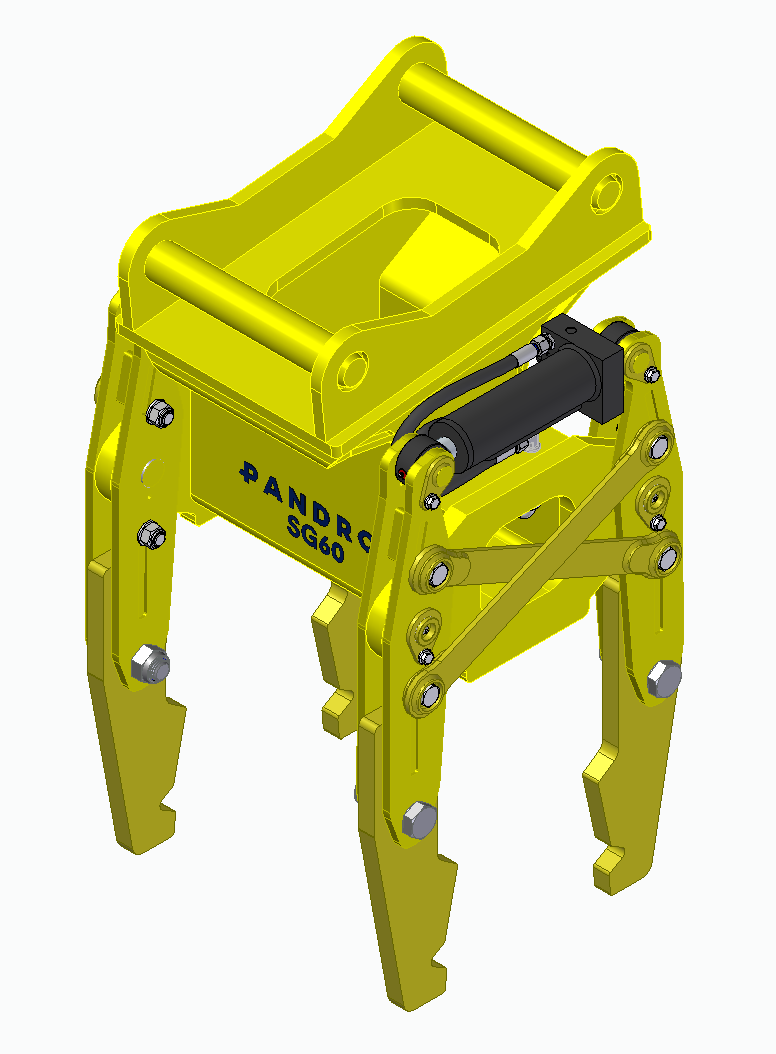

Sleeper Grabber SG60

Capable of handling both sleepers and rail, the Sleeper Grabber improves installation efficiency and sleeper reuse.

Sleeper Grabber SG60 product overview

The SB60 Sleeper Grabber has been specifically developed to handle sleepers and rail sections efficiently. By avoiding damage to sleepers, it facilitates their reuse.

The Sleeper Grabber’s design is based on Pandrol’s Sleeper Replacer SB60, which has a time-tested track record for reliability.

- The Sleeper Grabber SG60 enables fast and seamless lifting of both sleepers and rail sections, enhancing productivity and reducing maintenance time.

- Its secure grip prevents sleeper damage, enabling reuse and minimizing waste, while its design prioritizes worker safety by eliminating the need for hands near the grip.

Downloads

Advantages of using the Sleeper Grabber SG60

Streamline sleeper handling

The Sleeper Grabber SG60 streamlines the complex sleeper handling procedure, lifting both sleepers and rail sections.

Prevent sleeper damage

Secure and gentle handling of sleepers means more can be reused during maintenance, reducing wast.

Enhanced safety

Track workers’ safety is increased as they do not need to put their hands near the sleepers/grip when using the Sleeper Grabber SG60.

Time-tested technology

Based on Pandrol’s time-tested Sleeper Replacer SB60, the Sleeper Grabber is a reliable, cost-effective option.

Technical features of the Sleeper Grabber SG60

Fast operation

The Sleeper Grabber SG60 can handle both sleepers and rail in the same set-up, increasing productivity.

Interchangeable arms

Interchangeable grab arms enable the SG60 to accommodate different types of sleepers.

Secure grip

The machine’s secure grip minimises the risk of damage to sleepers during maintenance, enabling their reuse.

Hydraulics

The Sleeper Grabber SG60 requires one double-acting hydraulics outlet (two hoses).

Safety features

The Sleeper Grabber has been designed with safety in mind – workers do not have to put their hands near the sleepers/grip.

Specifications

Related products

Pandrol rail clamps offer a reliable solution for the installation and maintenance of long welded rails, compatible with all types of transport and laying equipment.

Rail Grabber RG2500-RG3000-RG4800

A telescopic frame makes the Sleeper Layers compact and safe to operate. A unique, patented linkage system ensures that the centre of gravity does not change during sleeper spreading.

Sleeper Layer Attachments SL400/SL450/SL550/SL650/SL850

The Auto Master enables clipping to take place automatically, as part of a seamless process. With six to eight fewer people required on track to perform the operation, the machine has a major impact on site safety.

Automaster (For Sleeper Replacers SB40/SB60)

Pandrol’s SB40 and SB60 Sleeper Replacers are attachments designed to replace sleepers safely and efficiently.

Sleeper Replacer SB40 / SB60

Pandrol’s rail tongs are used to install and maintain continuous welded rail (CWR). The rail tongs clip automatically onto the rail being moved and are designed to be fastened to all types of hauling and rail removal equipment.

Rail Tongs

Pandrol have designed three types of track jacks: hydraulic, mechanical and obstructionless. They have all been designed for easy use, maximum operator safety and to be high performing in all working conditions.

Track Jacks

Once lifted, the rail can be moved with very low friction for the purposes of rail stressing. The resultant stress distribution is, therefore, optimised.