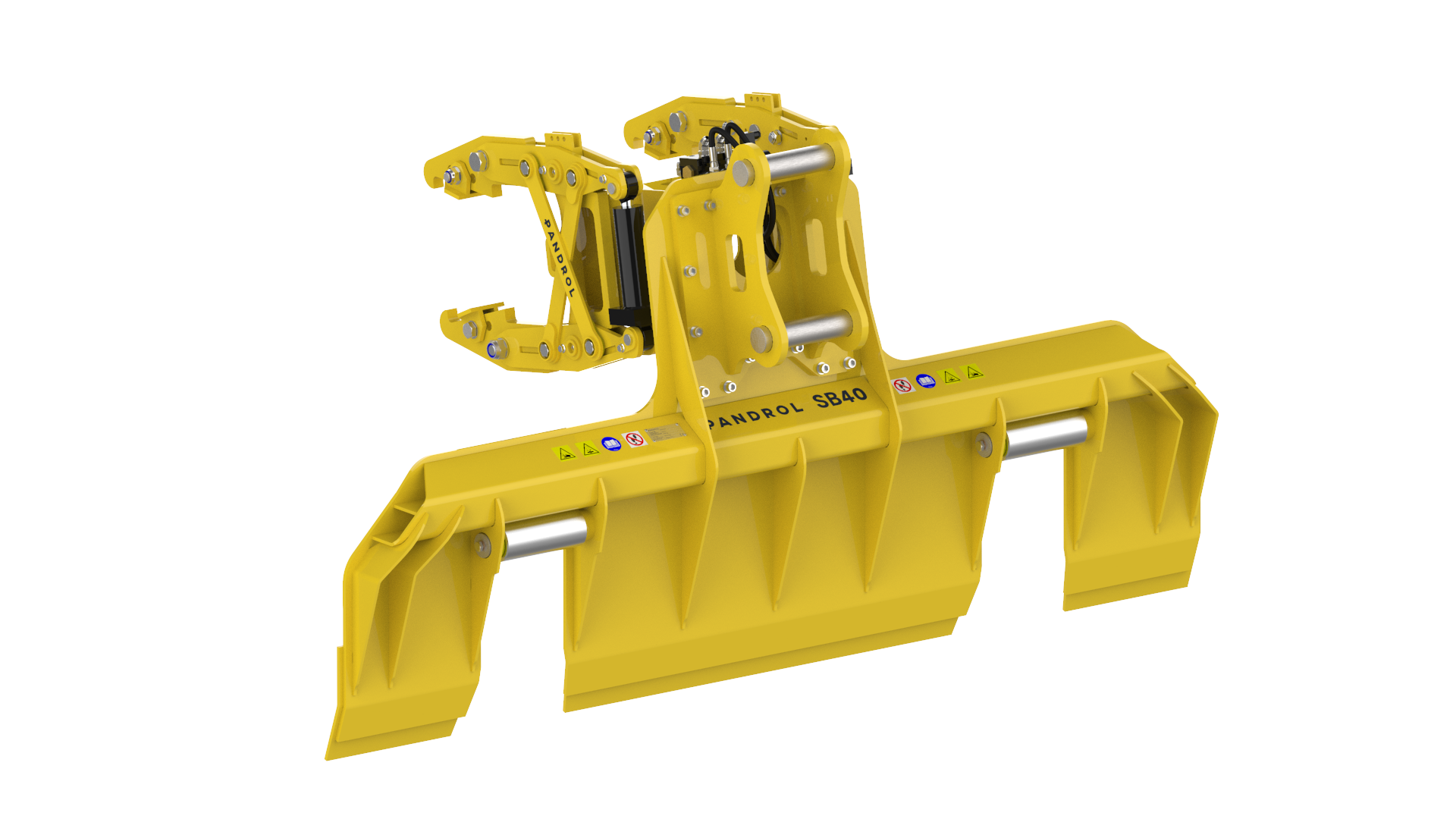

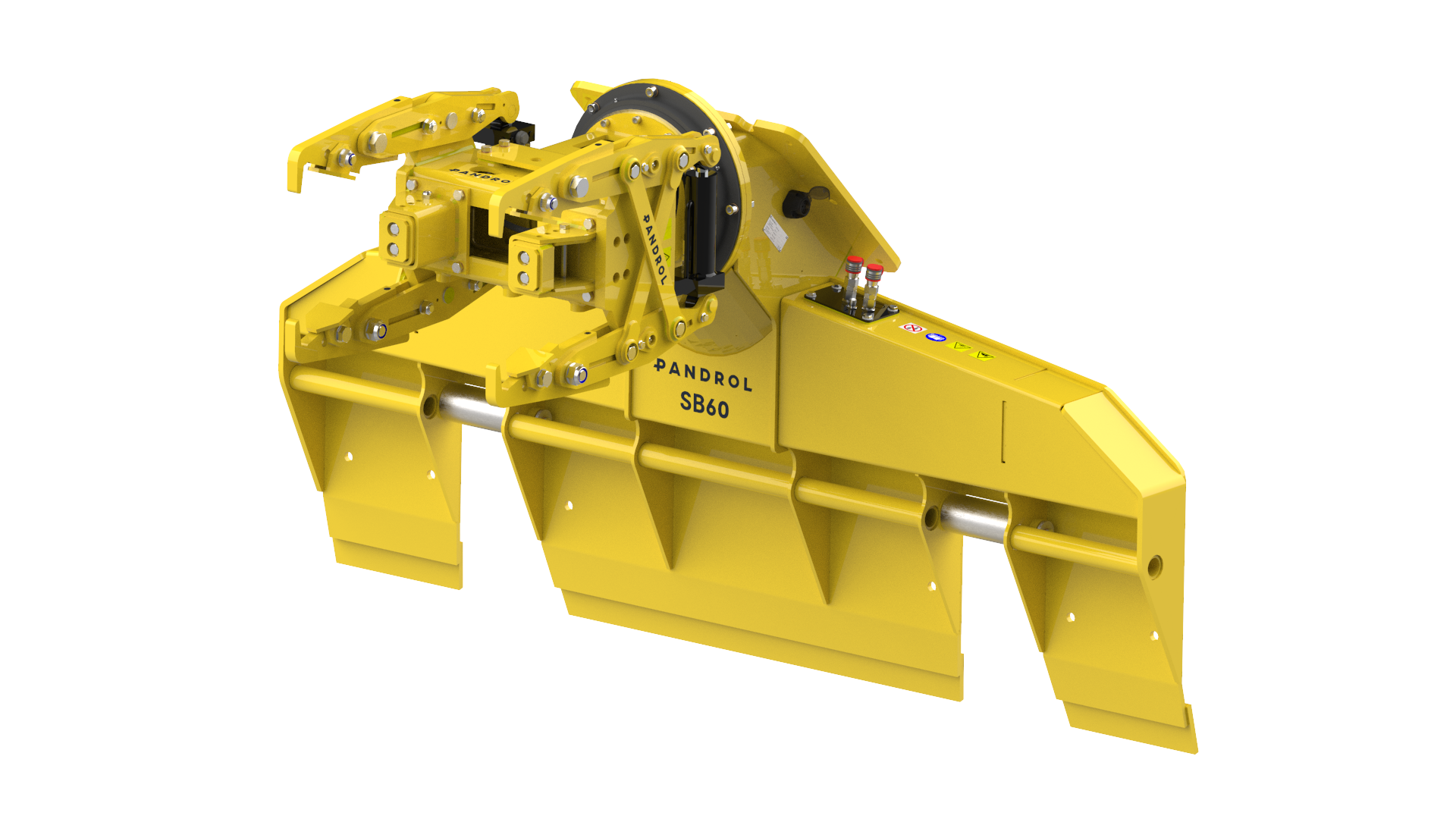

Sleeper Replacer SB40 / SB60

Pandrol’s SB40 and SB60 Sleeper Replacers are attachments designed to replace sleepers safely and efficiently.

Sleeper Replacer SB40/SB60 product overview

Pandrol’s SB40 and SB60 Sleeper Replacers are high-performance excavator attachments designed to make track work faster and safer.

- The SB60 has innovative tilt and rotate functions that allow sleepers to be changed from both the middle and the side of the track.

- The SB40 provides the same cost-effective, safe solution, but has been designed specifically for smaller carrier machines (weighing 8 to 12 tons) that are equipped with a permanently fitted tilt rotator. It is approximately half the weight of the SB60.

- Both attachments can be combined with Pandrol’s Auto Master clipping attachment for swift, safe installation of Pandrol’s FC and FE Fastclips on new sleepers.

Downloads

Advantages of using the Sleeper Replacer SB40 / SB60

High performance

Pandrol’s Sleeper Replacers are high-performance machines that increase productivity and save time.

Cost-effective design

Because the Sleeper Replacers can dig out, remove and replace the sleeper with one attachment, they offer a simple, cost-effective option.

Enhanced track safety

Fewer people are needed on track to carry out sleeper replacement, improving safety.

Auto Master Clipping

When fitted with an Auto Master clipping attachment, the Sleeper Replacers can also be used for fast, efficient installation of Pandrol’s FC and FE Fastclips.

Maximum flexibility

The SB60’s innovative tilt and rotate functions create maximum flexibility, allowing sleepers to be changed from both the middle and side of the track.

Operate in small spaces

Because the blade remains stationary and only the grapple rotates, the SB60 is suitable for use in limited spaces such as station platforms and tunnels.

Technical features of the Sleeper Replacer SB40 / SB60

One versatile attachment

The SB40 and SB60 Sleeper Replacers dig out, remove and replace sleepers using a single attachment.

High compatibility

The Sleeper Replacers are compatible with most types of sleepers and are available in various track gauges.

Tilt and rotation

The SB60 Sleeper Replacer can be tilted and rotated, allowing sleepers to be changed from both the middle and side of the track.

Compact design

The Sleeper Replacers are compact in design and the SB40 is particularly lightweight.

Accessories

Several accessories are available including the Auto Master for automatic clipping, a bucket attachment for removing ballast, and a bucket attachment for wet spots.

SB40 (for smaller carrier machines)

SB60 (for larger carrier machines)

Specifications

Auto Master Clipping Attachment for SB40 and SB60

Clip new sleepers onto the rail with just one press of a button. The Auto Master Clipping Attachment minimises the number of people needed for clipping during re-sleeper operations.

Developed as an accessory for the Sleeper Replacer SB40 and SB60, the Auto Master enables Pandrol Fastclip FC and FE to be fitted automatically, increasing site safety by reducing the amount of staff on track.

This self-centering machine can handle a variety of rails and sleepers and is supplied with CE certification as standard.

Technical Features:

- Installs Fastclip FC and FE

- Installs Safelok I and III

- Operated from the cab of the carrier machine

Advantages:

- Increases site safety by reducing the amount of staff on track

- Minimises the number of people needed for clipping during re-sleeper operations

- Vastly improves the production rate

Specifications

Related products

Pandrol rail clamps offer a reliable solution for the installation and maintenance of long welded rails, compatible with all types of transport and laying equipment.

Rail Grabber RG2500-RG3000-RG4800

A telescopic frame makes the Sleeper Layers compact and safe to operate. A unique, patented linkage system ensures that the centre of gravity does not change during sleeper spreading.

Sleeper Layer Attachments SL400/SL450/SL550/SL650/SL850

The Auto Master enables clipping to take place automatically, as part of a seamless process. With six to eight fewer people required on track to perform the operation, the machine has a major impact on site safety.

Automaster (For Sleeper Replacers SB40/SB60)

Capable of handling both sleepers and rail, the Sleeper Grabber improves installation efficiency and sleeper reuse.

Sleeper Grabber SG60

Pandrol’s rail tongs are used to install and maintain continuous welded rail (CWR). The rail tongs clip automatically onto the rail being moved and are designed to be fastened to all types of hauling and rail removal equipment.

Rail Tongs

Pandrol have designed three types of track jacks: hydraulic, mechanical and obstructionless. They have all been designed for easy use, maximum operator safety and to be high performing in all working conditions.

Track Jacks

Once lifted, the rail can be moved with very low friction for the purposes of rail stressing. The resultant stress distribution is, therefore, optimised.