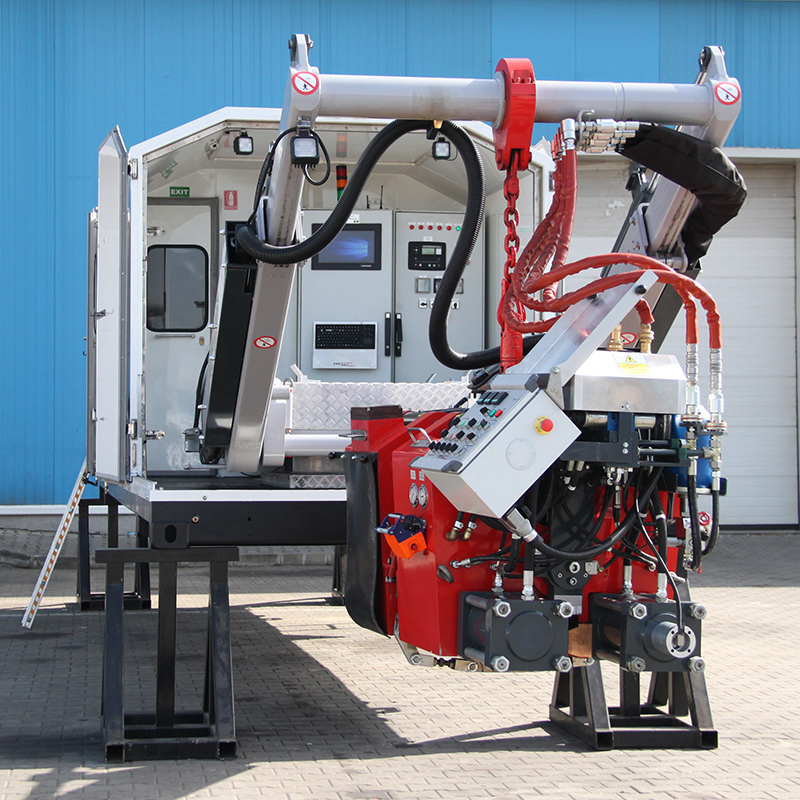

Pandrol’s Omega Grinder Explained

The Omega Grinder is specially designed for grinding the top and sides of railheads and the frog with precision and accuracy. Created with modular sections, workers and operators can effortlessly and safely disassemble and transport the grinder. The Omega is versatile and quick, making it the ideal tool for maximising uptime and keeping costs low by reducing track maintenance operations and requiring less manpower.

- A superior rail grinding product designed for accuracy and precision

- Helps to keep costs and downtime low

- Easy and safe to assemble, disassemble and transport

Downloads

Advantages of the Pandrol Omega Grinder

Ergonomic operation

Support safe and easy grinding with the Pandrol Omega Grinder. Its modular, ergonomic design supports safer and more comfortable operation for rail workers by ensuring low vibration during use.

Safety

Alternate between grinding rails on either side of the track effortlessly and safely thanks to the Pandrol Omega Grinder’s unique, versatile design, which makes it compatible with rail switches, frog sections, and the rail profile.

Speed and efficiency

Speed up grinding operations without sacrificing accuracy and quality. The Omega Grinder delivers quick, precise grinding thanks to its powerful 14Hp hydraulic engine and easy operation, keeping track downtime to a minimum.

Cost-effectiveness

Cut costs thanks to reduced track downtime. The Omega Grinder is highly cost-effective due to both its efficient operation and its multiple uses. Grind the frog segment, switches, and profile of the rail with just one tool.

Versatility

Extract even more added value with the Omega Grinder. This versatile tool isn’t only suitable for grinding multiple rail sections, its hydraulic power source is also compatible with the wide range of Pandrol hydraulic tools.

Technical Capabilities of the Omega Grinder

Modular design

Ensure high performance and user comfort thanks to the Pandrol Omega Grinder’s unique modular build. The product consists of five modular segments that provide enhanced user ergonomics, especially when installing and removing the machine from the track.

Grinding stone options

Switch between grinding tasks as required with the Omega Grinder. Simply swap between the two provided grinding stones to perform different grinds and see the tool’s full versatility in action.

Adjustability

Grind rail profiles with extreme precision thanks to the Omega Grinder’s advanced adjustability, which provides an impressive range of 10°/+90.

Power source compatibility

Ensure a versatile range of track maintenance options thanks to the Omega Grinder’s compatible power source, which is designed to work with a range of Pandrol hydraulic tools.

Related products

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The revolutionary i+align automatic aligner has been designed to transform rail welding through precise, automated rail alignment.

i+align

Designed to screw/unscrew all types of bolts and drill holes in wooden sleepers, this high-efficiency tool is powered by a specially designed engine that ensures accurate, quick, reliable operation.

Impact Wrench Master 35

The equipment can be used for normal gap, wide gap and head wash repair (HWR) welding.

i+cool

Performing checks and adjustments is an important part of the welding and maintenance process, particularly on the ends of rails.

Straight Edges RAP1000, RB500, RB700 and RB1000

Designed to operate with the included battery-operated non-impacting drill, the simple chuck attachment allows easy installation of the shear so it is quickly operational on the track.

Compact Shear B-M-VIR

Excess metal remaining above the rail head during welding was traditionally removed manually with a hammer and chisel. The Weld Shear Hand Pump automates this process and reduces the risk of damaging the rail.

Weld Shear Hand Pump EPM2

quipped with a fail-safe braking system and supplied with a detachable brake and push handle, the Rail Lorry has a stand-alone, load-bearing rolling platform for use on track

Rail Lorry PL01 and PL01.5

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

Pandrol offers a complete mobile flash butt welding plant hire service for rail companies, to complement our aluminothermic welding solutions in India. The service involves providing access to a flash butt welding machine, along with a trained team of operators to carry out the welding process to a high standard.

Flash Butt Welding

During aluminothermic welding, a deadhead of excess metal remains above the rail head. This was traditionally removed manually with a hammer and chisel. The Monobloc Electrical Weld Shear automates this process and removes the risk of damaging the rail.

Monobloc Electrical Weld Shear EME1/EME2

During aluminothermic welding, excess metal remains above the rail head. This was traditionally removed manually with a hammer and chisel.