NABLA Evolution

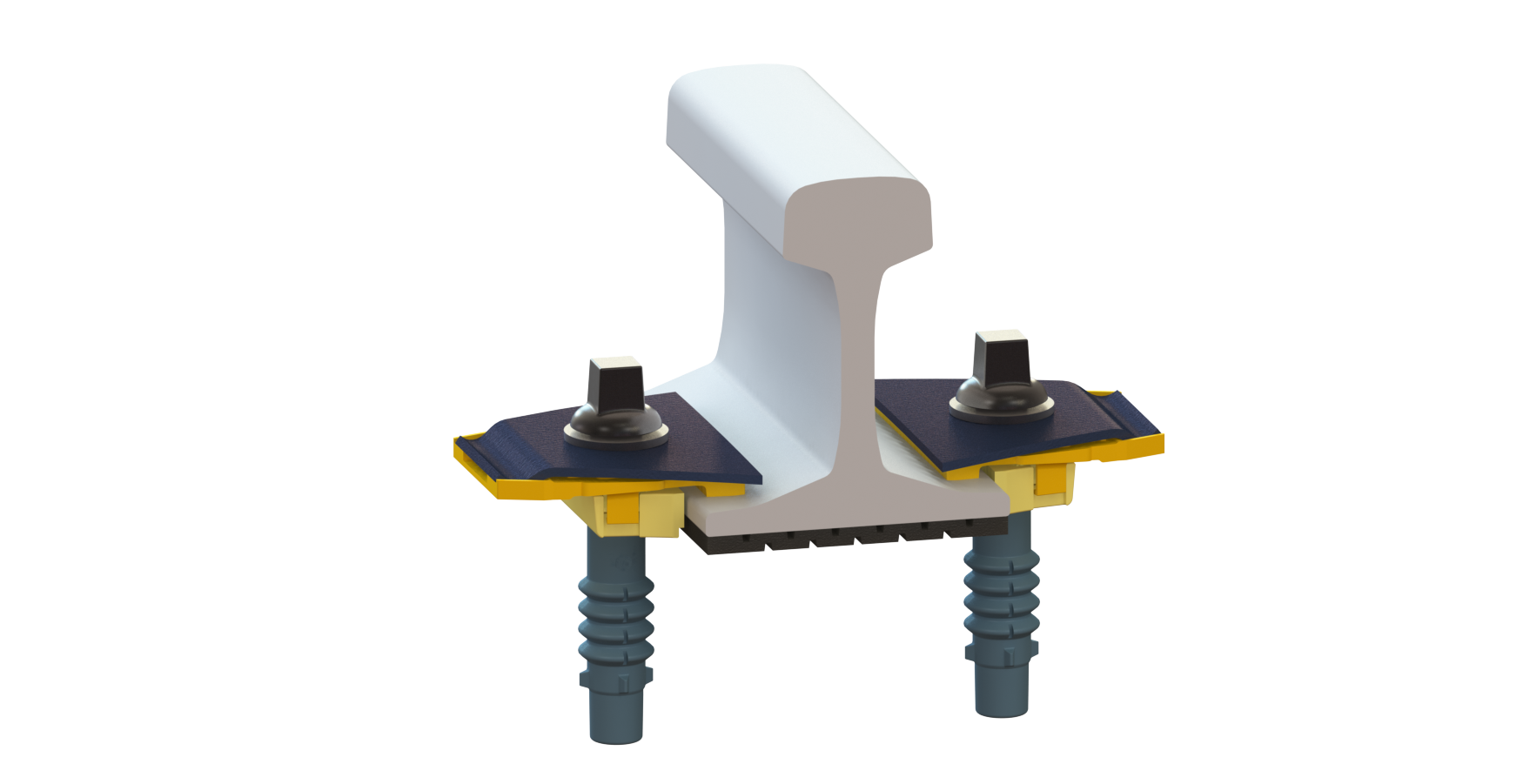

Increase the life expectancy of assembly components with a direct rail fastening system offering enhanced performance for tracks with tight radius curves. The Pandrol NABLA Evolution rail fastening has a track record for high performance spanning several decades and is recognised worldwide for its simple installation and low maintenance requirements.

NABLA Evolution Explained

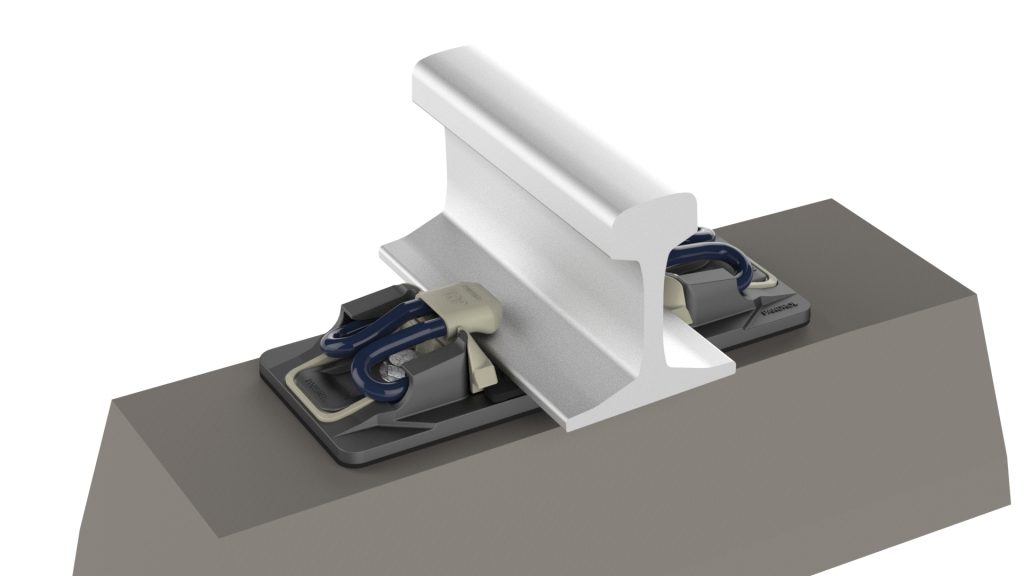

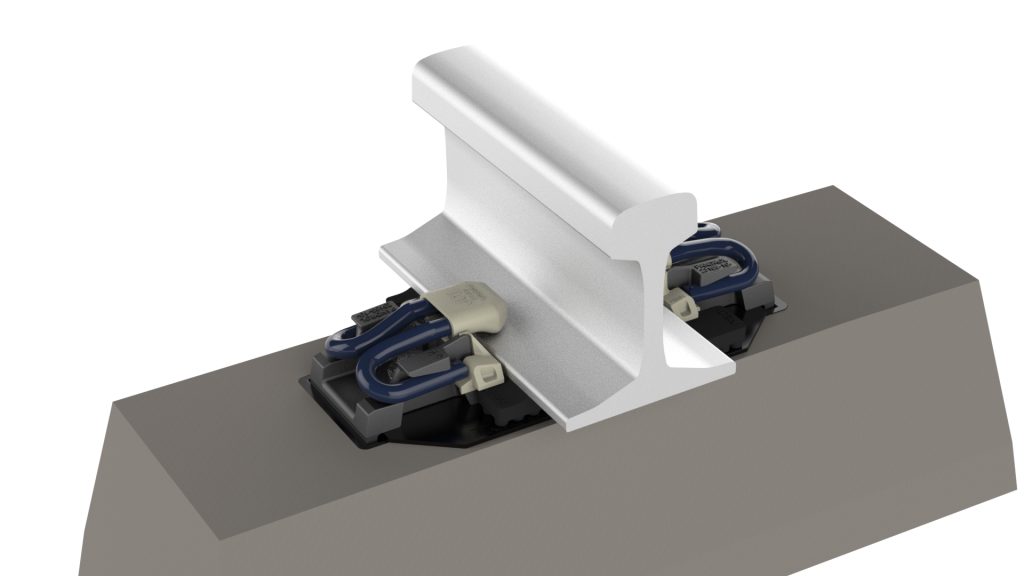

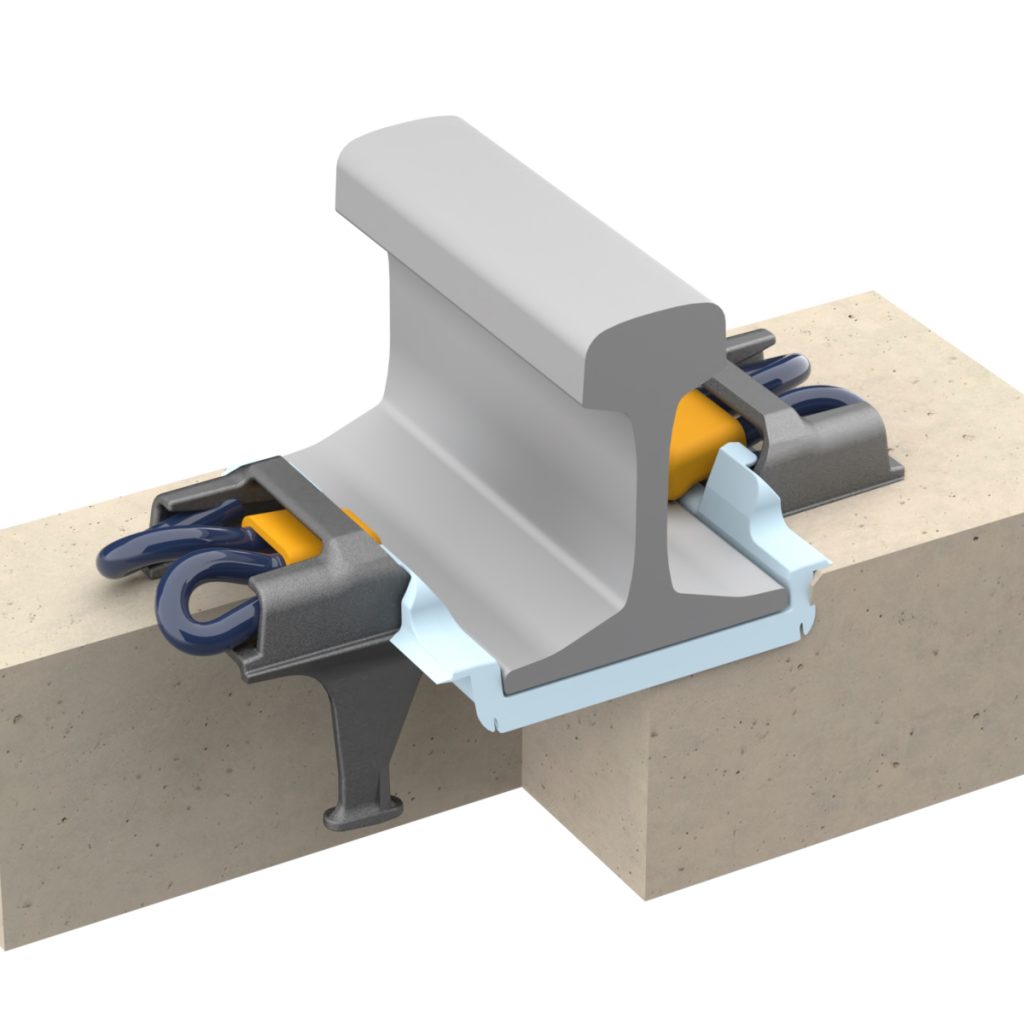

The NABLA Evolution rail fastening system enables simple installation and easy maintenance. It is designed to improve fastening performance in tight radius curves by maintaining the track gauge – boosting the life expectancy of assembly parts. The system is tightened by contact for consistent application of force on the rail foot.

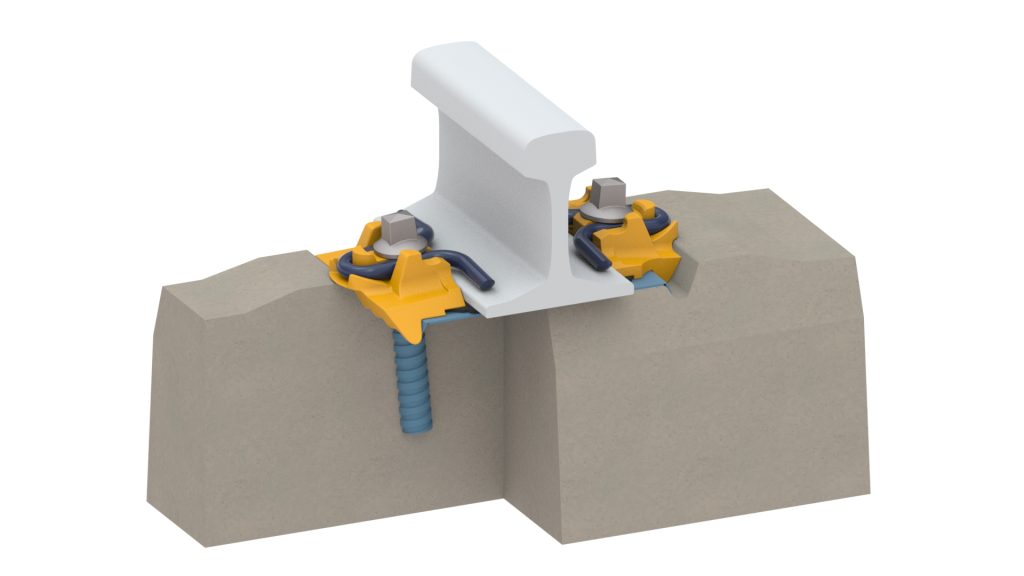

The system is most commonly applied to tram applications but is suitable for all types of tracks, including ballasted track and slab track with concrete sleepers of plastic baseplates. It is also available in a format compatible with bridges, reduced or zero toe load.

Choose the NABLA Evolution for improved electrical insulation and lateral force absorption, plus increased mechanical strength and versatility.

- Proven to maintain the track gauge

- Suitable for all track types, including heavy haul

- A durable, adjustable and versatile fastening solution

Downloads

Advantages of NABLA Evolution

Low maintenance

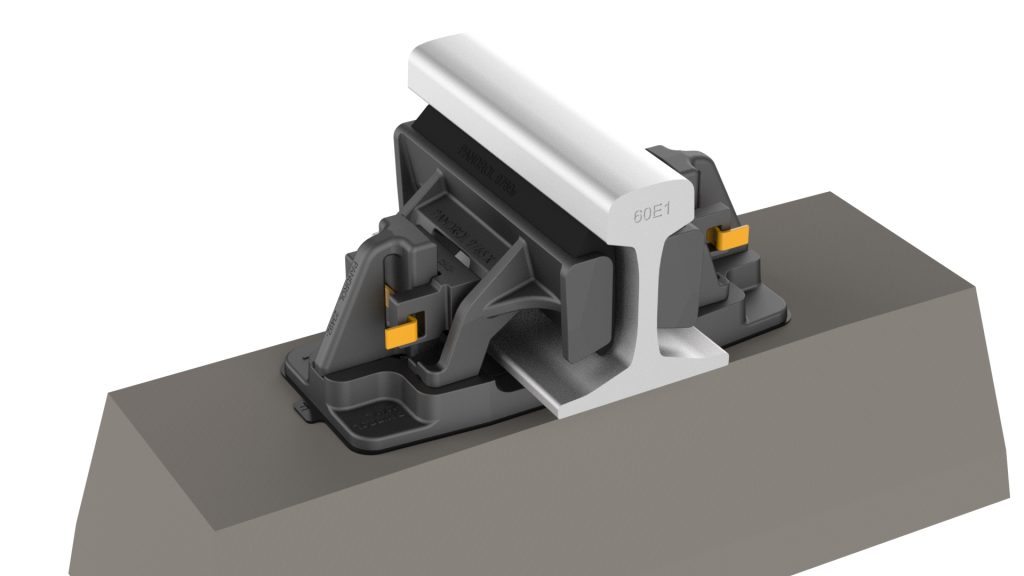

Keep track maintenance overheads low with the Pandrol NABLA Evolution fastening’s deep post insulator, which offers exceptional resistance to wear caused by lateral loads.

Simple installation

Save time, money, and labour with a track fastening solution that is simple and quick to install, while still offering high performance and durability thanks to its high-quality components.

Durability

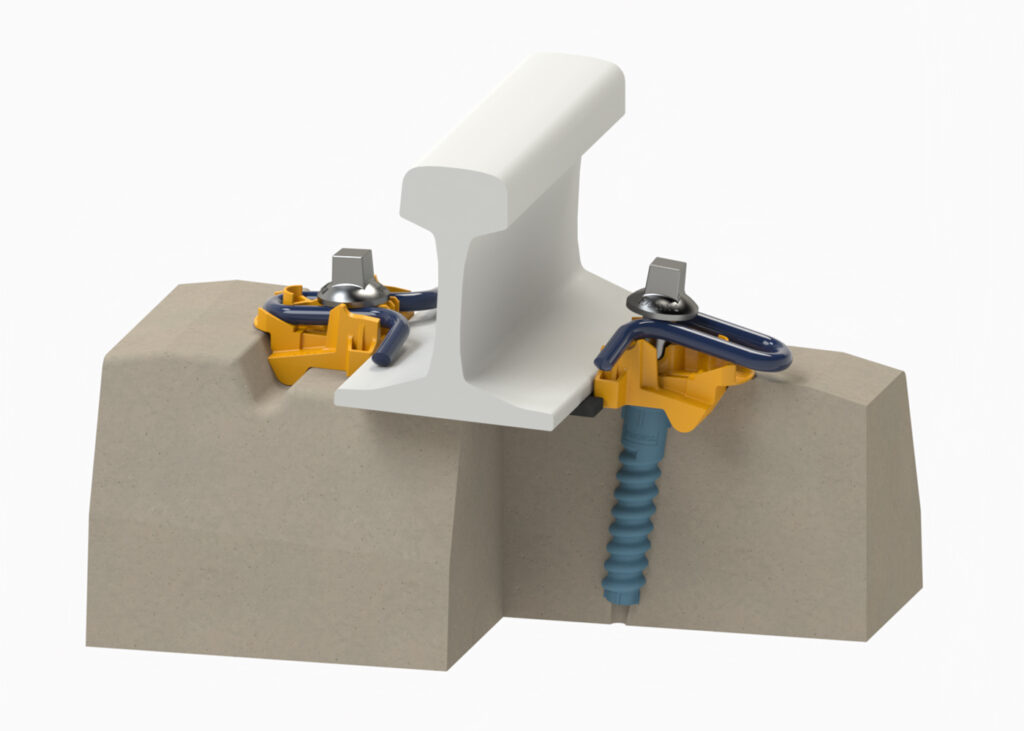

Rely on the NABLA Evolution’s unique construction to deliver durable results for years to come. The design utilises glass-reinforced material for high mechanical strength and lateral force absorption.

Superior insulation

Choose the NABLA Evolution rail fastening for its higher electrical insulation. The system is an efficient, effective, and safe option for tracks with tight radius curves – maximising the life span of all components.

Versatility

Benefit from the NABLA Evolution’s versatile nature. The system has been adapted for compatibility with all types of rail, including grooved, vignole, industrial, and AREMA. It is available in formats suitable for ballasted and slab tracks.

Adjustability

Achieve a good level of lateral adjustment via the NABLA Evolution’s insulators, which are optimised for fine gauge tuning. This adjustability aids in increasing the lifespan of rail components.

Technical features of NABLA Evolution

High clamping force

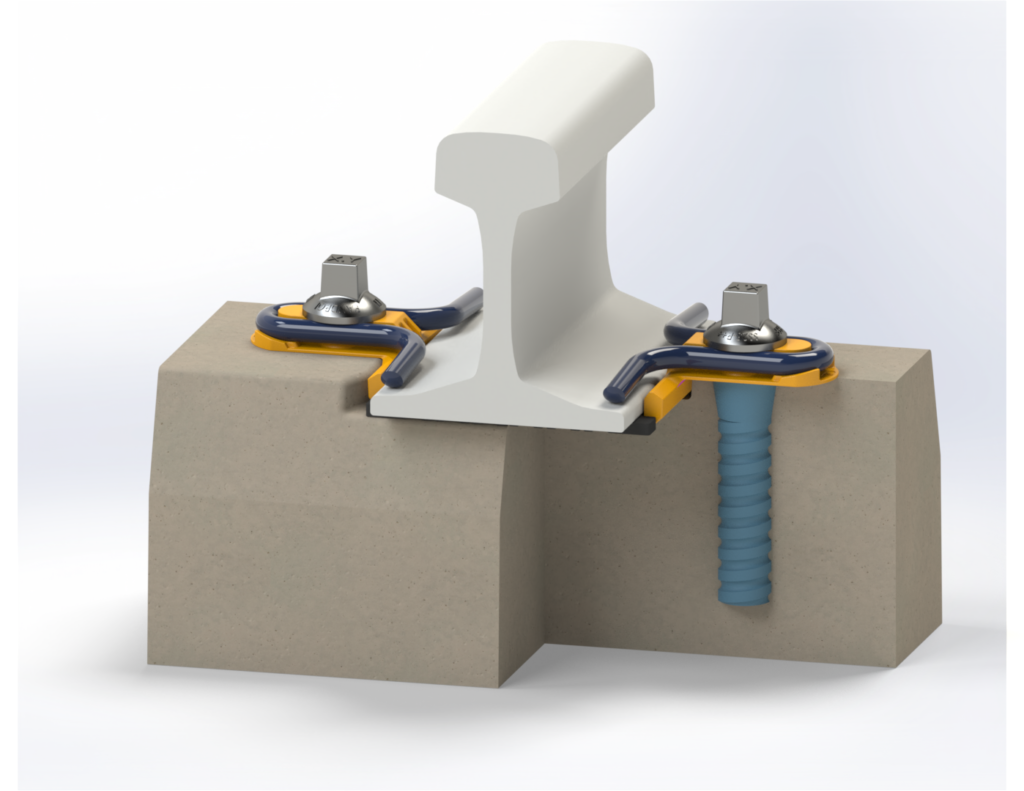

Prevent rail roll with the high clamping force of the NABLA Evolution. The fastening’s anchor screw is tightened to the contact, ensuring a consistent application of clamping force on the rail and a large range of torque.

Lateral force absorption

Choose a fastening solution with a high level of mechanical strength and good lateral force absorption. The NABLA Evolution fastening is constructed with specialised glass-reinforced material for durability and high performance under pressure.

Optimised coach screw

Achieve toe load automatically once the NABLA Evolution’s coach screw is tightened to contact. The screw offers a large acceptable torque range of between 250 and 400 Nm, making it versatile.

Adjustable insulators

Ensure a good level of lateral adjustment via the NABLA Evolutions insulators, providing excellent track gauge and alignment. Fine gauge tuning by 1.25mm increments, ±7.5mm per rail seat is achievable.

Electrical insulation

Achieve electrical insulation higher than standard NABLA systems with the NABLA Evolution’s enhanced capabilities. The fastening system provides electrical insulation of over 10 K Ohms (EN13146-5:2012).

Options for rail pads

Apply the NABLA Evolution fastening system to any rail system or environment, with a choice of rail pads from 35 MN/m for tramways, up to 400 MN/m and above for heavy haul applications and tight curves.

Related products

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip