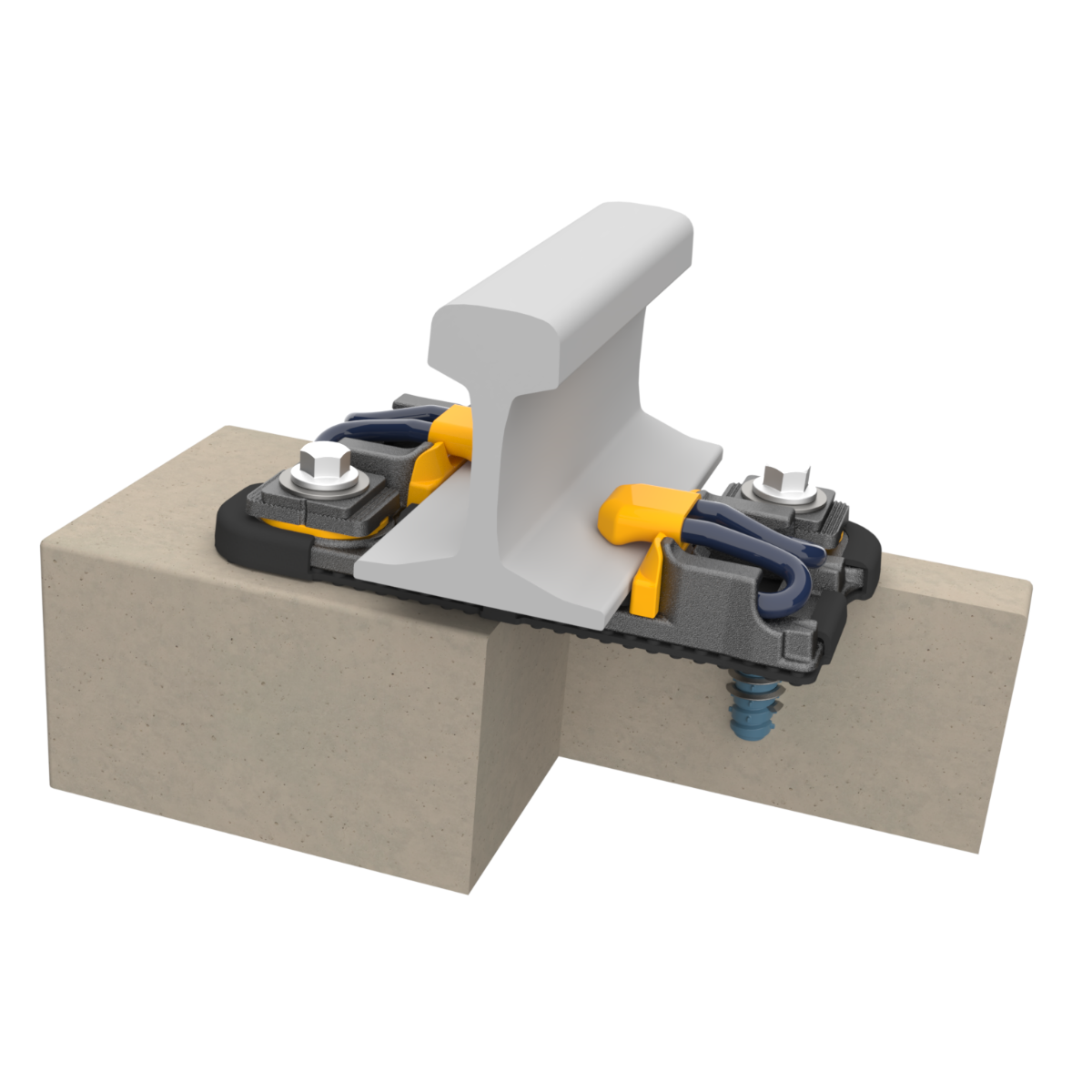

Fastclip Baseplate product overview

The baseplate offers a very large range of both vertical and lateral adjustment in a configuration where these adjustments can be made very quickly and easily and with a minimum of additional components required.

- The Pandrol Fastclip Baseplate is designed for use on either pre-cast concrete elements, direct pour concrete construction or steel structures.

- The system is designed for efficient installation and maintenance to offer railway operators maximised rail infrastructure 'up-time'.

Downloads

Benefits of the Fastclip Baseplate

Low maintenance

Designed for high levels of mechanisation and automation through track installation and maintenance, delivering faster maintenance and high levels of adjustment

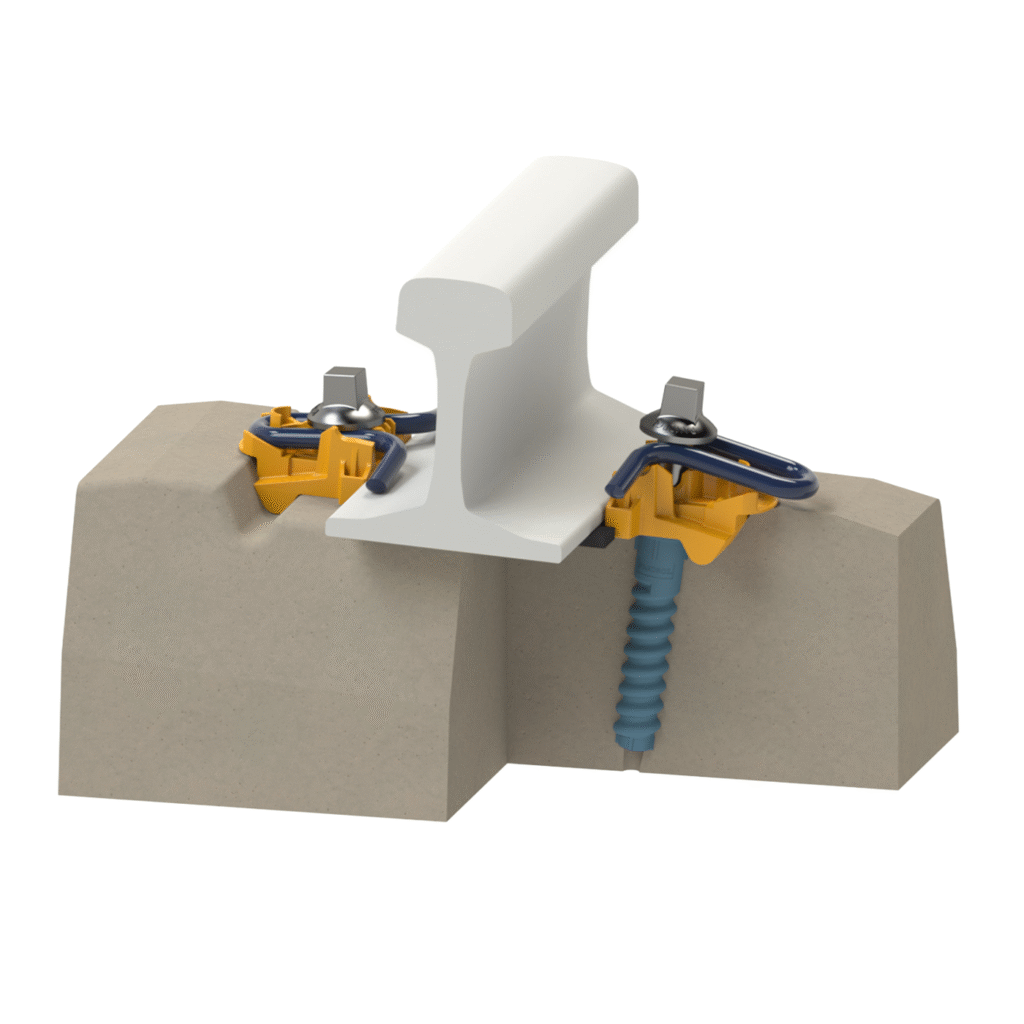

Easily adjustable

Lateral adjustments can be made quickly and easily. No components need to be exchanged and there is no need to disassemble the fastening system.

No size of increment limitation

There is no limit on the size of increment in which lateral adjustments can be made within the +/12 mm range. Absolute lateral position of the rails can be set at both the track build stage and also during track maintenance activities

Simple

Vertical adjustments can normally be made without the need to disassemble the fastening system fully. Loosening the anchors is sufficient to allow all but very large adjustments to be made simply

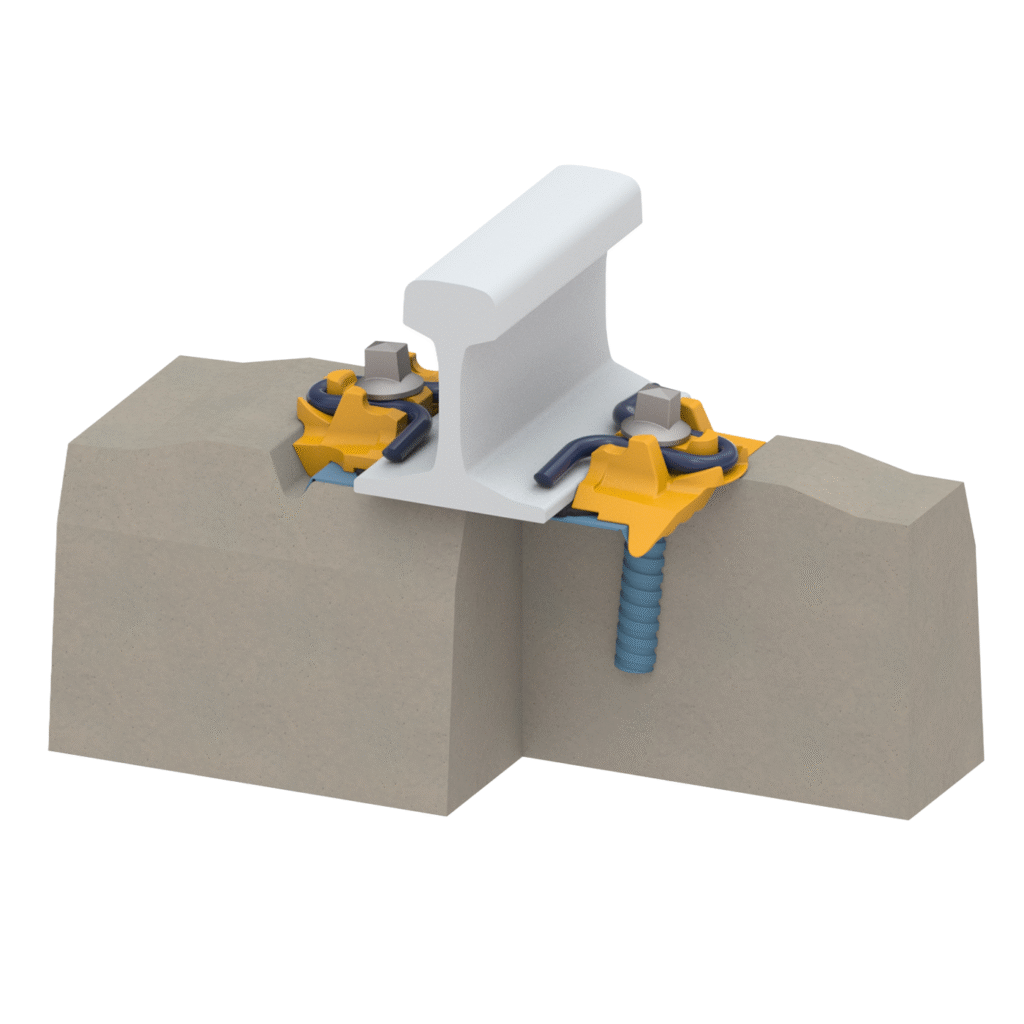

Easily vertically adjusted

No parts need to be exchanged or added to make vertical adjustments, other than the correct shims and the need for longer bolts at large intervals within the 70mm vertical adjustment range

Technical features of the Fastclip Baseplate

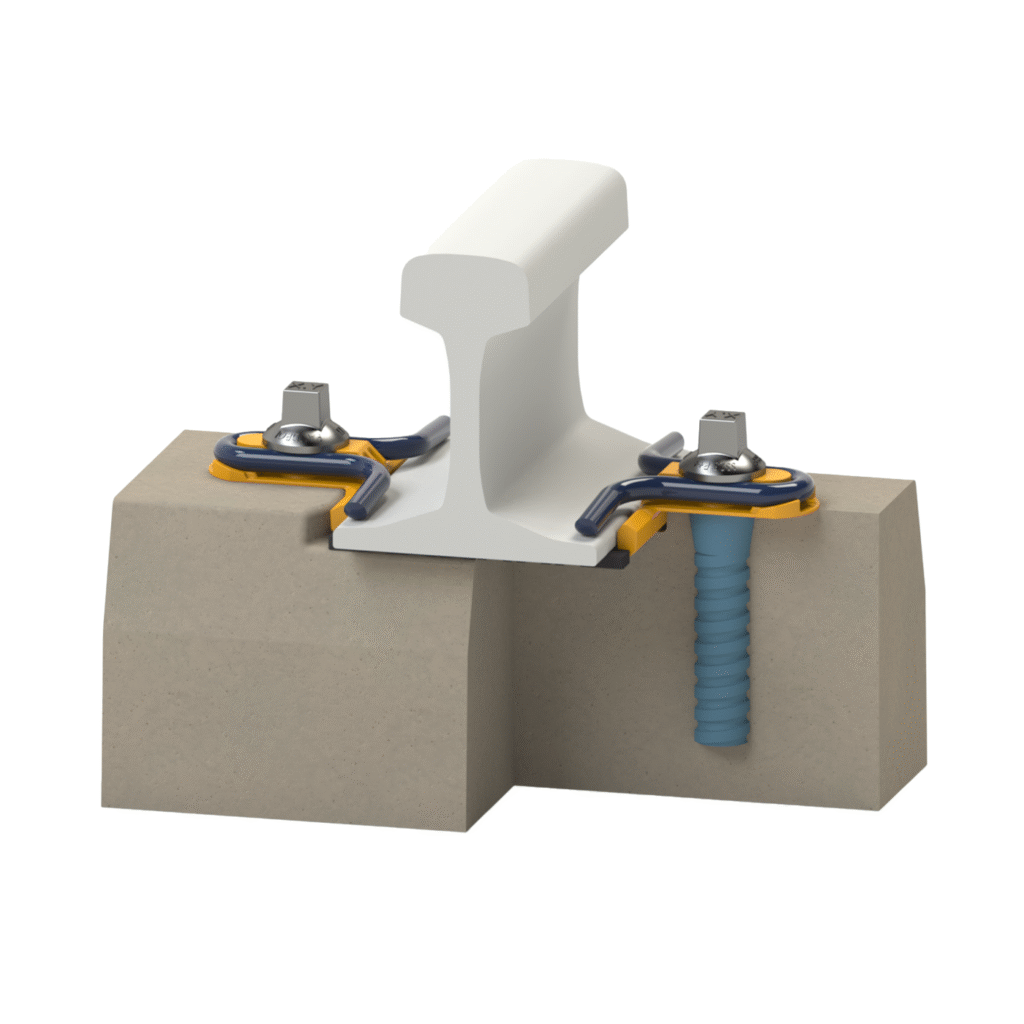

Pre-assembled

Can be supplied as pre-assembled units with the clips in the parked position.

Lateral adjustments

Provides lateral adjustments in the range of +/-12 mm per assembly (or +/-24 mm on track gauge)

Vertical adjustments

Provides vertical adjustment up to +70 mm, by means of fitting shims underneath the assembly

Low rolling noise

Developed to provide a stiffness characteristic that results in low rolling noise

Used on bridge and viaduct structures

Available in low toe load or zero longitudinal restraint (ZLR) configurations. These are for use on bridge and viaduct structures

Related products

The Nabla fastening is developed by our fastenings team in Douai, quickly becoming the standard system for tramway netwoks across Europe in the form of Nabla Tram, with Nabla Evolution offering high electrical insulation and lateral force absorption for concrete sleeper in ballasted track.

Nabla

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the in-service position.

SD (Safe Driven)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.