Porttech product overview

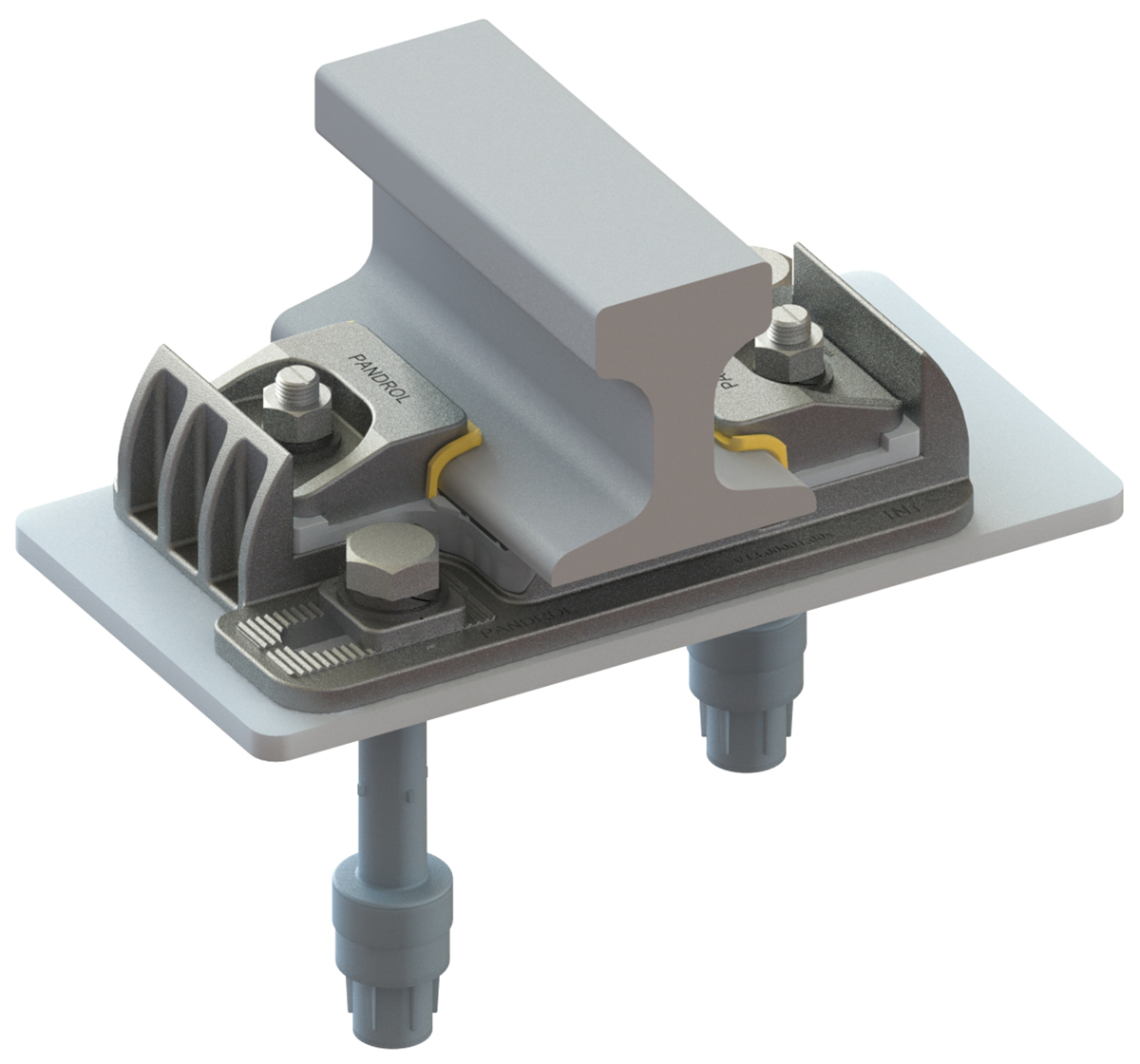

The Porttech fastening system features a wide range of fine rail adjustment in a compact assembly.

- A baseplate with lateral restraining features is anchored securely to the base structure, while the rail is clamped down by applying torque to independent screws.

- The rail is encased by a thermoplastic pad underneath and insulator pieces under the clamp components, to provide electrical isolation.

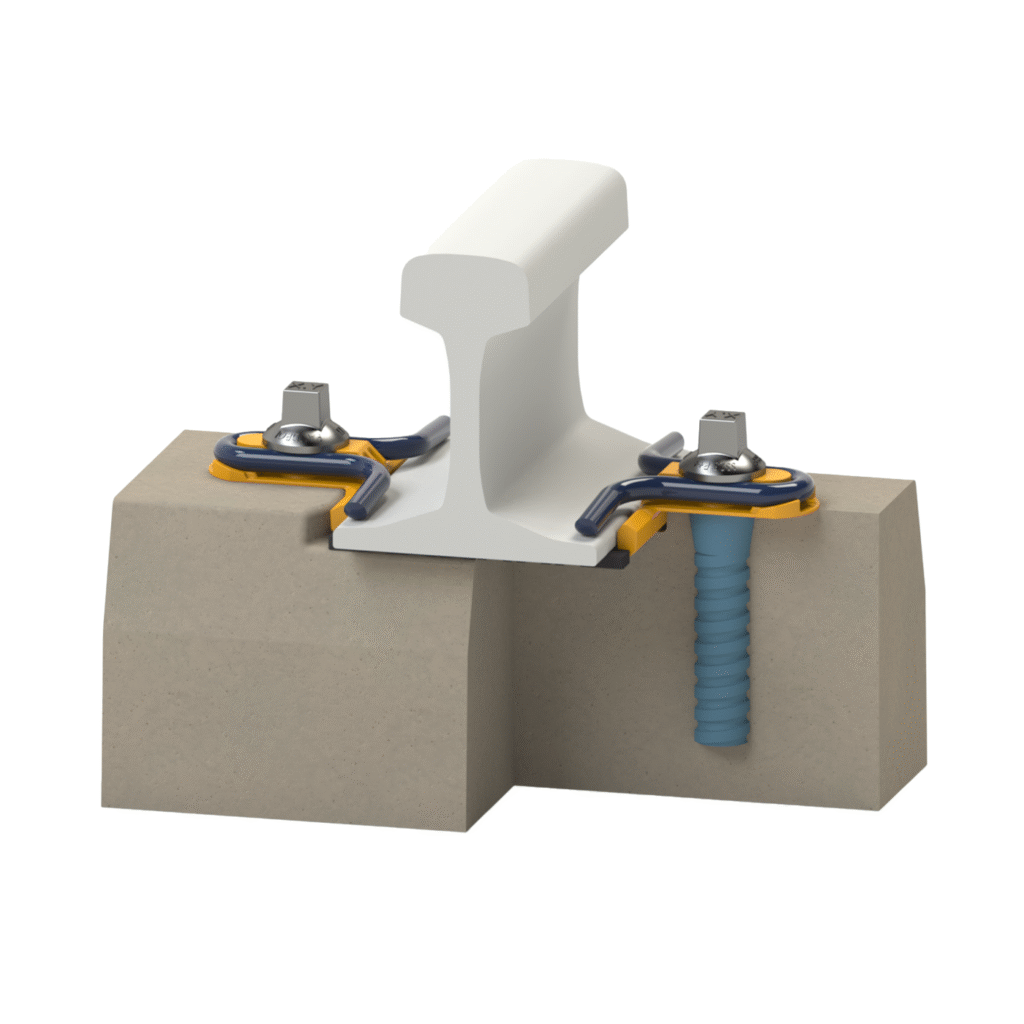

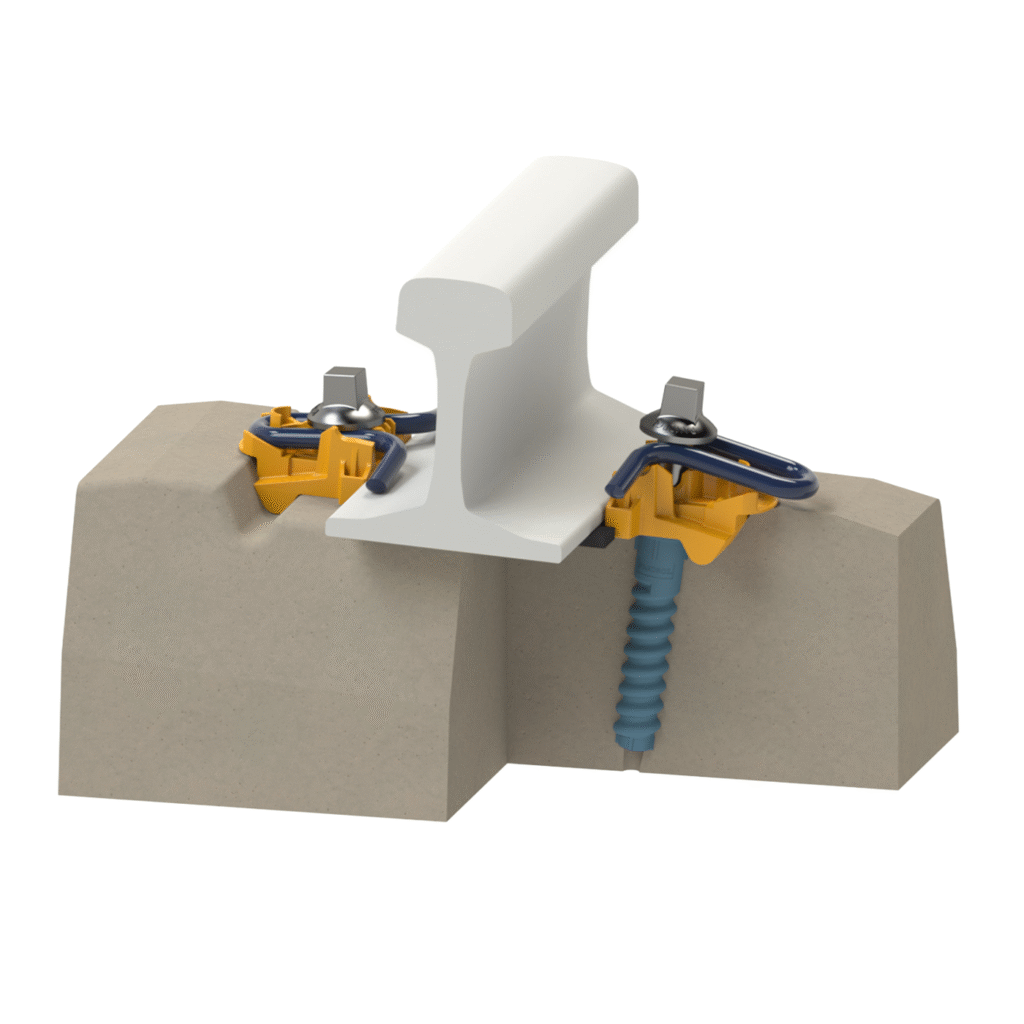

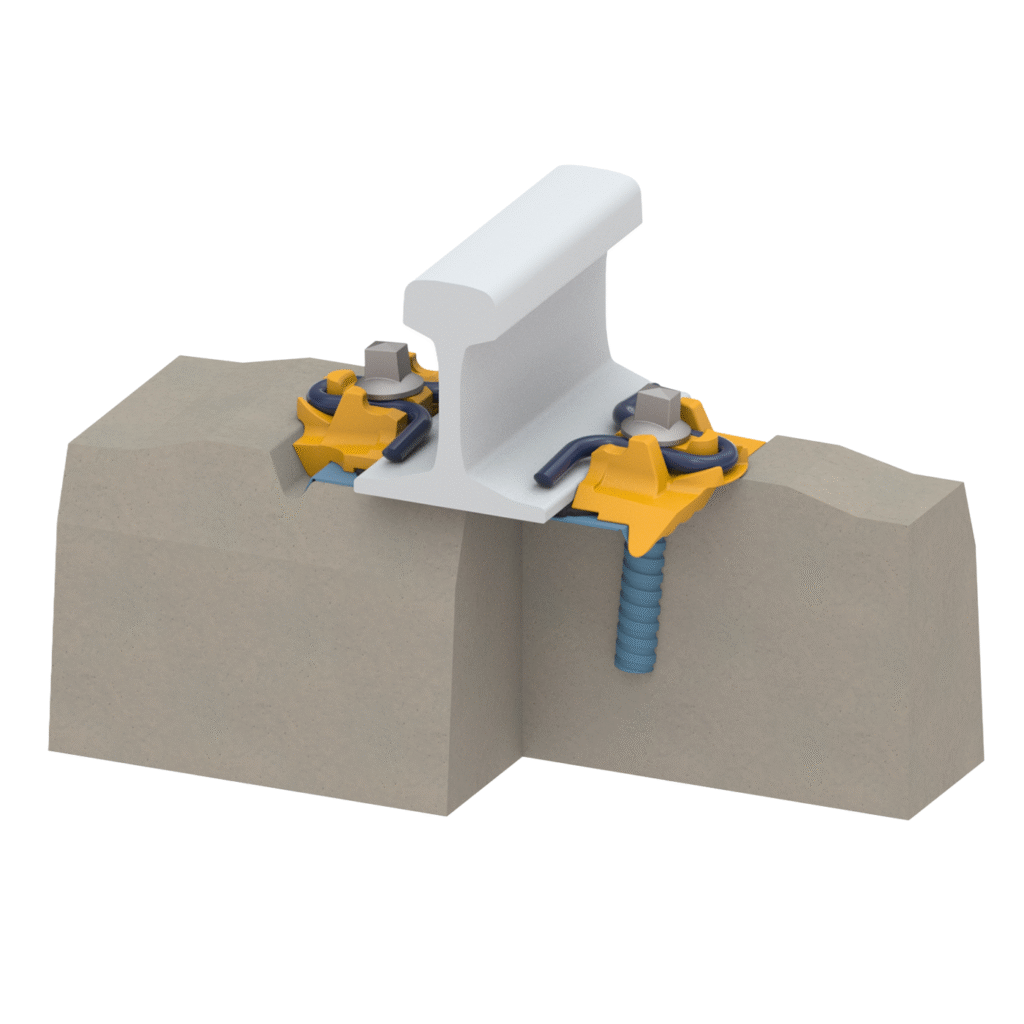

- Porttech is available in a range of design variations to suit different civil structures.

Downloads

Benefits of the Porttech

Vertical adjustment

Porttech can be vertically adjusted to accommodate any settlement or rail wear without compromising the integrity or compact nature of the fastening assembly. Vertical adjustment is simple and safe.

Flexibility

A large degree of lateral adjustment provides flexibility when there is heavy wear of the rail heads, and this is achieved without the need for any additional components.

Compact design

Porttech’s compact design and low profile ensure that the fastening does not interfere with the crane’s moving parts at wheel level.

Easy maintenance

Inspection and maintenance are quick and easy because all of Porttech’s components are visible. No special hand tools are needed.

Reduced installation time

The pre-assembled baseplate units reduce installation time and ensure efficient maintenance – particularly important in a busy port environment.

Versatile

Design variations without baseplates are ideal for use with lighter cranes on concrete or steel base structures, increasing Porttech’s versatility.

Technical features of Porttech

Vertical adjustment

Porttech can be adjusted vertically by undoing the rail clamp screws, lifting the rail in situ, and sliding shims with slots under the rail pad. Further vertical adjustment can be done in the same way under the baseplate.

Lateral adjustment

Lateral adjustment is achieved by moving the serrated slots of the baseplate along the fixed anchor points. These are intentionally installed offset, to maximise the range by spinning the baseplate through 180 degrees.

Low profile

Porttech has been designed with a particularly low profile for a fastening system.

Electrical isolation

Electrical isolation is provided by a thermoplastic pad underneath the rail and insulator pieces under the clamp components.

Visible components

None of the components on the Porttech rail fastening are hidden from view.

Pre-assembled units

The assemblies can be delivered to site as captive units

Design variations

Porttech fastening assemblies can be supplied with or without cast-iron baseplates.

Related products

The Nabla fastening is developed by our fastenings team in Douai, quickly becoming the standard system for tramway netwoks across Europe in the form of Nabla Tram, with Nabla Evolution offering high electrical insulation and lateral force absorption for concrete sleeper in ballasted track.

Nabla

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the in-service position.

SD (Safe Driven)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.