VERSE (Stress Free Temperature Measurement)

Reducing the risk of derailment as a result of track buckles or rail breaks has long been a priority for railway companies and track engineers. Measuring the stress-free temperature of continuously welded rail is a key part of this, enabling weaknesses and risks to be identified and managed. In the past this was a time-consuming, expensive and often unreliable process that involved cutting the rail.

- VERSE® is an internationally accredited scientific instrument that is used to non-destructively measure the stress-free temperature of continuously welded rail.

- It has rapidly become an essential tool in modern rail stress management programmes and is now the most accurate and widely used stress-free temperature tool globally.

- Since 2002, it has registered over 200,000 readings – all accurate – and is now in use in over 20 countries worldwide.

Downloads

Advantages of using VERSE

Reduced maintenance

Because VERSE® eliminates the need to cut the rail to measure stress-free temperature, railway authorities are able to survey tracks in a fraction of the time needed for traditional methods. Typical testing time is 20 to 30 minutes for an experienced crew, depending on the type of rail fastening.

Highly accurate

The system ensures the highest level of accuracy through compensation for rail section geometric properties, rail wear, track curvature. It is the recognised industry standard for stress-free temperature measurement.

Instant result

VERSE® is easy and efficient to use. The handheld computer guides users through the measurement process and returns an instant trackside result.

Maximum flexibility

The small size and portability of the instrument means that it can be carried in a small estate car and easily deployed on site.

Improved safety

Early and accurate identification of track faults enables the correction of high-risk issues that might have been missed in the past. As a result, safety is improved through the avoidance of derailment caused by track buckles or breaks.

Cost-effective design

As VERSE® is non-destructive, efficient and accurate, it is extremely cost-effective. The actual process costs less than 5% of traditional methods of measuring stress-free temperature. Early identification and correction of problems results in increased track availability, better maintenance planning and expenditure, and reduced risk of litigation. All of these factors have a positive impact on the profitability and competitiveness of railway companies.

Technical features of VERSE

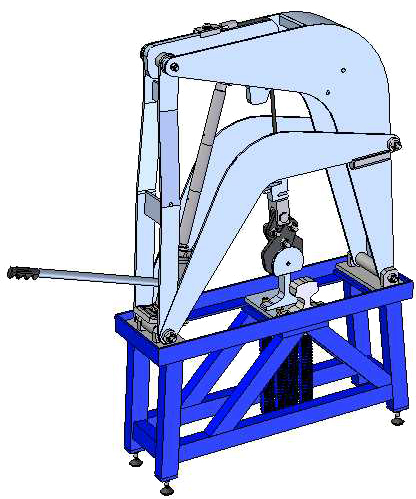

Clamp and built-in hydraulic jack

VERSE® incorporates a clamp to the rail head and a hydraulic jack that allow a section of unclipped rail to be lifted. Unlike with traditional methods of stress-free temperature measurement, the rail does not have to be cut.

Load and displacement transducers

A load transducer monitors the lifting of the rail and a displacement transducer logs the load and displacement at regular increments, accurately measuring the force and displacement profile of the deflection.

Handheld computer

A handheld computer guides the user through the rail deflection process and combines output from the transducers with other data (including ambient rail temperature, rail profile and height of the rail) to return an instant stress-free temperature trackside.

PC software

VERSE® is supplied with PC software and a database that can hold comprehensive data for a whole rail network. Data is transferred from the handheld computer to an office PC for storage and analysis.

Unaffected by residual stresses

VERSE® directly measures stresses in the rail and, unlike other systems, is not affected by residual stresses formed when the rail was manufactured. This makes it convenient to use across a varied infrastructure.

The recognised standard

The VERSE® system is the recognised industry standard. It has been evaluated by a number of independent railway research institutes, including British Rail Research, Transportation Technology Centre Inc. (subsidiary of Association of American Railroads) and Railway Research Institute, Czech Republic.

Handheld Computer

The output from the load and displacement transducers incorporated in the VERSE® system are routed via a dedicated signal condition system to a handheld computer, which then returns an instant stress-free temperature result trackside. The device also guides users through the measurement process.

Related products

SonicVizio-WS-S is a trolley used in rail flaw detection on any type of track. Equipped with a 5 angled probe 40/70/0TR/40/70°, it allows the detection and characterization of internal defects inside rail, weld and all components of the track.

SonicVizio-TR-S

Characteristics, metrics analysed, SonicVizio-WS-S is a lightweight system used in rail flaw detection on any type of track. Equipped with a 5 angled probe 40/70/0TR/40/70°,

it allows the detection and characterization of internal defects inside rail, weld and all components of the track.

i+detect (SonicVizio-WS-S)

Developed in partnership with Amberg Technologies, Pandrol’s GeoVizio-TR-Smart is a new smart track geometry trolley for measuring the quality of track. It is an innovative track geometry trolley that quantifies the condition of track and determines Track Quality Index, as required in the new European Standard EN 13848-6.

GeoVizio-TR-Smart

We offer a range of solutions for different applications, allowing the user to take height and distance offset readings from the running rails to a desired object or position such as a Platform or Datum Plate.

Structure and Clearance

Pandrol’s Track Geometry Trolley is a dedicated device for recording track gauge, cant, twist, distance, and GPS positioning of the track. It has been designed to be quickly and easily assembled on-site without the need for tools, instantly providing live data and allowing rapid identification of problems in the track.

Track Geometry Trolley

The entire portfolio of Overhead Line Equipment easily folds up, and is ergonomically designed.

Overhead Line Measurement

The gauges have been designed with a sprung gauging foot, with all measurements being displayed on the end of the gauge, ensuring accurate measurements and minimising user error

Track Geometry Gauges

This comprehensive test is carried out on the head, web and foot to provide a detailed analysis of the entire weld.

Weld Inspection

Ultrasonic rail testing is a full-track inspection solution that uses high-pitched waves to scan rails and identify internal flaws in need of repair. Pandrol teams are experts in the application of ultrasonic rail inspection, and our certified inspectors can provide comprehensive training tailored to your infrastructure, setting, and use case.

Rail Ultrasonic

Identifying points of undulatory wear on the rail head will outline where grinding actions need to be taken to prevent further deterioration.