Vanguard product overview

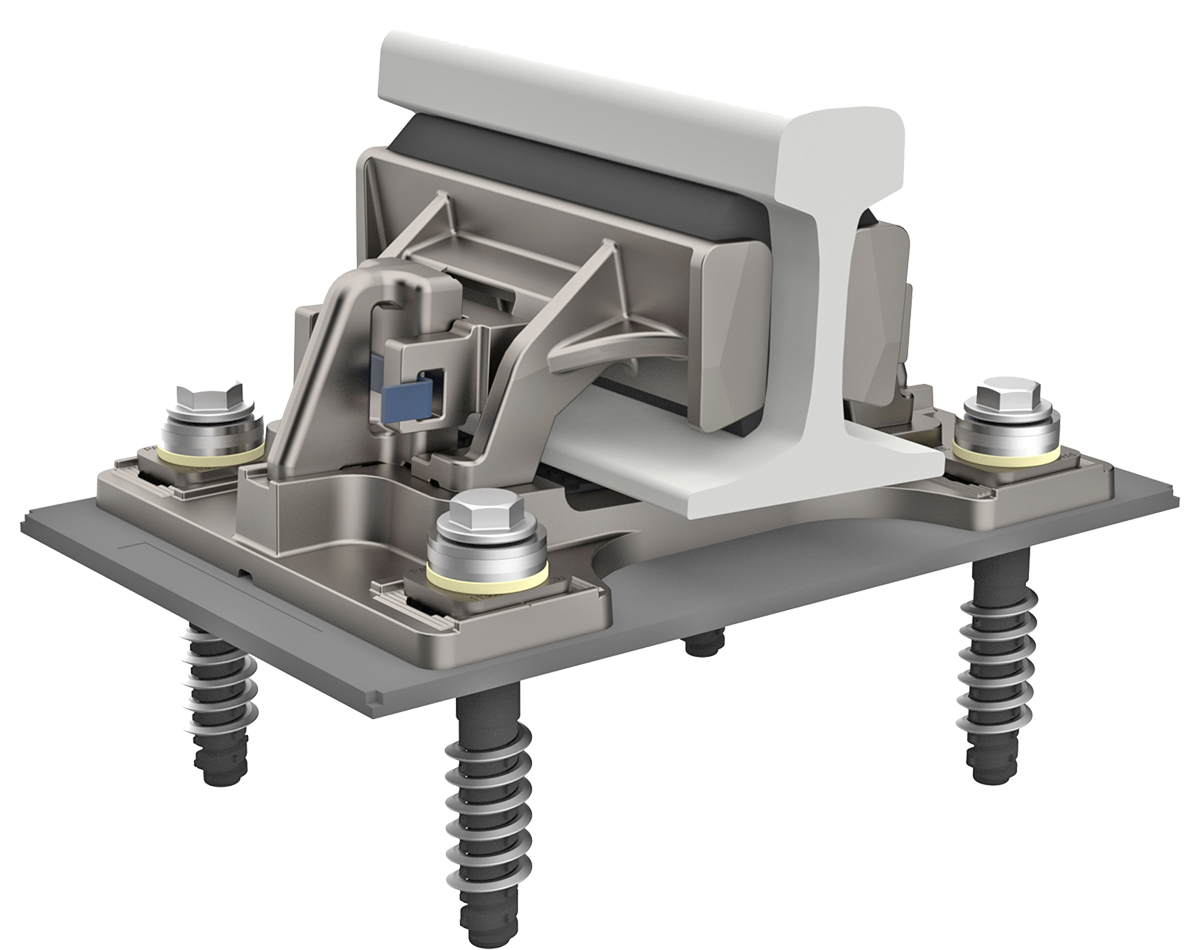

The Pandrol Vanguard rail fastening makes it particularly useful for addressing ground-borne, or secondary, noise and vibration issues in sensitive urban environments.

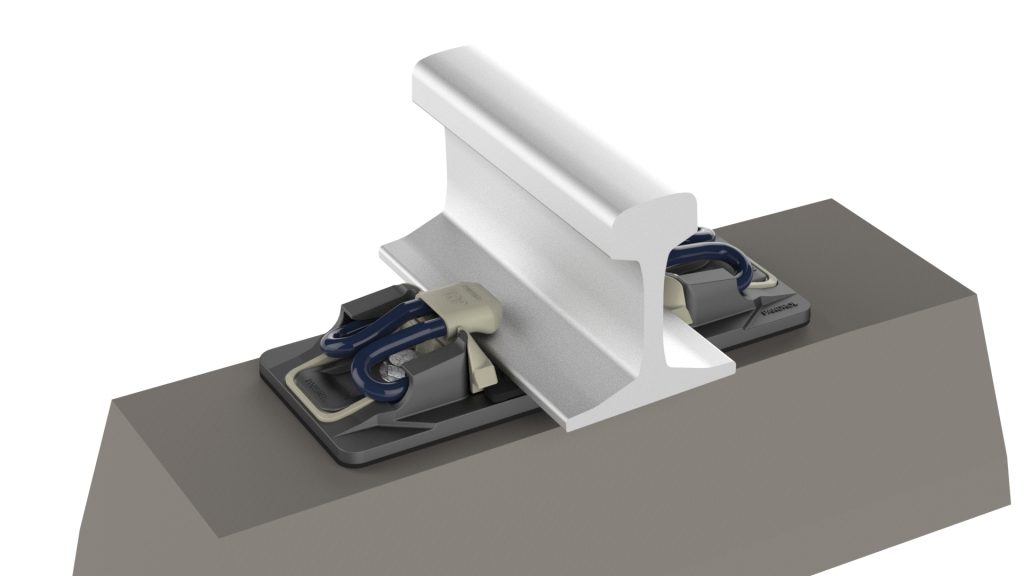

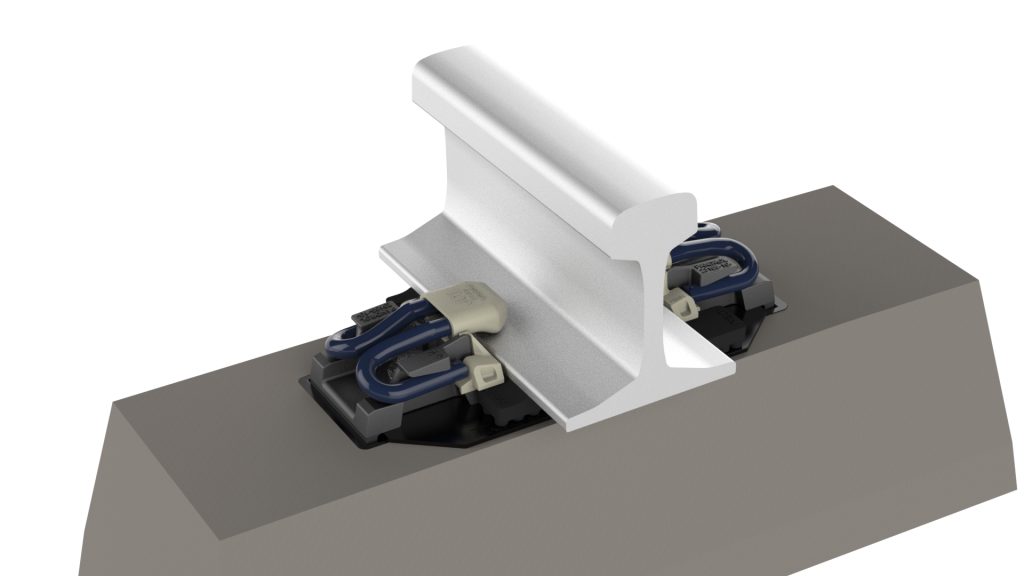

- Despite its low vertical stiffness, Vanguard has exceptionally high lateral stiffness and because the rail is restricted from rolling the dynamic gauge widening under traffic is minimised

- Generous lateral and vertical adjustment of the rail is possible, and maintenance is assisted by a Pandrol-supplied hydraulic clamping tool

- Vanguard can be retrofitted to existing track as easily as it can be installed on newly built track

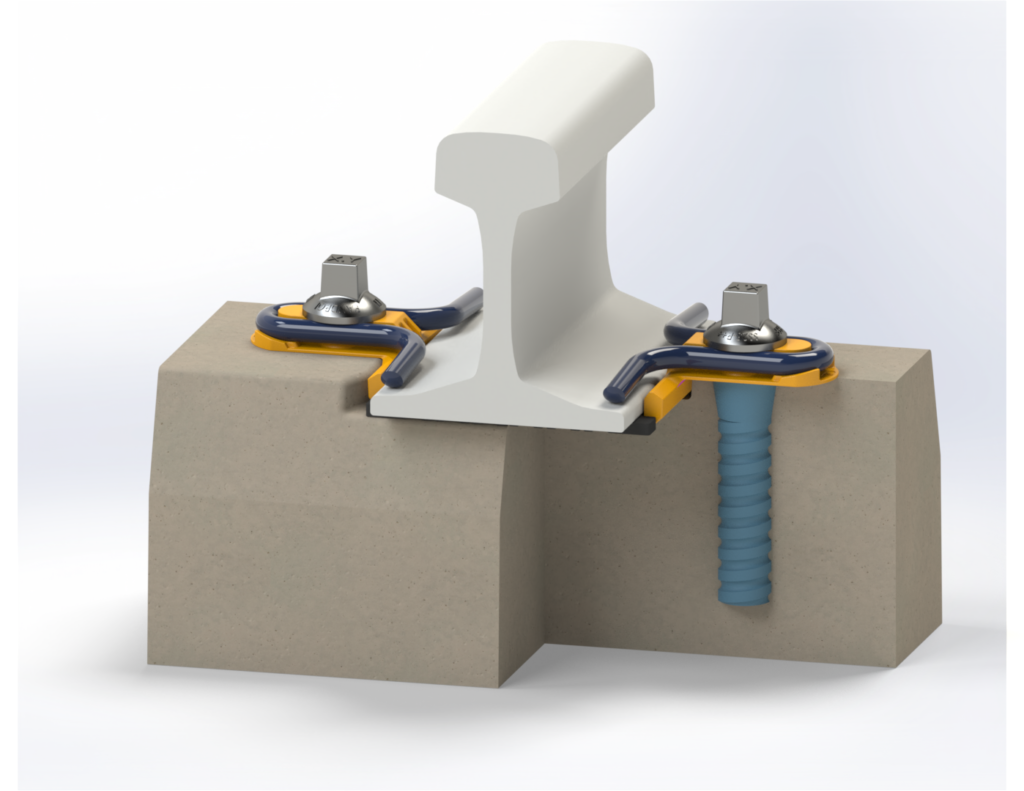

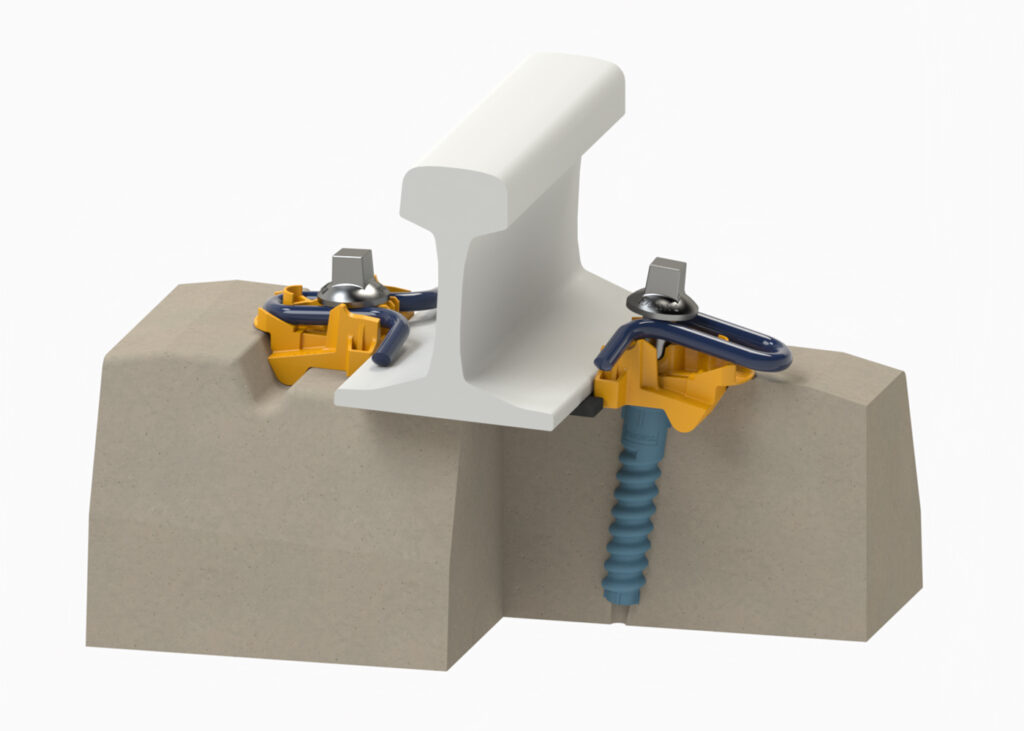

- Configurations are available for use with concrete sleepers, timber sleepers and slab track

Downloads

Benefits of the Vanguard

Money saving

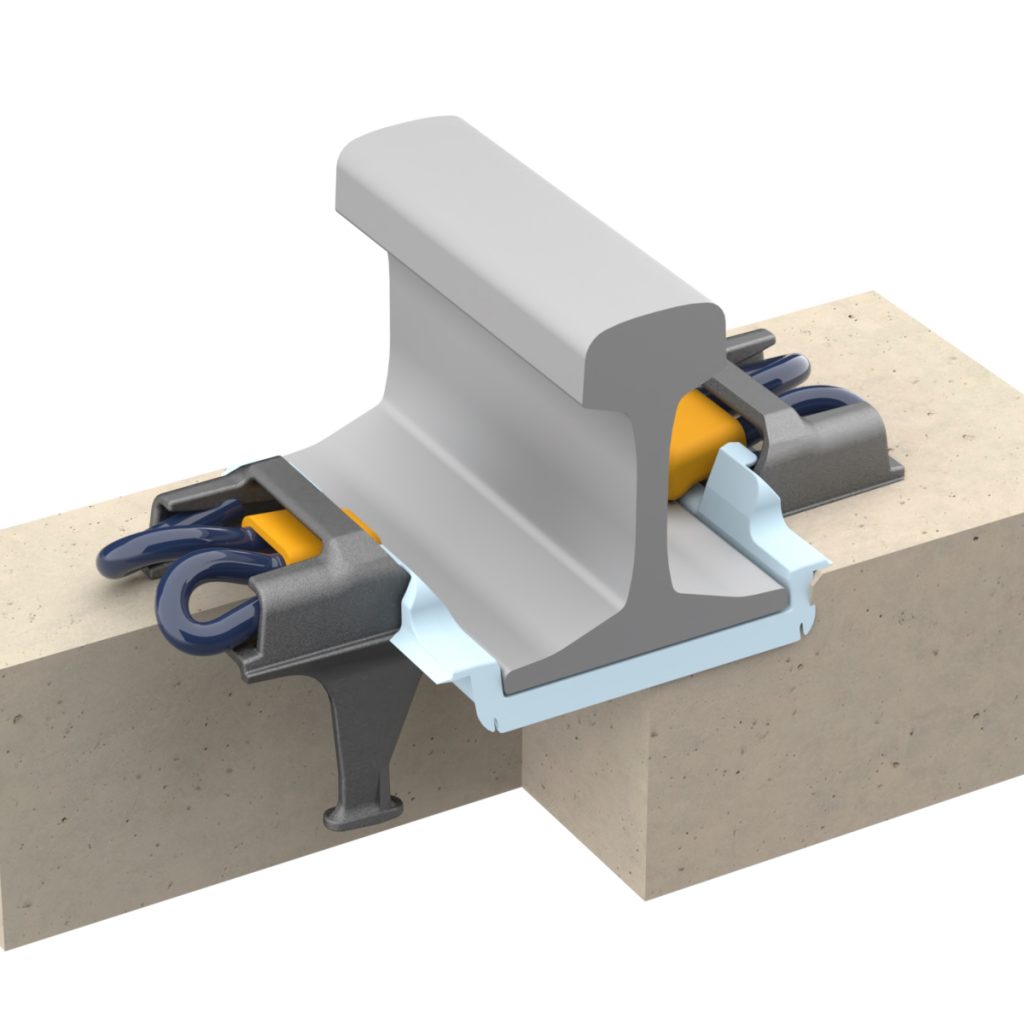

Not only does Vanguard provide a lower level of vertical stiffness than most other fastenings, it does so with a very low-profile rail level. This reduces overall track clearance heights, which can reduce construction costs significantly. It also makes Vanguard a very low weight solution compared to floating slab track.

Easily operated

Lateral adjustments can be made quickly, easily and without the need for any additional components. The bolts or nuts are simply untightened, the assembly moved laterally until it is in the required position, and the bolts or studs re-tightened. Where adjustment is not available in the baseplate, it can still be done by unclamping and moving the rail over before re-clamping.

Adjustable

Vertical adjustments can be made quickly, easily and without the need to fully disassemble the fastening by sliding the correct thickness shim, or combination of slims, under the assembly.

Accessible

Vanguard elastic components are easily accessible to maintenance technicians. Components can be inspected and maintained with simple hand tools.

Reduced vibrations

Almost all Pandrol baseplate products can be retrofitted with Vanguard. This makes it a unique and highly futureproof solution, enabling the reduction of ground-borne vibration at any time. As existing anchors can often be used, it is also possible to retrofit existing non-Pandrol fastenings.

Versatile

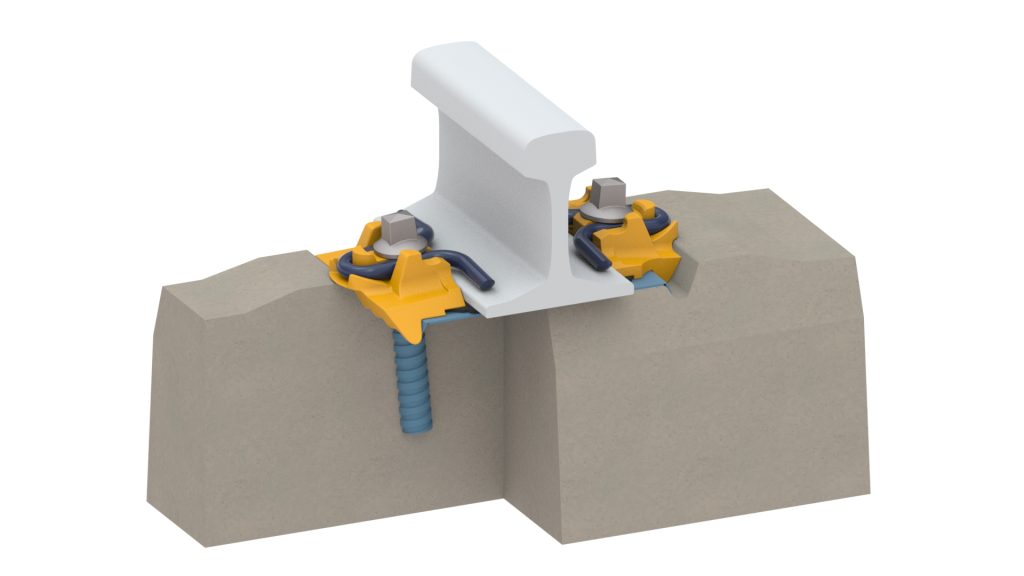

Vanguard can be used with all conventional track construction methods, including top-down wet pour (with or without pre-cast blocks) and bottom-up with pre-cast concrete blocks, sleepers and slab panels.

Technical features of Vanguard

Rail web support

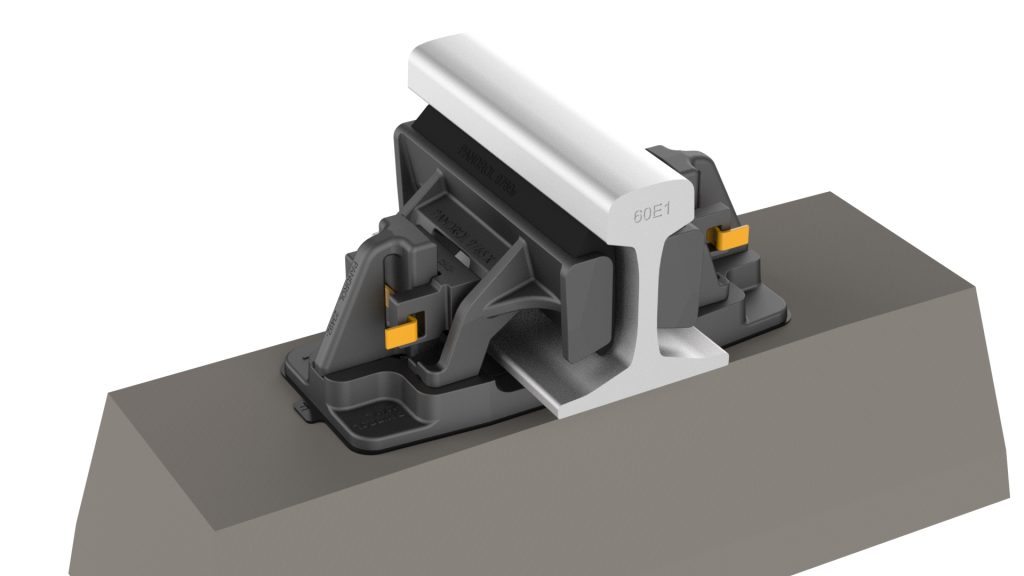

Unlike most fastenings, Vanguard supports the rail on the web under the head, instead of on its foot. This allows the rail to essentially hang in the air, with a resilient connection to the fastening in shear, rather than compression under the foot. As a result, exceptionally low vertical stiffness can be achieved.

Longitudinal restraint

Vanguard has been repeatedly proven to comply with longitudinal restraint requirements, with rail break gaps still being kept within limits. This is despite the shear connection between the rail and the fastening allowing for large elastic displacement.

Electrical insulation

Thick side rubbers that separate the rail from any metal, along with a rubber bump stop pad underneath it, provide very high levels of insulation.

Adjustment

Depending on configuration, fine lateral adjustment can be made via the baseplate as well as in the rail seat. Vertical adjustment is made by using shims under the baseplate.

Stiffness transitions

Combination of pads and shim are available and can be used under the rail by swapping out the bump stop to create a gradual stiffness step. This erases the transitioning between Vanguard and different tracks.

Track-structure interaction

Vanguard allows for large elastic rail displacement. As a result, large differential movement between track and structure is accommodated and most track-structure interaction effects are dealt with automatically.

Related products

Designed to be delivered preassembled on the sleeper or slab element, SD can deliver higher rates of construction thanks to its efficient controlled clip guidance from parked to the

in-service position.

Safe Driven (SD)

SD-E is the lightest version of the SD product family (up to 40% weight reduction).

SD-E

The system is characterized by a more compact and robust design with lower carbon footprint.

Its optimized geometry also enables automatic installation resulting improved efficiency and cost saving during installation and maintenance.

SD-RE

As its name suggests, the assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and DFC.

Vanguard Common Interface

As its name suggests, the fastening assembly fits on a common interface and is fully interchangeable with a range of fastenings, including FCA and Vanguard.

DFC Common Interface

The product can be pre-assembled and delivered to site captive on the pre-cast element, providing substantial cost savings.

FCA Common Interface

The SD-HH fastening system is quick and efficient to instal with few tools and minimal training.

SD-HH

The modern heavy haul railway is a demanding environment, with high locomotive horsepower, dynamic braking, large rail sections and high mega gross tonnes per year.

Victor Baseplate

Pandrol’s Fastclip FE RR rail fastening system is designed specifically for extreme heavy haul applications. It is suitable for an axle load of up to 40 tonnes and curve radius down to 150 metres.

Fastclip FE RR

The DRS baseplate is a double-resilience e-clip fastening system that is ideal for use on non-ballasted tracks when ground-borne noise and vibration reduction are required.

DRS Baseplate

Pandrol Fastclip is an established, highly-regarded resilient, threadless rail fastening. Over the years, the Fastclip family has grown to include the FC, FD, FE Fastclip products, each of which has been designed to meet the technical and commercial demands of a specific area.

Fastclip