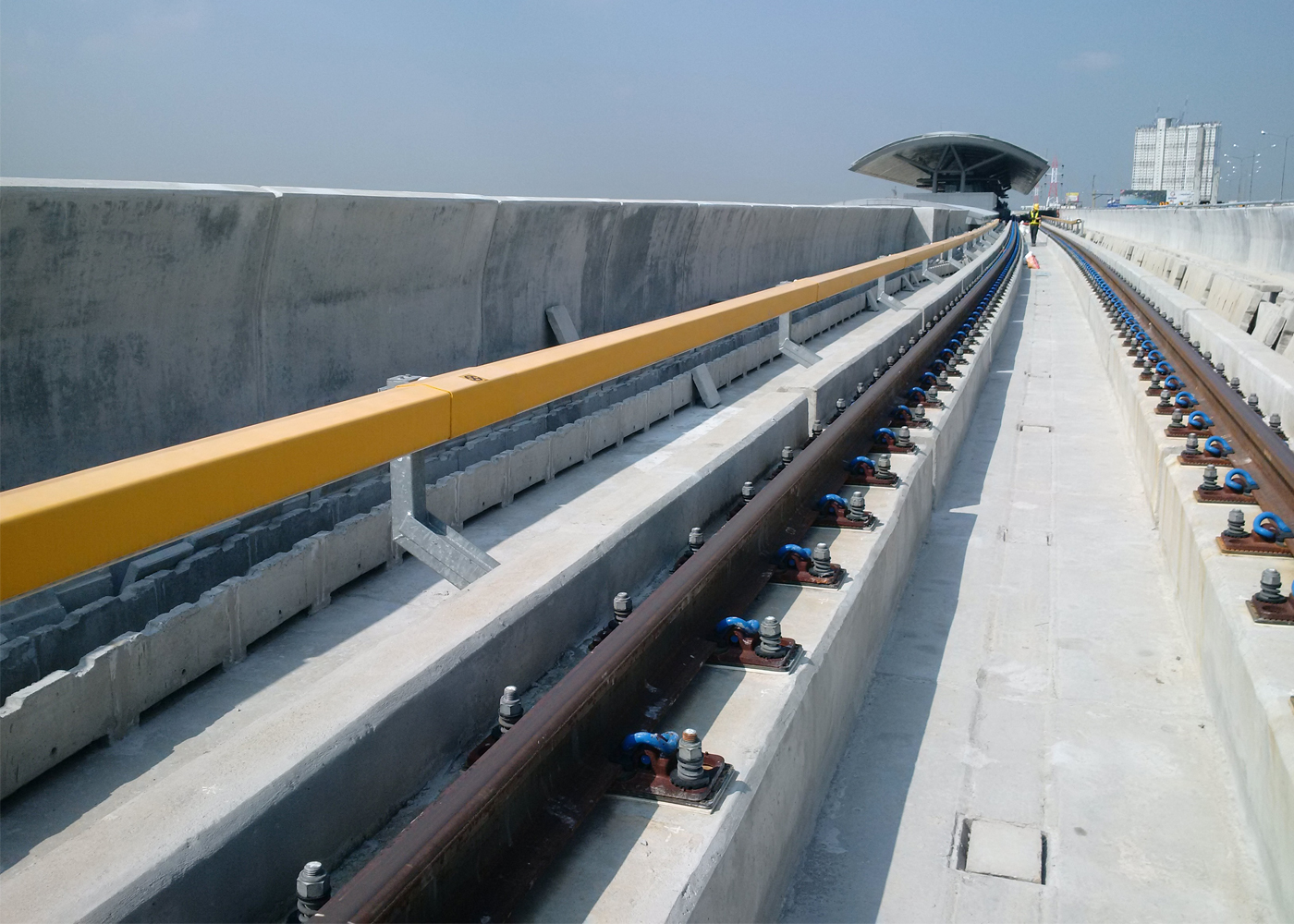

RAS technology sees the aluminium and stainless steel conductor rail made with coextrusion process, creating a long lasting and reliable material that’s a game-changer in the development and manufacture of complete composite conductor rail systems solutions.

- This revolutionary method delivers the highest levels of reliability and safety on the market, with no delamination (separation of the combined metals) and – because it works down to 0 mm – no need to monitor the thickness of the stainless steel.

- Pandrol’s third rail solutions are specifically designed with consideration of rolling stock, track works, power supply and civil works interfaces in mind, which means they can be adapted to work on all track types.

- The Pandrol team has extensive across-the-board experience and offers a comprehensive RAS support service, from product engineering and design, through to proof of concept testing, system design, installation supervision and bespoke training.

Downloads

Advantages of using our Third Rail Systems

Leading the world

Working with Pandrol means working with world leaders in third rail technology.

Cost-effective design

‘Railtech Alu-Singen (RAS)’ system is quick, cost-effective and simple to install and maintain – as well as offering the best lifespan on the market.

Reduced maintenance

The system is configured so that the stainless-steel strip can be fully worn down to 0 mm without any need to check that it’s still working, generating significant cost reductions on maintenance.

Maximum flexibility

The system is capable of offering top, lateral and under-running solutions.

Enhanced lifetime value

All Pandrol products have been specifically designed with the wider railway environment in mind. Every product and process is tested to meet the highest standards of safety, reliability and lifetime value.

Technical features our Third Rail Systems

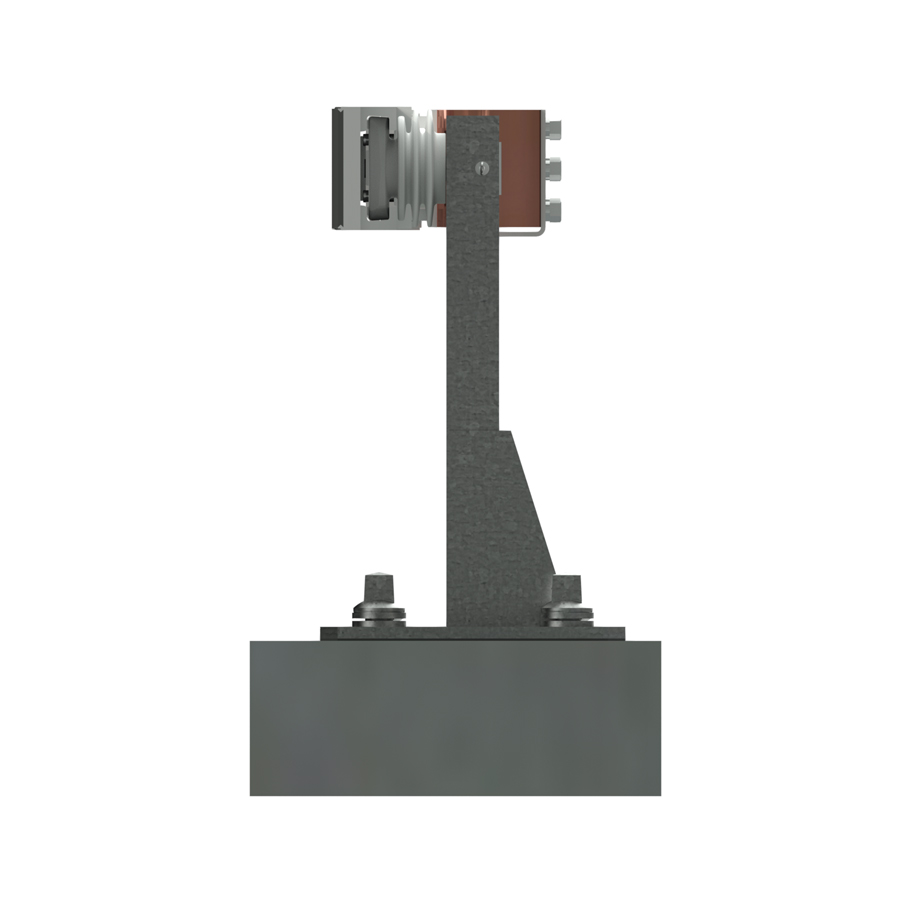

Coextrusion technology

Coextruded rail delivers industry-leading levels of reliability and safety, with an increased lifetime. The highly specialised coextrusion process which ensures there’s a strong, reliable, corrosion-free bond between the aluminium body and the stainless steel strip. The risk of delamination of the stainless steel strip – even if it has been partially worn down – is completely eliminated when the RAS system is used.

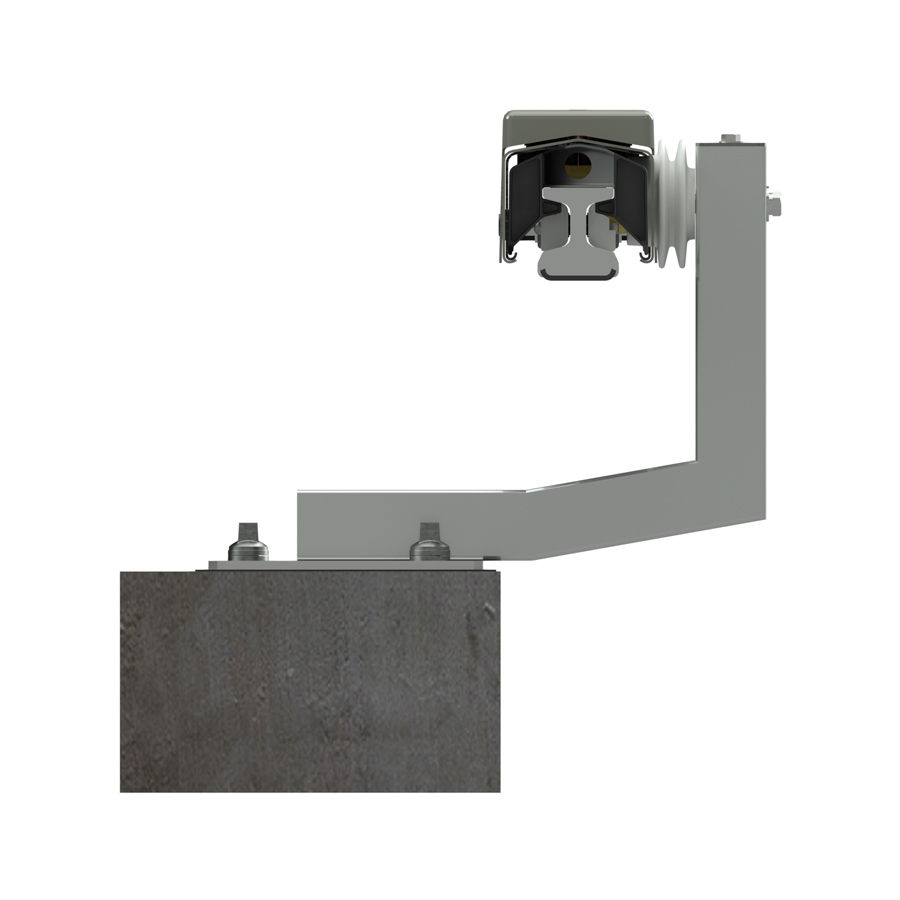

Insulation protection

Our insulating covers provide the highest possible levels of safety and protection for people working near the track.

Global track expert

We propose integrated track solutions with our Division Fastening Systems. With our track expertise, we are able to anticipate and solve issues proposing the best solution for the product and its interface with its environment.

Specialised tooling

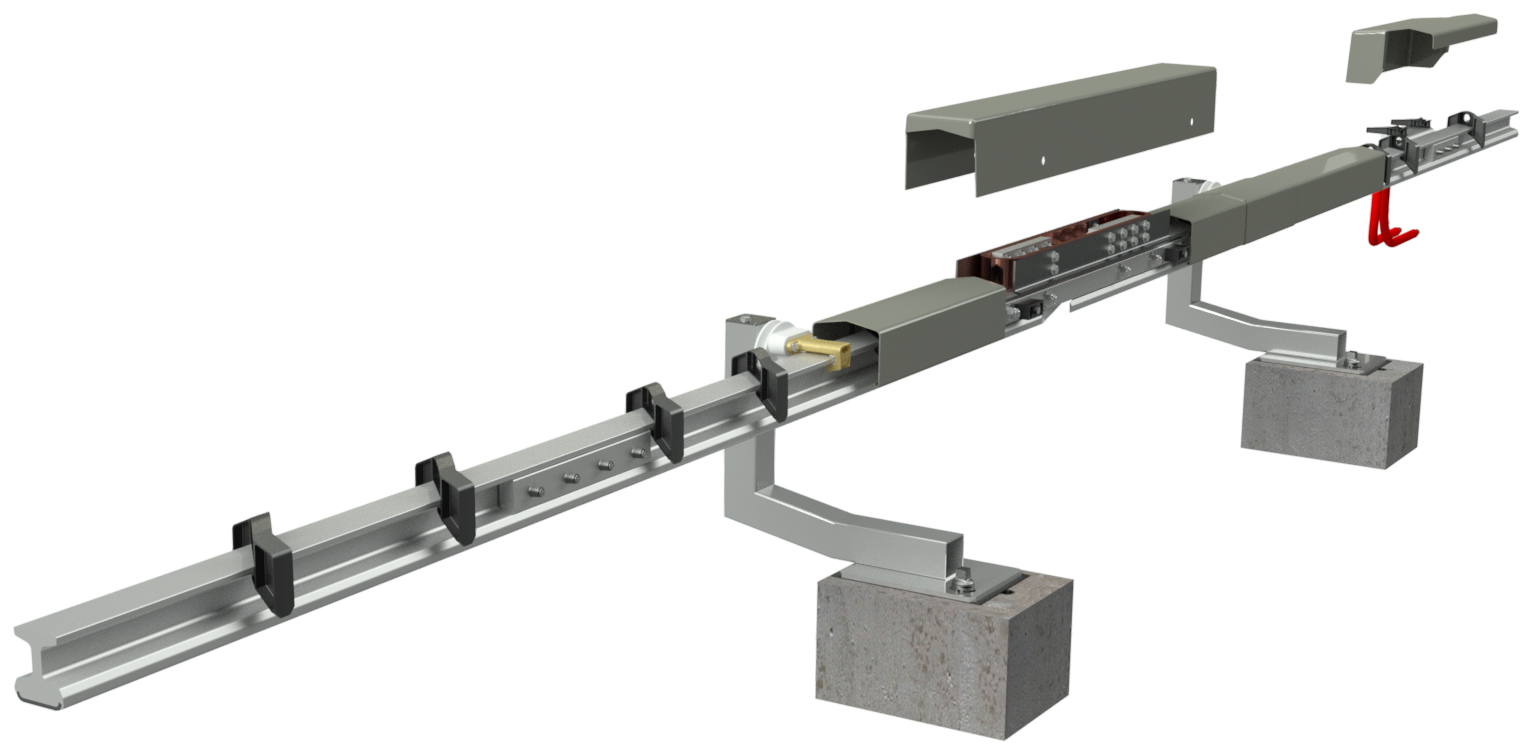

We have developed a full range of dedicated tools to ensure the third rail installation is as smooth and as cost-effective as possible. Added to this, all of our processes and materials are underpinned by the philosophy that all installation and maintenance activities need to be fast, reliable and safe.

Unmatched engineering and field expertise

With over 2000 km of our third rail installed across the globe, we’re truly world leaders in the field. Our expert teams have the knowledge, reactivity and flexibility to support you at every stage of your journey – and our unrivalled field experience means we’re always prepared for whatever surprises are thrown up along the way.

Solutions

Components

-

![Conductor Rail]()

Conductor Rail

Coextruded rail combining aluminium & stainless steel

-

![Splice Joints]()

Splice Joints

A pair of aluminium extruded splices (plates) fixed to the web of the conductor rail using a bolting connection

-

![Ramps]()

Ramps

Used to evenly engage and disengage the train current collector shoe during transitions

-

![Insulators & Brackets]()

Insulators & Brackets

Manufactured in a glass reinforced polyester, designed to insulate the third rail system and withstand mechanical stresses

-

![Mid Point Anchors]()

Mid Point Anchors

Designed to control the expansions and contractions of the third rail system, caused by temperature variation

-

![Expansion Joints]()

Expansion Joints

Designed to accommodate thermal expansion and contraction of the third rail system, due to ambient temperature variation and heat rise

-

![Cable Terminals]()

Cable Terminals

Fixed to the web of the conductor rail by means a bolting connection

-

![Insulated Joints]()

Insulated Joints

Designed to split (insulate) two electrical sections of third rail system

-

![Covers]()

Covers

Fastened to the conductor rail to minimise the risk of electrical shock due to accidental contact with the conductor rail and to provide protection against debris

Related products

Designed for any rolling stock equipped with pantograph, our safe system interlocks with a range of existing maintenance depot equipment, including disconnectors, walkways, bridge-cranes, doors, signalling equipment and lifting platforms.

Retractable Catenary

More than 2,000km are installed in rail networks around the world, particularly in tunnels, with a specific retractable version for application in depots.