Pandrol Heavy Haul Solutions

Keeping heavy haul moving

For more than 40 years, Pandrol has led the heavy haul rail industry with cutting-edge solutions for axle-loads of up to 40 tonnes. Our products and technical expertise have shaped all the major heavy haul railways in the world.

We design our solutions with availability, reliability and sustainability at the core.

Expertise you can rely on

Our products and equipment have been developed to withstand a huge variety in environmental and climatic conditions. Our customers, operating in Africa, Australia, Brasil, Canada and the USA, all have different working environments, climates and local conditions which gives us a unique understanding of the Heavy Haul needs across different territories.

Join us at IHHA

We will be at the International Heavy Haul Association (IHHA) Conference 2023!

Join our experts for the technical workshop on 27-28 August, followed by an exhibition of our latest heavy haul solutions at the main conference on 29-31 August. Details of our presentations are below

Pandrol Presentations at IHHA

Monday 28th August / 08:40 / Jamie Pogson

Pandrol’s Under Sleeper Pads: Maximising the Sustainable Lifetime Value of Heavy Haul Tracks with Recycled Rubber

Tuesday 29th August / 13:30 / Frédéric Delcroix

Real Time Sound Analysis When Preheating For Aluminothermic Welds

Wednesday 30th August / 09:55 / Marco Aurelio Stail Filho

Unlocking the Power of Sustainability: Pandrol’s Commitment to a Greener Heavy Haul Industry

Wednesday 31st August / 14:55 / Lionel Winiar

Improvement of Aluminothermic Weld Performance With Innovative Air Quenching

Heavy Haul Solutions

Our Sustainable Resilient systems are made from 90% recycled tyres, they increase track elasticity by increasing the contact area between ballast and sleeper, extending the life of the track, lowering our customers’ carbon footprint and reducing life-cycle cost.

Sustainable Resilient Systems

Our welding product helps welders get more done, quicker. Our accessories and equipment also make the welds less manual and more ergonomic, improving the overall quality and safety of rail infrastructure.

Our Pandrol Connect is a mobile app designed to support aluminothermic welders through the weld process, capture live data about the weld, save time and improve the traceability of welds for contractors and rail network operators.

Aluminothermic Welding

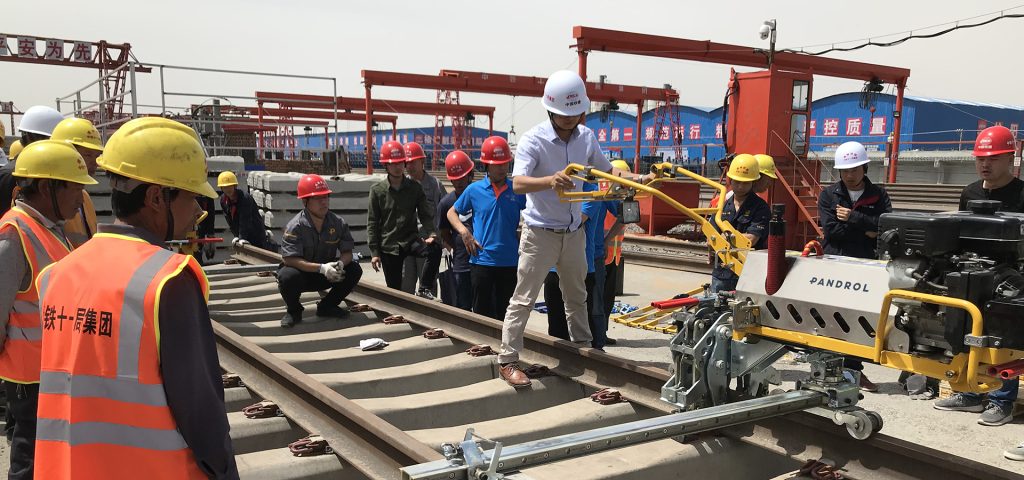

Our fastening systems are easier to install, require less maintenance and are proven to last longer than our competitors’. And our range of clipping machines automate the whole clipping process, making it fast and stress-free.

Fastening Solutions

Our products

Pandrol Under Sleeper Pad (USP) solutions reduce maintenance requirements, increase track quality and provide vibration attenuation to Ballasted Track.

Under-Sleeper Pads

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

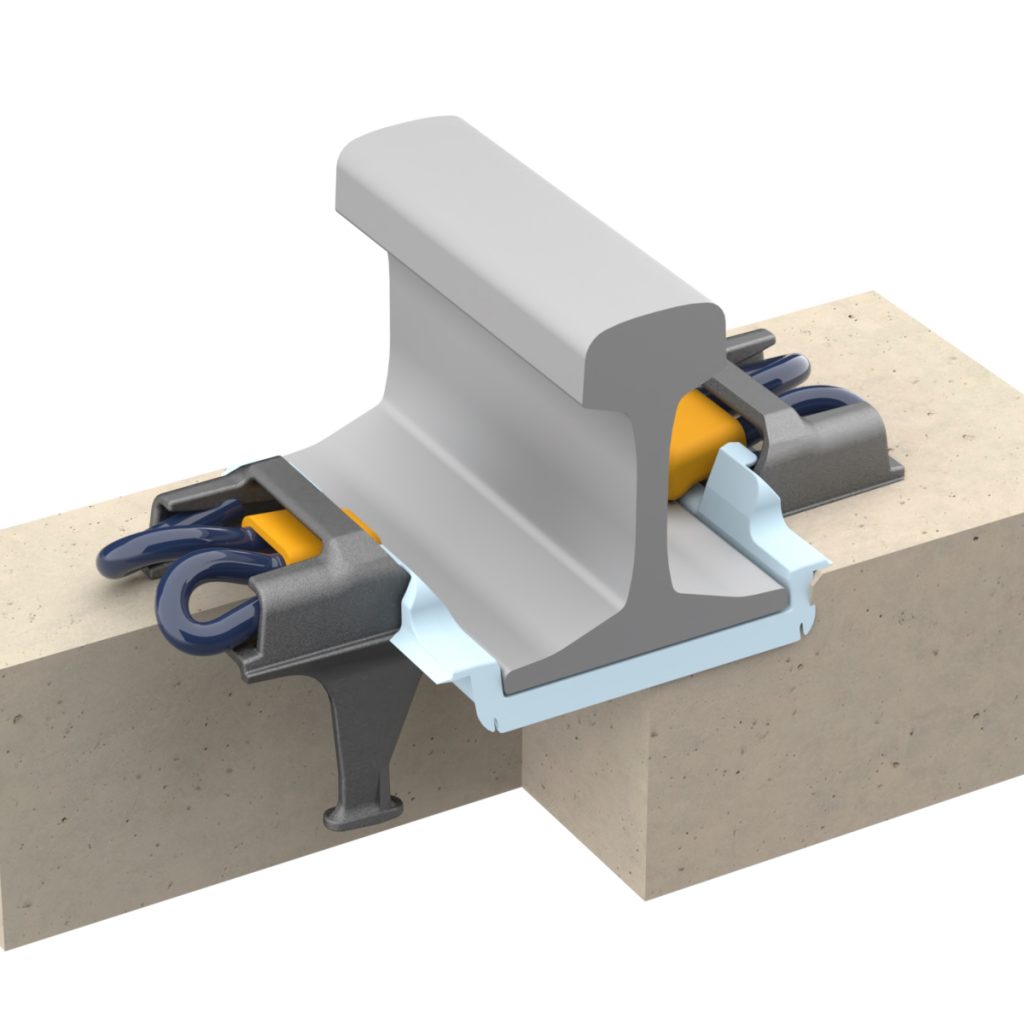

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

This robust and reliable self-propelled machine now has an EU Stage 5 diesel engine from Hatz and a new intelligent control system. The machine installs 4 clips simultaneously across two rails and has a sleeper lift function for new construction projects.

Clip Driver CD400SP IQ

Pandrol’s original design e-Clip systems are manufactured to one global standard and are produced worldwide at Pandrol’s various manufacturing facilities.

e-Clip

Our vignole rail welding processes equip the user to perform new welds as well as wide-gap and head-wash repairs.

Vignole Rail Welding

AutoSeal® moulds are Pandrol’s newest aluminothermic welding innovation that streamlines the welding process.

i+seal moulds (formerly AutoSeal®)

Manufactured specifically for excavators weighing 10 to 16 tonnes, the Hy-Rail attachment offers stability and flexibility when working on track. All movement is controlled from the driver’s cabin, and the hydraulics work without the need for additional swivel implements

Hy-Rail 10-16T

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.