Rail Stressor TR75

Carry out stress relief or replacement of continuously welded rails (CWRs) with ease and convenience using the Pandrol Rail Stressor TR75. This high-quality rail stressor product is an essential piece of maintenance equipment for any rail system, thanks to its versatility and efficiency-boosting capabilities.

Rail Stressor TR75 Explained

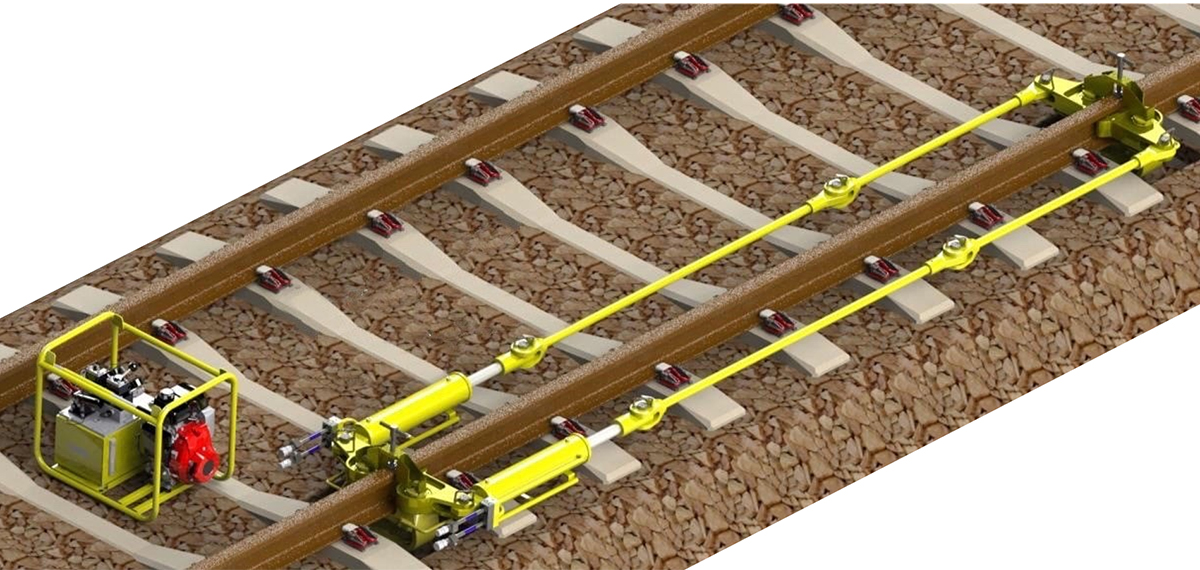

The Pandrol Rail Stressor TR75 is used during maintenance works to stretch long welded rails before aluminothermic welding and to secure the tensioned rail while cutting. It is also capable of joining and maintaining a constant gap between the two rail ends.

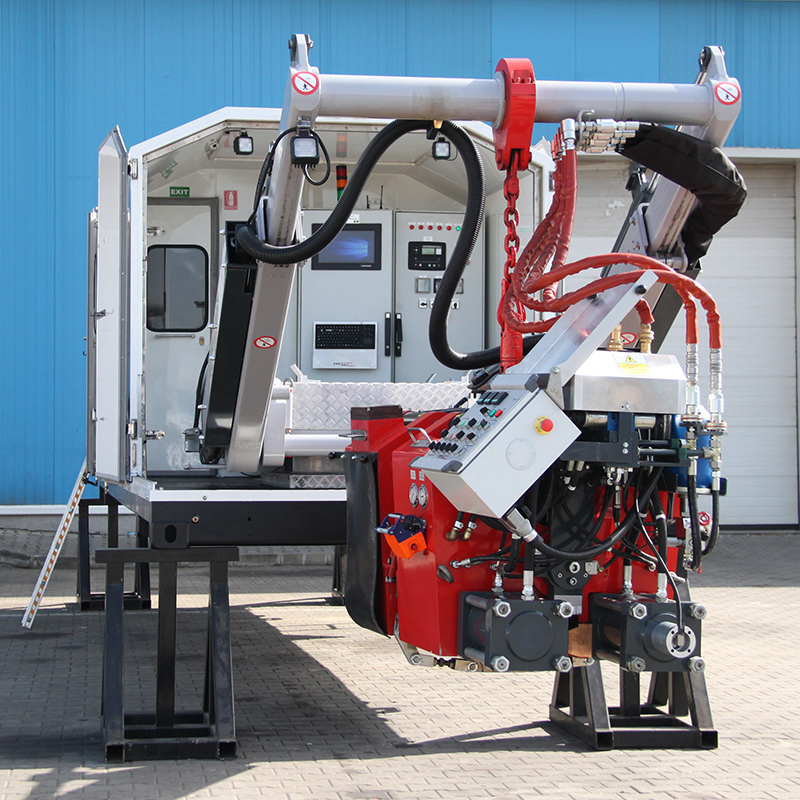

Fitted with a hydraulic power unit and an integrated hand pump, the Rail Stressor TR75 is flexible enough for use in any rail setting, including tunnels and urban areas.

- Hydraulic power and an integrated hand pump

- SNCF homologation (Nr DEO 19280)

- Optimised for fast installation

Downloads

Advantages of the Rail Stressor TR75

Increased efficiency

Reduce downtime and boost the efficiency of rail stressing with the Rail Stressor TR75. Pandrol’s rail stressor model can be set up under the rail without obstructing the rolling surface so trains and vehicles can keep circulating throughout the stressing process. In addition to its time-saving properties, the Rail Stressor TR75 can be installed and operated by just two workers, saving resources and labour.

Enhanced safety and security

Ensure safe and secure operations with the Rail Stressor TR75’s hydraulic pumps, which increase stretching force steadily to reduce the risk of accidents. When combined with the model’s hand pump operation, which reduces hydraulic pressure gradually, Pandrol’s Rail Stressor provides accurate and safe rail adjustment over the last few centimetres.

Ease of use

Set up the Pandrol Rail Stressor easily and quickly by just two people, thanks to its yoke and pin assembly. When the speed of set-up is a special priority, the Rail Stressor TR75 can be installed even faster above the rail head on certain rail types.

Flexibility and versatility

Unlock flexible operations with the help of the Rail Stressor TR75’s hand pump operation. This feature generates zero gas emissions and little noise, making it ideal for rail stressing in environments where restrictions apply, such as in tunnels and urban areas.

Technical features of the Rail Stressor TR75

Powerful engine

Operate at full capacity with a four-stroke engine that produces 2.2 kW of power at 3,600rpm. The Rail Stressor TR75 is fuelled by a 1.2-litre capacity petrol tank and has a 0.4-litre oil tank for efficient and effective operation.

Hydraulic system

Rely on the Pandrol Rail Stressor’s automatic flow and pressure adjustments to provide the required force for your stressing project. The high-performance two-speed pumps and 15-litre capacity hydraulic unit oil tank are built for the job.

Hand pump

Maximise the versatility of your rail stressing operation with the Pandrol Rail Stressor’s hand pump feature. The hand pump is integrated into the hydraulic power unit, acting as a backup system, and allowing for accurate adjustment of the rail over the last few centimetres while releasing hydraulic pressure from the hoses. The Rail Stressor TR75 is also suitable for use with a separate hand pump unit.

Clamping arrangement

Achieve a secure and reliable hold on the rail before and during stressing with the Rail Stressor TR75’s unique clamping arrangement. Four clamps are positioned on the web of the rail. These clamps then gradually increase the grip on the rail during the tension phase for a secure hold.

Adjustable stroke

Adjust the length of the rail stressor with three different rod lengths, ranging from 1.2 to 1.8 metres, including insulated and adjustable tie rods. These can be quickly mounted and changed to adapt the machine to any type of situation.

Related products

This lightweight and portable grinder is specially designed for finishing grinding after rail welding on track. The integrated lithium battery provides autonomy, as no other power source is required.

Battery-Operated Handheld Grinder B115

The revolutionary i+align automatic aligner has been designed to transform rail welding through precise, automated rail alignment.

i+align

Designed to screw/unscrew all types of bolts and drill holes in wooden sleepers, this high-efficiency tool is powered by a specially designed engine that ensures accurate, quick, reliable operation.

Impact Wrench Master 35

The equipment can be used for normal gap, wide gap and head wash repair (HWR) welding.

i+cool

Performing checks and adjustments is an important part of the welding and maintenance process, particularly on the ends of rails.

Straight Edges RAP1000, RB500, RB700 and RB1000

Designed to operate with the included battery-operated non-impacting drill, the simple chuck attachment allows easy installation of the shear so it is quickly operational on the track.

Compact Shear B-M-VIR

Excess metal remaining above the rail head during welding was traditionally removed manually with a hammer and chisel. The Weld Shear Hand Pump automates this process and reduces the risk of damaging the rail.

Weld Shear Hand Pump EPM2

quipped with a fail-safe braking system and supplied with a detachable brake and push handle, the Rail Lorry has a stand-alone, load-bearing rolling platform for use on track

Rail Lorry PL01 and PL01.5

The HFP 36V is battery powered and fully automated for easier, more reliable operation: the ignition, timing and stop require no manual interference or flame adjustment.

High Flow Preheater 36V

Pandrol offers a complete mobile flash butt welding plant hire service for rail companies, to complement our aluminothermic welding solutions in India. The service involves providing access to a flash butt welding machine, along with a trained team of operators to carry out the welding process to a high standard.

Flash Butt Welding

During aluminothermic welding, a deadhead of excess metal remains above the rail head. This was traditionally removed manually with a hammer and chisel. The Monobloc Electrical Weld Shear automates this process and removes the risk of damaging the rail.

Monobloc Electrical Weld Shear EME1/EME2

During aluminothermic welding, excess metal remains above the rail head. This was traditionally removed manually with a hammer and chisel.