NABLA Tram Rail Fastening System

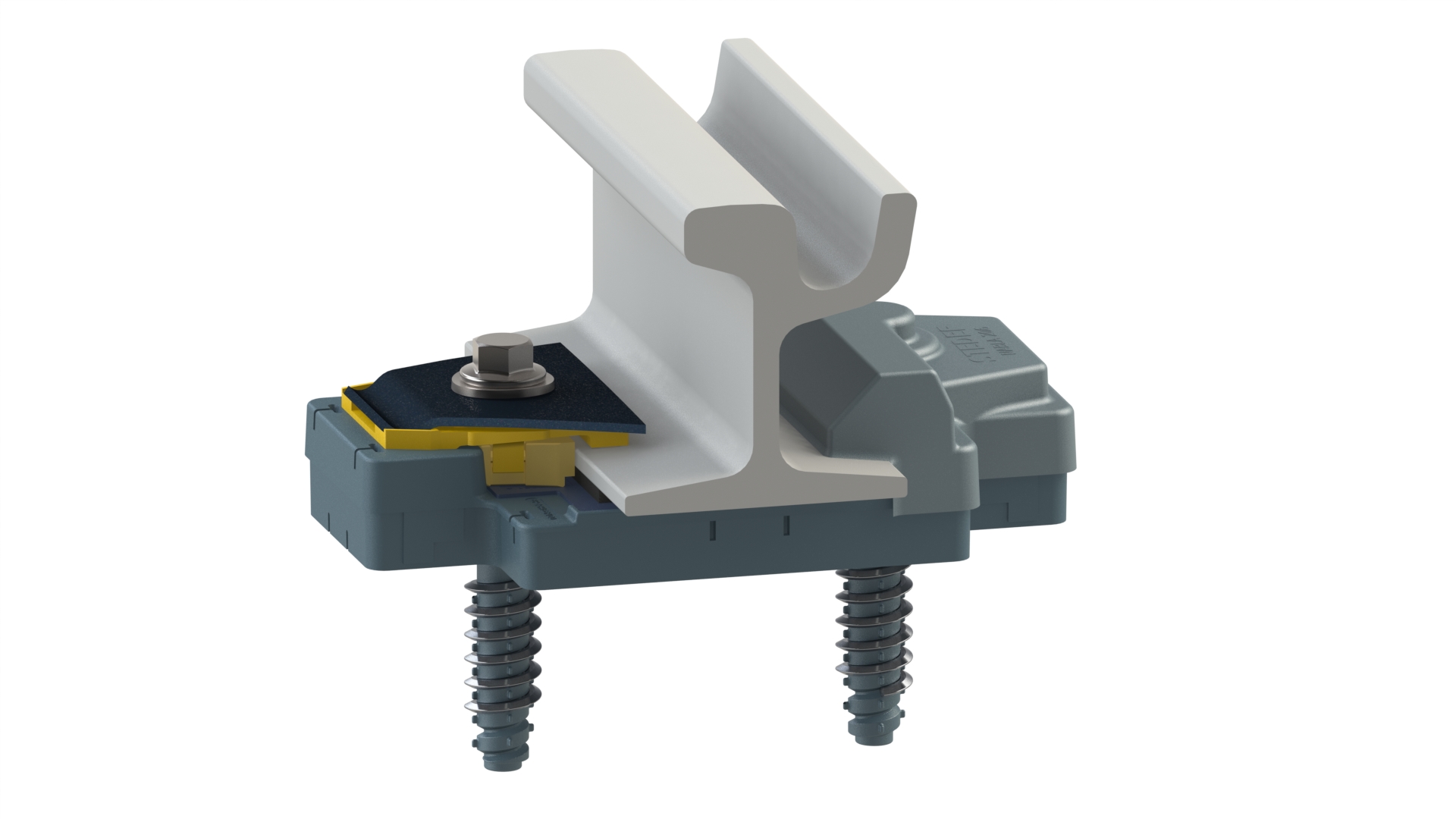

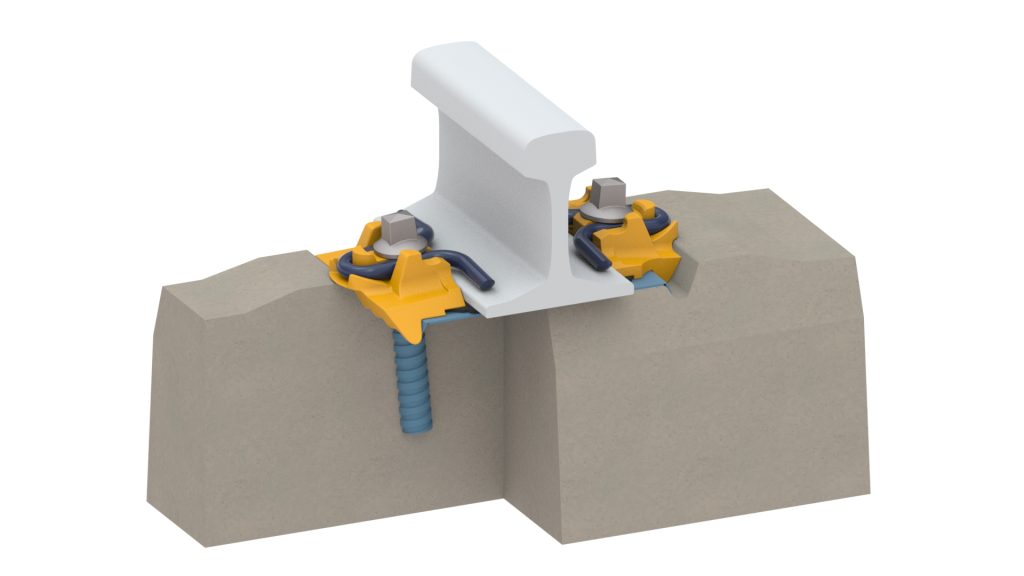

Pandrol’s NABLA Tram Rail Fastening is a cost-effective fastening system designed for trams and light rail systems. Comprised of a lightweight plastic baseplate and Pandrol’s reliable NABLA Evolution components, this fastening system combines ease of application with high performance to deliver impressive results every time.

NABLA Tram Explained

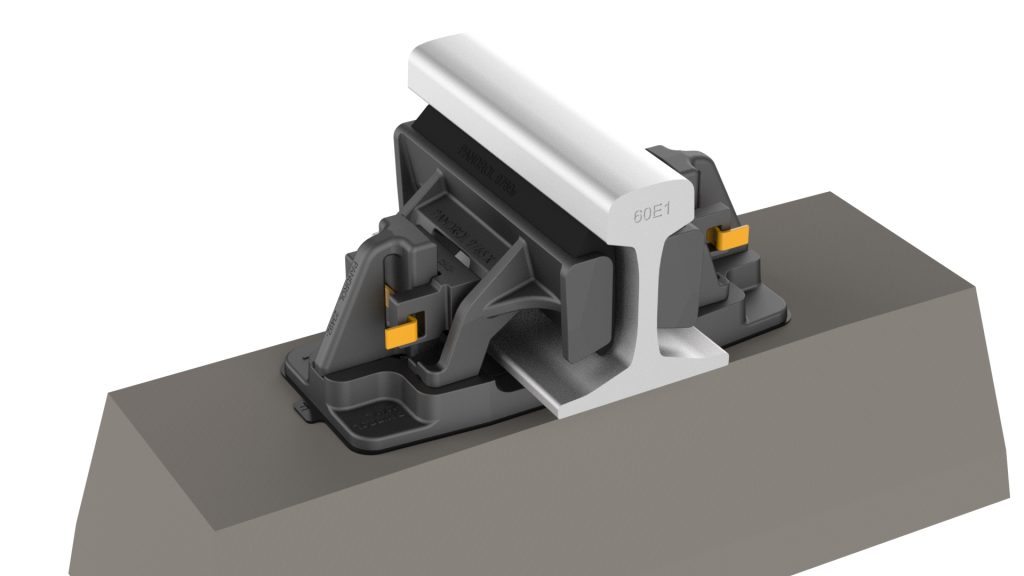

The NABLA Tram Fastening system conforms with EN Standard 313481-5, is suitable for use on non-ballasted slab tracks and has been installed over 250,000 times across European rail systems thanks to its compatibility with a range of project requirements.

Combining ease of application with high-performance levels, NABLA Tram is compatible with both top-down and bottom-up construction methods, depending on a project’s requirements. The baseplate is designed to allow effective insertion into a dry mix or fresh concrete, thanks to an air evacuation system consisting of blowholes and channels.

- Add value to your tram system with effective insertion into a dry mix or fresh concrete

- Suitable for top-down construction and bottom-up automatic construction

- Designed for use on state-of-the-art tramway track

Advantages of NABLA Tram

Easy installation

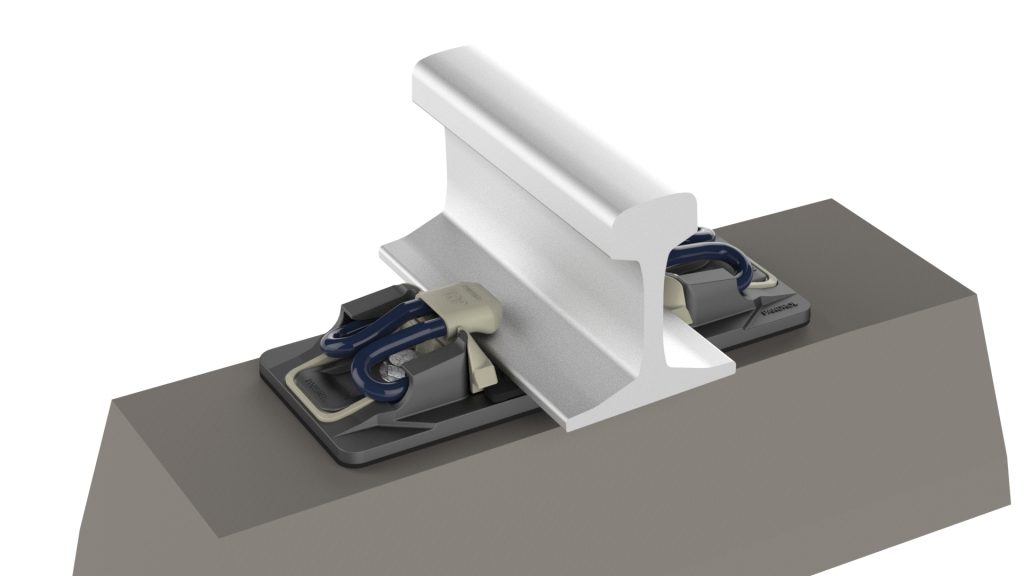

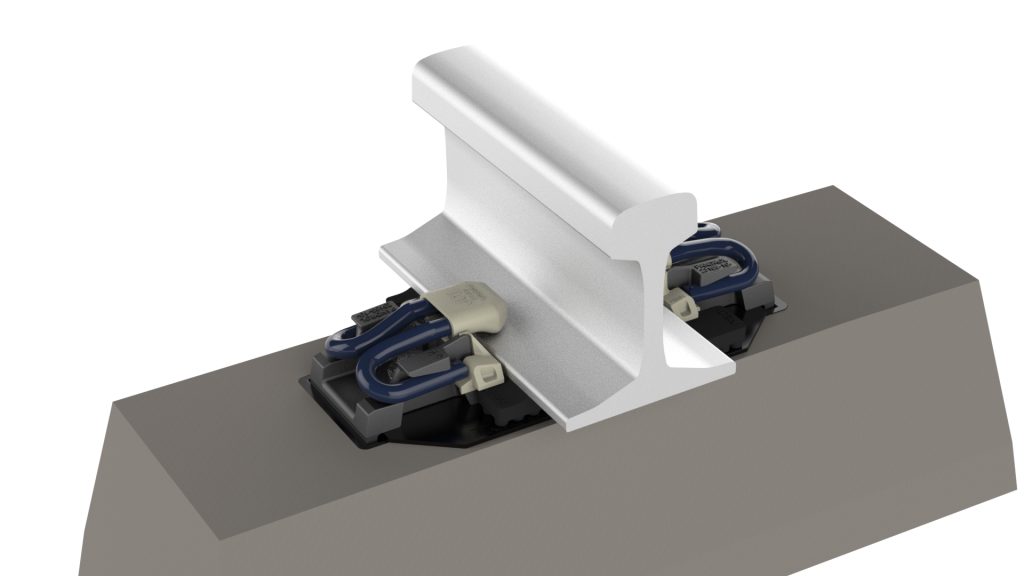

Install the NABLA Tram Fastening System with speed and ease thanks to its compatibility with both bottom-up and top-down construction methods. The system can be applied into either a dry mix or fresh concrete, so your tram line can be up and running as quickly as possible.

Enhanced compatibility

Increase insulation and rely on the NABLA Fastening System’s built-in protection. The system comes with covers that prevent concrete contamination and are compatible with grass, pavement, concrete and bitumen surfaces, making the fastening system suitable for tracks located in a variety of environments.

Reliability

The NABLA Tram Fastening System is known for Pandrol’s signature reliability. The system’s design includes a baseplate optimised to allow trapped air and water to escape, preventing weaknesses in the concrete fill and ensuring strength and performance for the rail system’s lifespan.

Good balance

Allow a good transfer of loads towards the concrete slab with the NABLA Tram fastening’s GS anchorage, which provides a pull-out resistance of 90kN and higher. The system is also suitable for use in conjunction with Pandrol’s QTrack sustainable resilient system for embedded rail.

Adjustability

This fastening system is suitable for a wide range of rail applications. Adjust the NABLA Tram Fastening System to provide a wide range of stiffnesses (from 35 MN/m up to 150 MN/m) and vibration attenuation better than -10dB.

Technical features of NABLA Tram

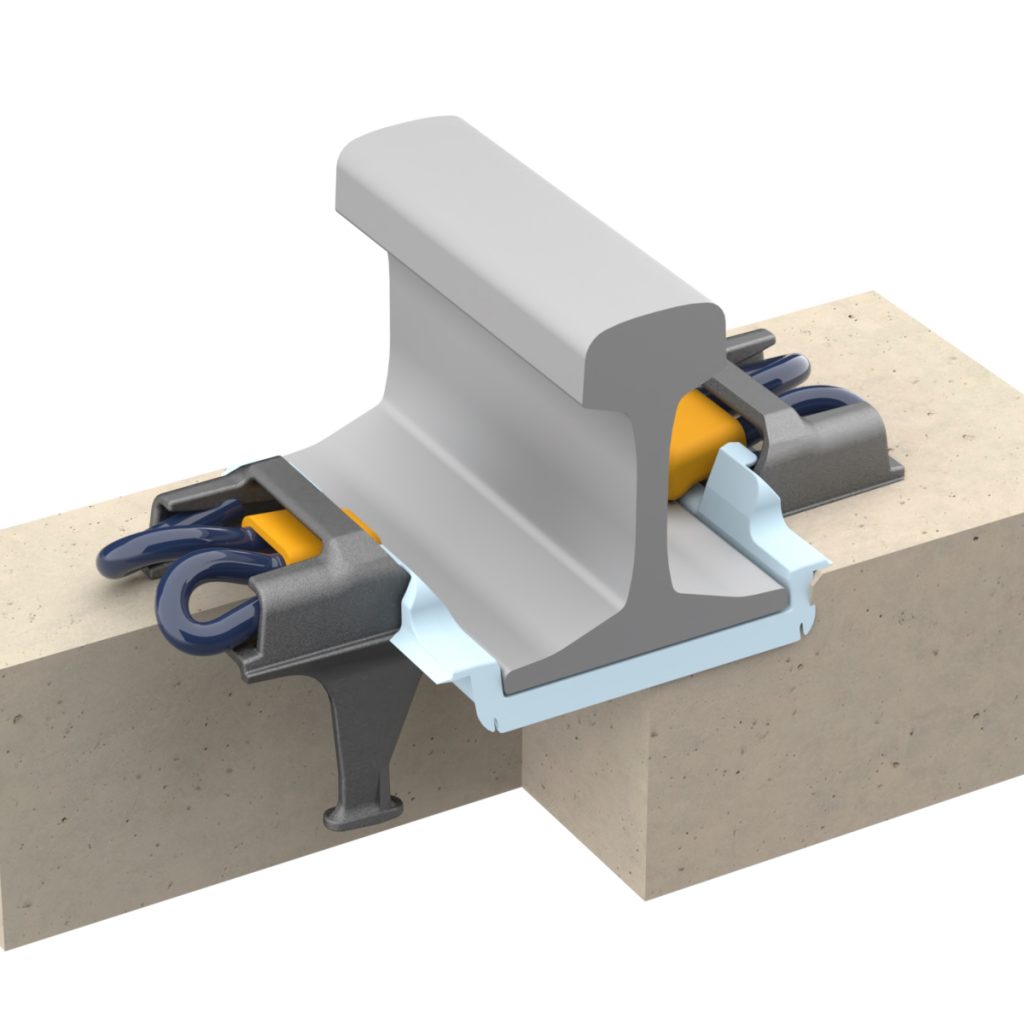

Embedded baseplate

The NABLA Tram Fastening System’s baseplate is partially embedded in concrete, allowing it to withstand lateral and longitudinal loading. The baseplate also allows trapped air and water to escape, ensuring a solid fill of concrete under the rail seat during installation.

Direct fastening

The Pandrol NABLA Tram is a direct fastening system. The rail is attached to the baseplate and the baseplate to the supporting base structure using the same method for strength, durability and reliable long-term performance.

Automatic installation

Speed up installation work with the NABLA Tram Baseplate system, which is optimised for automatic machine installation on slip-paved fresh concrete. Its shape, dimensions and weight allow for easy, economical installation.

Protective cover

Prevent concrete contamination and improve electrical, mechanical and thermal resistance with the Pandrol NABLA Tram Fastening System’s protective plastic cover, which allows for road traffic. The air evacuation system also prevents air from getting trapped under the baseplate.

Electrical insulation

Protect installation and maintenance workers with the NABLA Tram Fastening System’s 20 K Ohms + electrical insulation, which complies with EN13146-5:2012 standards and provides safety from stray currents.

Related products

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip

Vortok Coil

The rail seat assembly is typically made up of two tension clamps (SKL clips) on top of angled guide plates on each side of the rail.

SKL

This non-bonded, low-profile system is fully insulated and provides excellent stray current protection.

e-Clip SRS

NABLA Evolution is a direct rail fastening system that offers enhanced performance for tracks with tight radius curves. It has been proven in installations for several decades and is recognised for its simple installation and maintenance. By maintaining the track gauge, it significantly increases the life expectancy of assembly components.