We provided our SRS and DRS fastening solutions for elevated sections of the Red Line, with Pandrol e-Clip used for ballasted sections. Like all of our fastening systems, these are an evolution of time-tested technologies, renowned for their safety and reliability. The SRS and DRS fastenings bring particular benefits in terms of insulation and noise and vibration mitigation, making them ideal for use in the city-centre setting. On ballasted track, our under-sleeper pads were used to reduce vibration levels in sensitive areas.

Our PLA one-shot crucible aluminothermic welding kits were used to weld the Red Line’s long rail strings together, including for wide-gap welding. The solution provided is of the highest quality in South East Asia. The welding team from Worksop team assisted with training in the use of the technology, including instruction and demonstration of products and equipment, and welder certification.

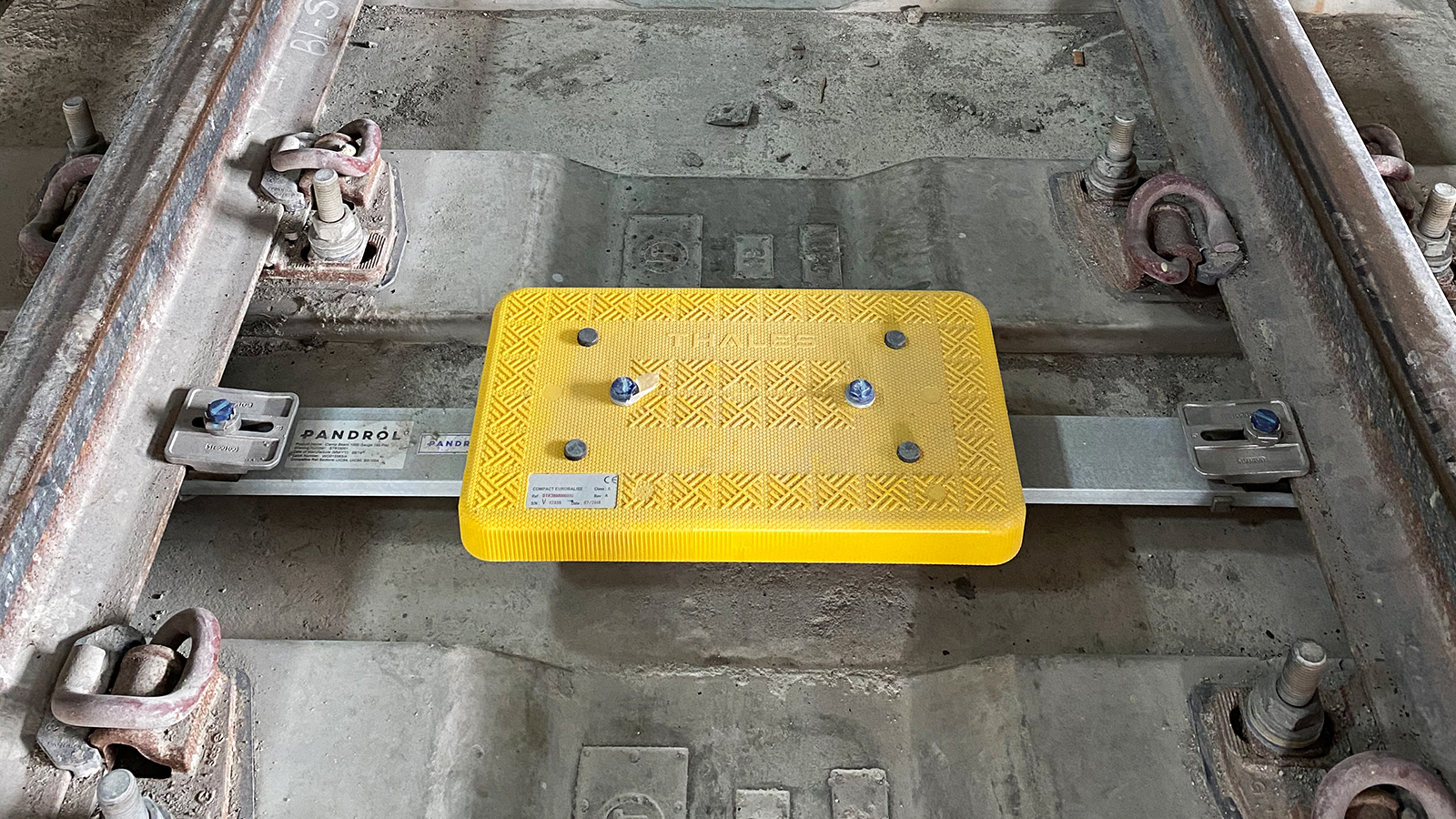

To support the Red Line’s European Train Control System (ETCS) signalling, we supplied Vortok clamp beams. This non-intrusive balise transponder mounting system uses the rail fastenings to hold the beam in track, eliminating the need to drill sleepers or dig out ballast. As a result, installation typically takes less than five minutes per balise. Once installed, the beam is completely insulated, vibration resistant, strong and durable, ensuring a long life on the Red Line.

For the Red Line depot, we supplied and designed the retractable rigid catenary system for the electrification. Adapted, reliable and secure, this will allow work to take place in safety and ease maintenance operations on trains. In addition, the Pandrol FR fastening system was used in the depot – an elastic fastening that brings benefits in terms of vibration attenuation, creep resistance and electrical insulation. The assembly is designed for long life, can be fully dismantled for inspection and maintenance, and all parts are replaceable.