SKL product overview

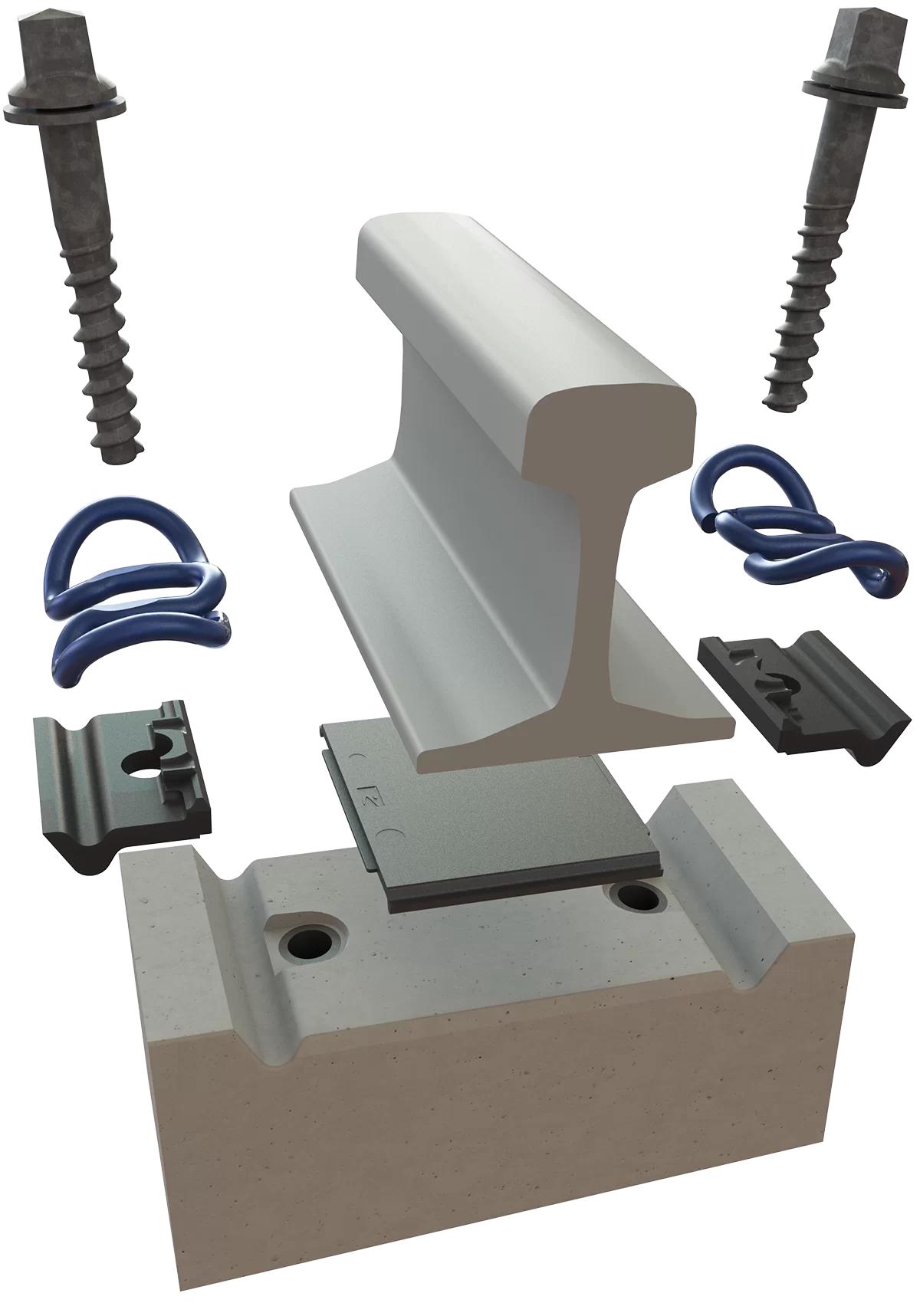

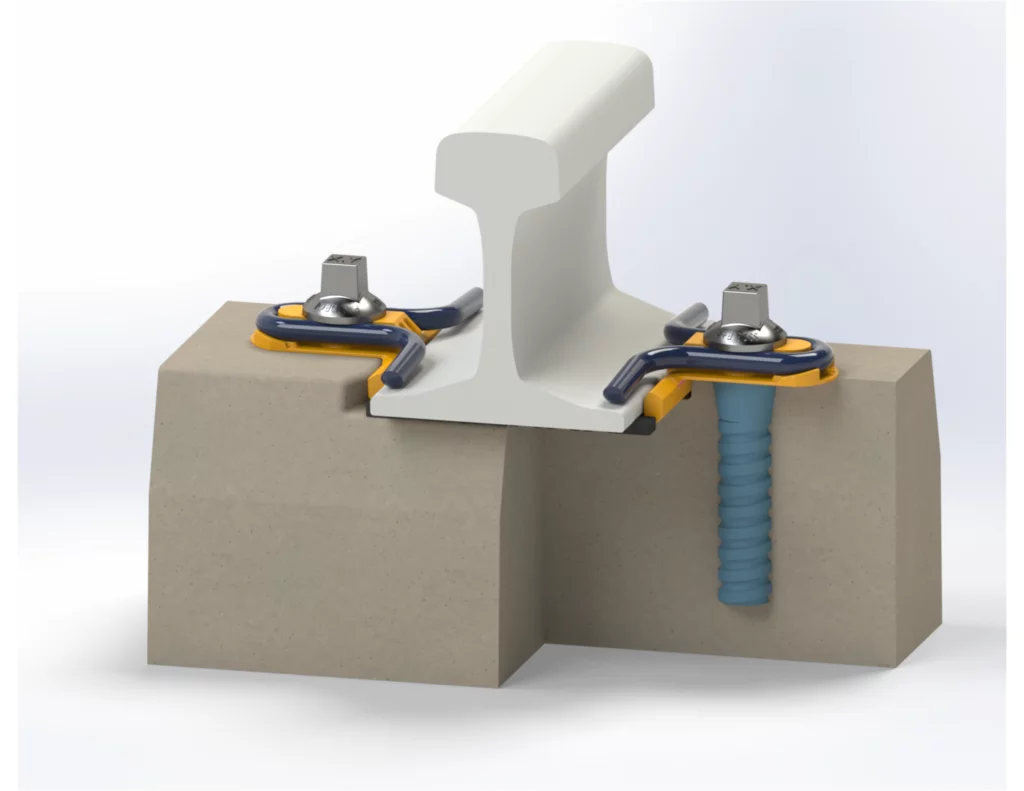

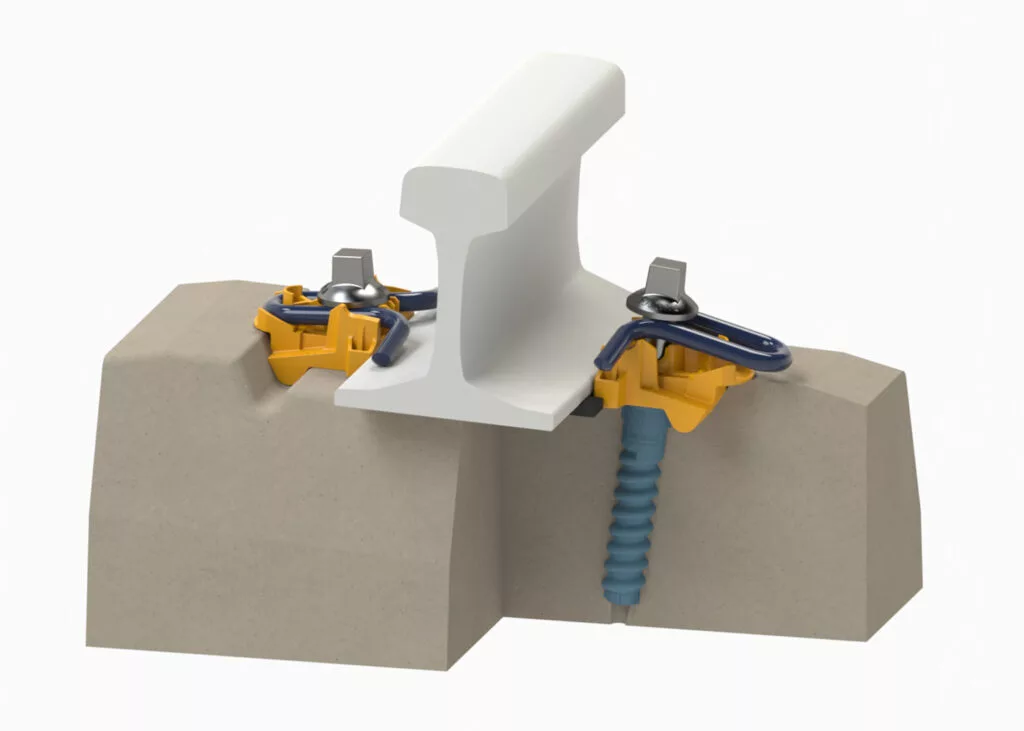

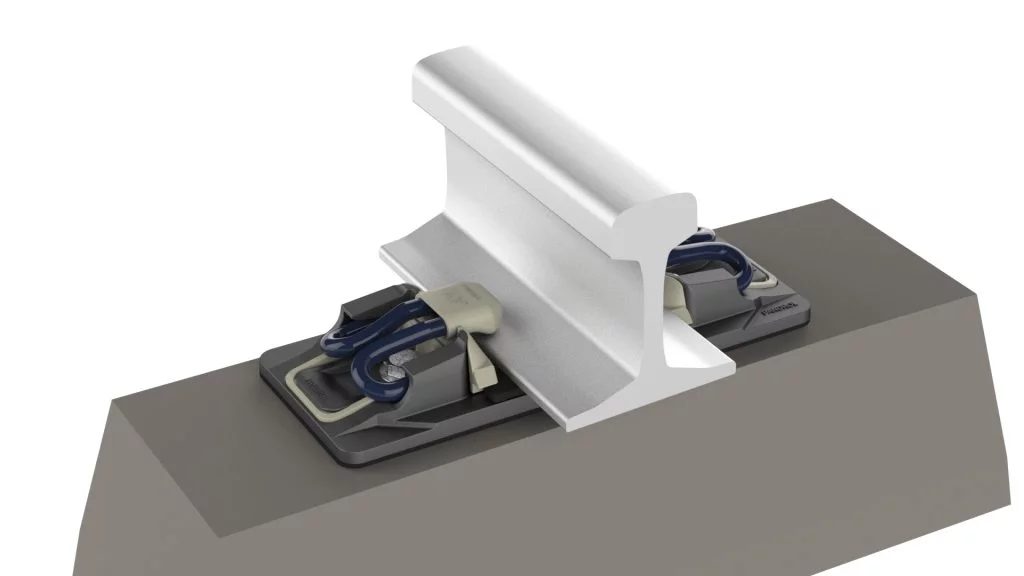

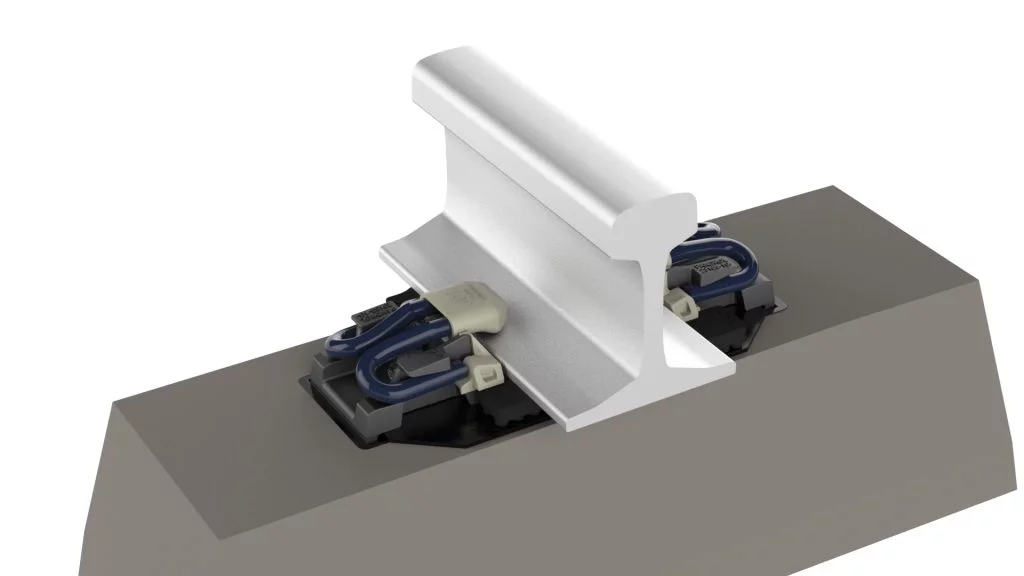

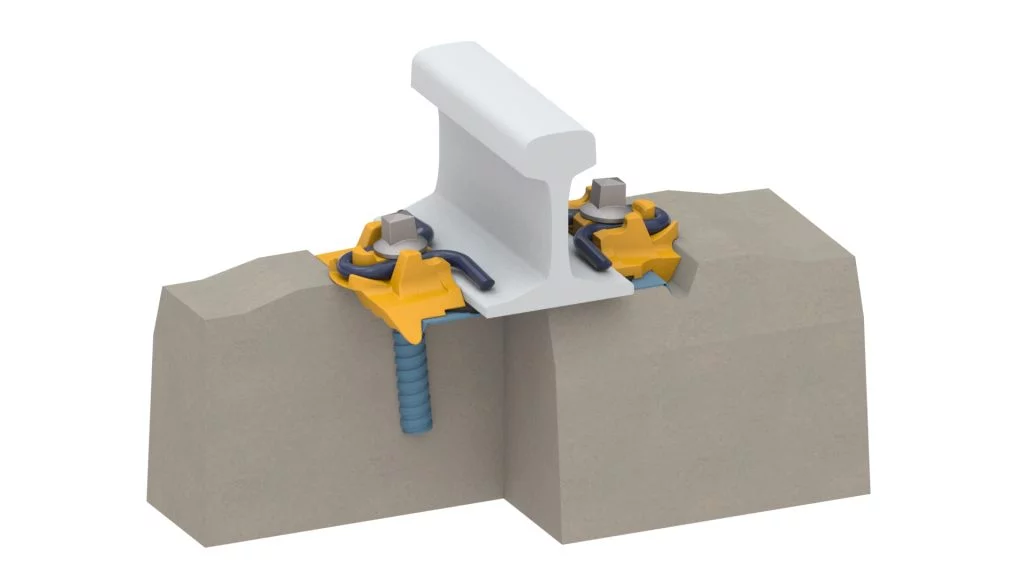

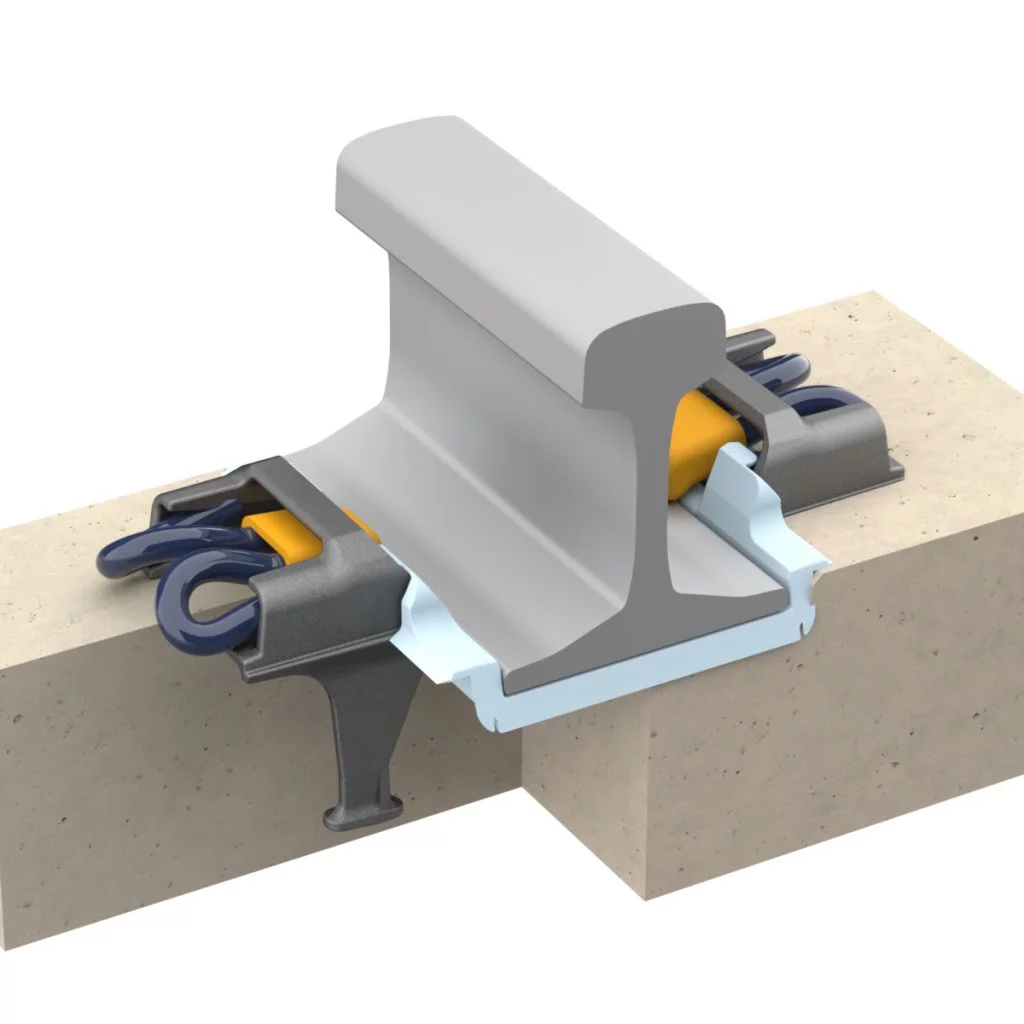

The rail seat assembly is typically made up of two tension clamps (SKL clips) on top of angled guide plates on each side of the rail.

- The guide plates are located in recesses on the concrete surface, securing the rail horizontally and transferring lateral loading to the sleeper

- A pad under the rail provides layer to attenuate impact and electrical resistance

- Everything is held down with screws in concrete dowel inserts

Downloads

Benefits of the SKL

Adjustable

The gauge can be adjusted simply by swapping components. This removes the need for different sleepers when gauge widening or redemption is needed.

Quick installation

Captive fastening reduces handling and, as a result, the risk of losing components. Efficient installation and maintenance save time and money.

Money saving

All components are replaceable (even the concrete dowel), which limits maintenance costs to the affected components rather than the whole sleeper.

Versatile

The ability to vary clamping force means that longitudinal restraint can be changed where necessary for specific areas of the track.

Controls track stiffness

Adjusting fastening stiffness allows overall track stiffness targets to be met, even when these change over time.

Increases track quality

The overturning stop keeps the rail located securely and protects the clips from overstretching and ultimately failing.

Technical features of SKL

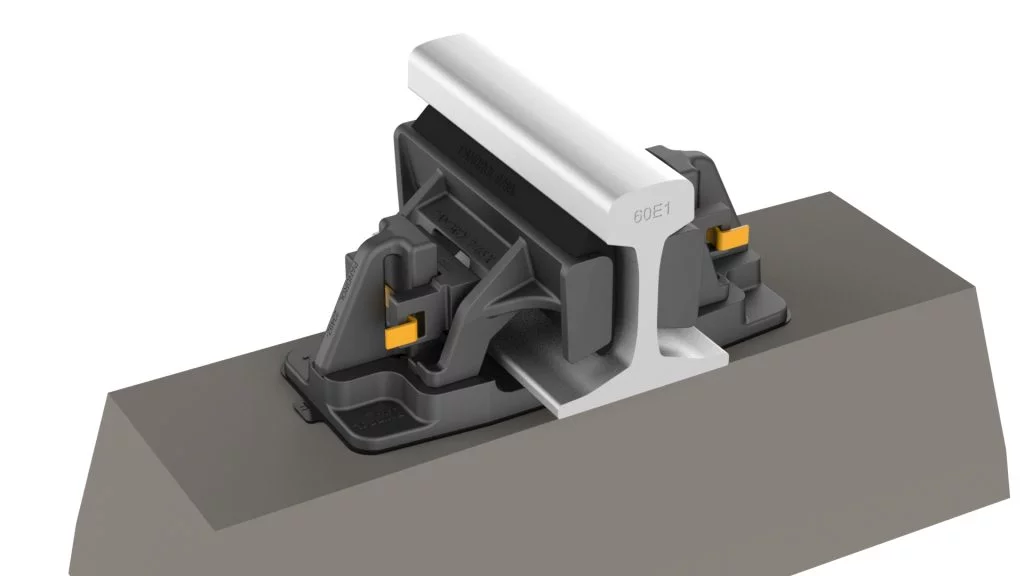

Gauge adjustment

Changing the size of the angled guide plates enables the rail to be moved laterally in the rail seat to achieve a wider or narrower gauge as required.

Captive fastening

The fastening can be pre-assembled on sleepers in the factory and transported as a complete unit. Once on site, the SKL clips simply need to be loosened and moved from parked position to working position after the rail has been threaded, then fully torqued up.

Removable dowels

Removable dowels are available as an upgraded specification, which can be replaced if they become damaged as a result of high-frequency use over time.

Clamping force

By simply reducing or increasing the installation torque of the screw within limits, the clamping force can be varied.

Track stiffness

By changing the rail pad, assembly stiffness can be modified between 50kN/mm and 500kN/mm.

Overturning stop

The clip’s central loop acts as an integrated safety mechanism that will only make contact with the rail when the clip arms are overloaded

Related products

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip